Roller coating device

A technology of roller coating mechanism and lifting mechanism, applied in the field of machinery, can solve problems such as uneven roller coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

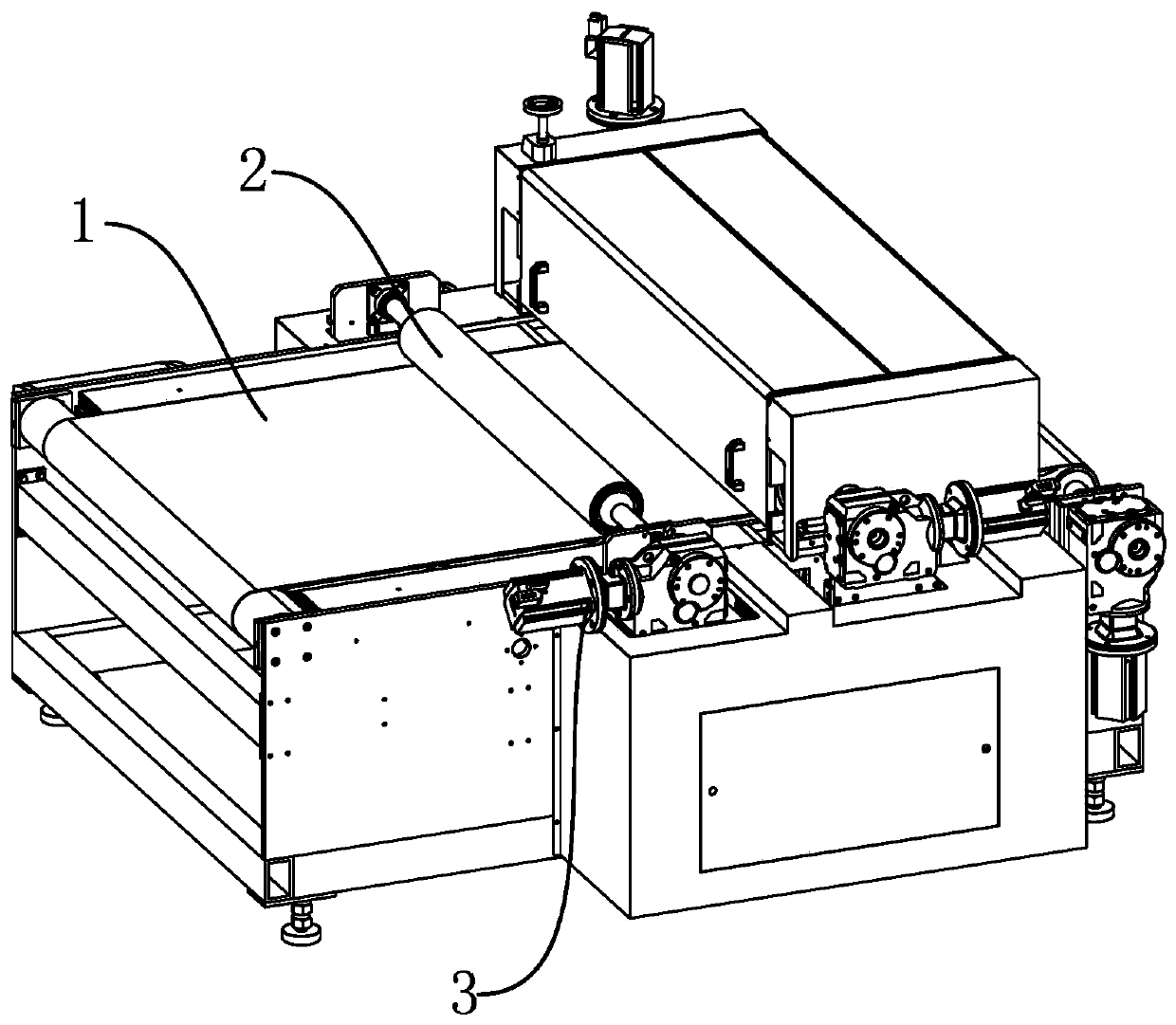

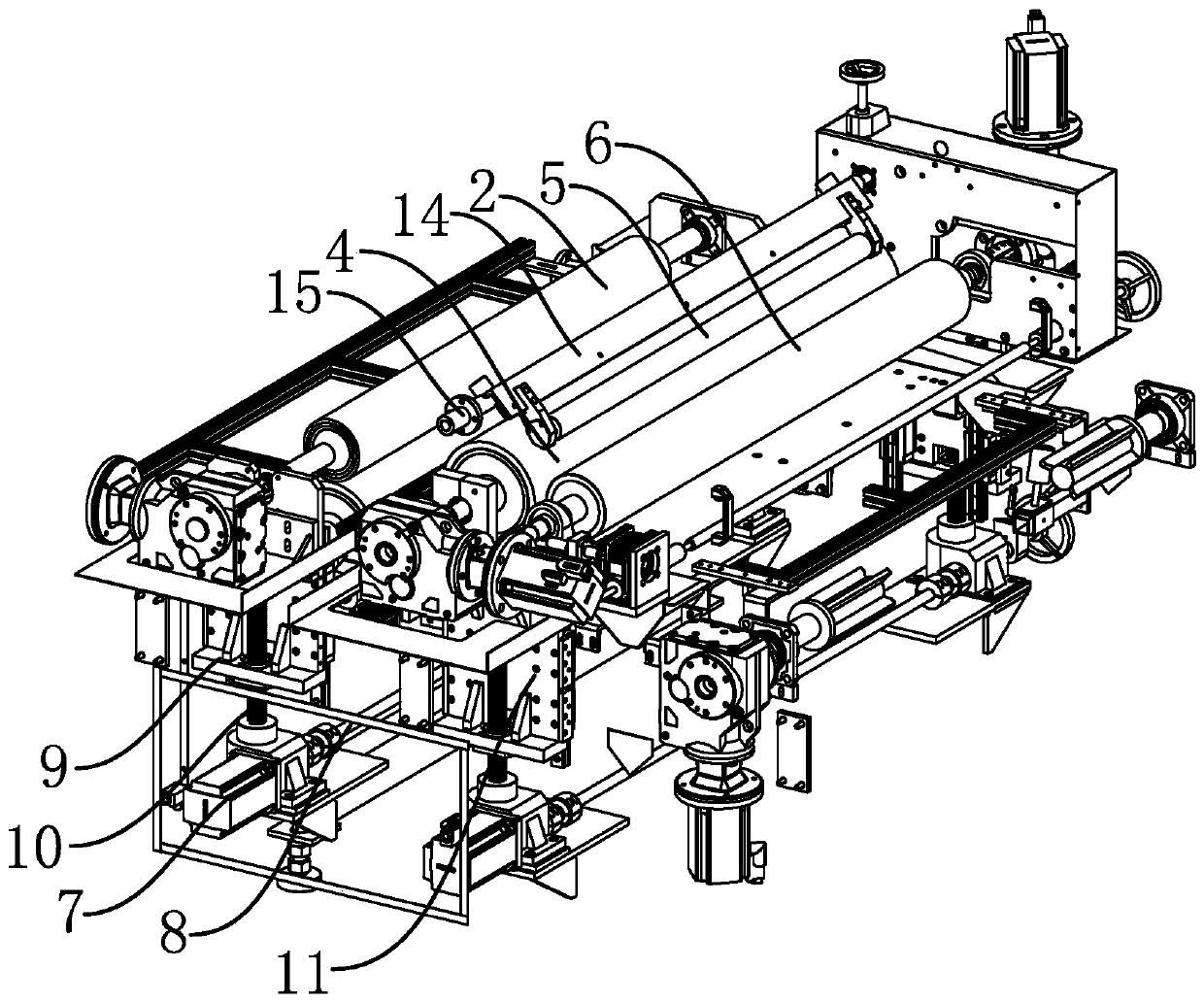

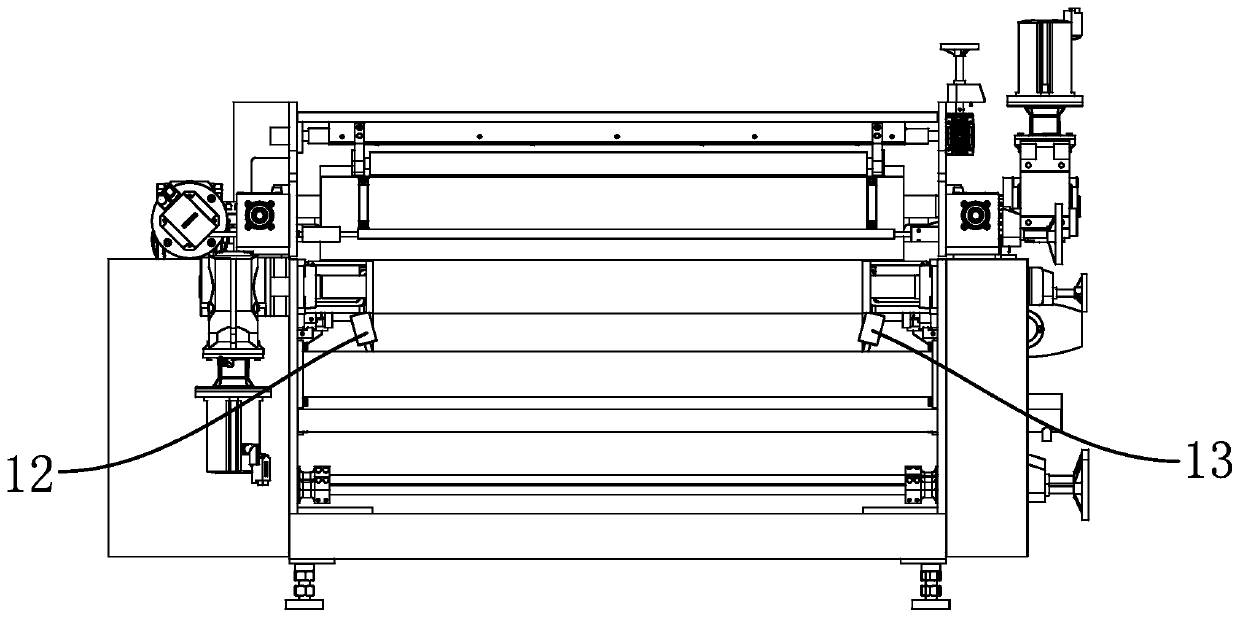

[0018] like Figure 1-3 As shown, a rolling coating mechanism device includes a frame, one end of the frame is a feed end, the other end of the frame is a discharge end, and a rotatable conveyor belt 1 is provided between the feed end and the discharge end. , the top of the conveyor belt 1 is provided with a pressure roller 2, the end of the pressure roller 2 is connected with a drive motor 3 that can make it rotate in the circumferential direction, and the frame is provided with a lifting mechanism 1 that can drive the pressure roller 2 to move up and down. Also be provided with coated rubber roller 4, feeding roller 5 and engraved pattern roller 6 by the fixed mode of 8 directions of circumferential rotation shaft, be pr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap