Sheet material stacking device

A material and flake technology, which is applied in the field of sheet material stacking devices, can solve the problems of affecting the stacking of sheet materials, easy to float upward, and prolonging the time of falling into the stacking tank, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

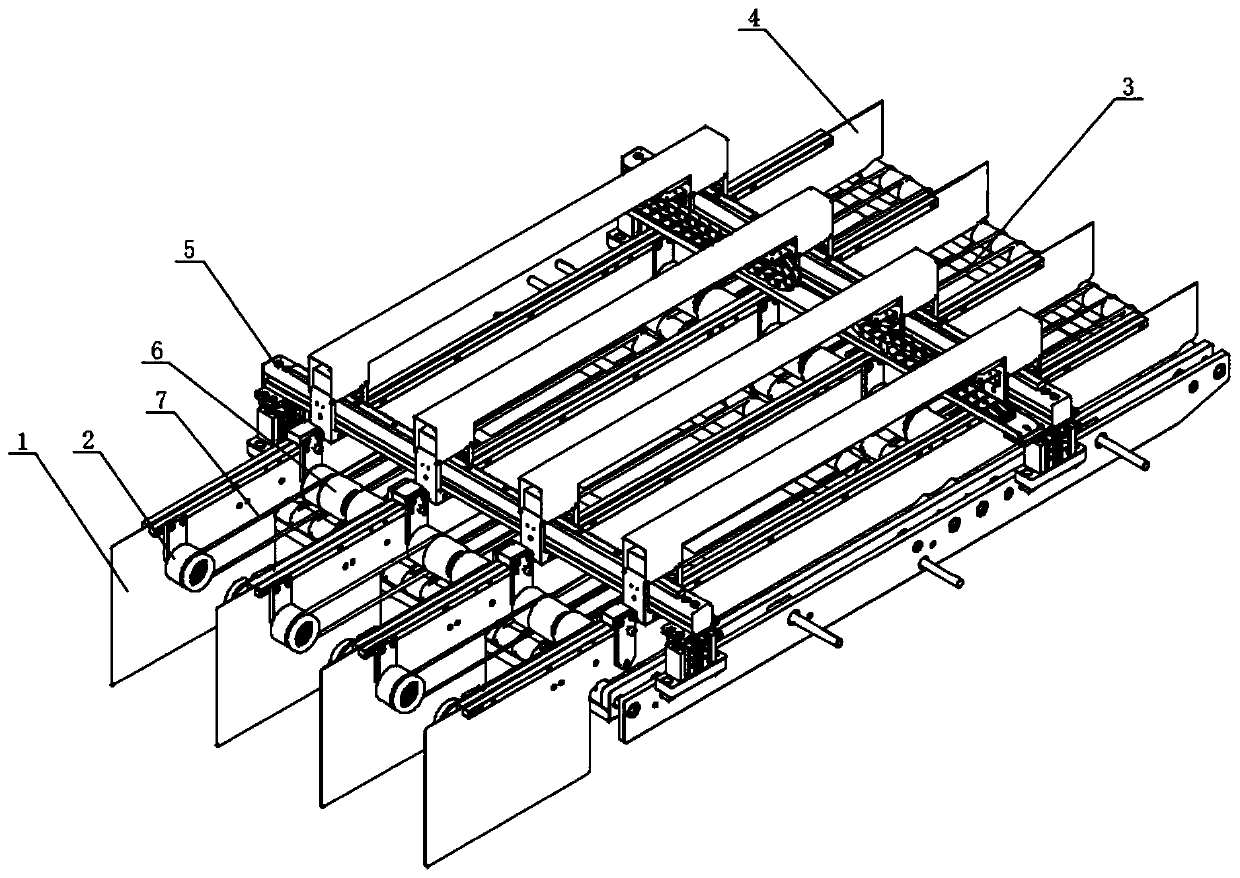

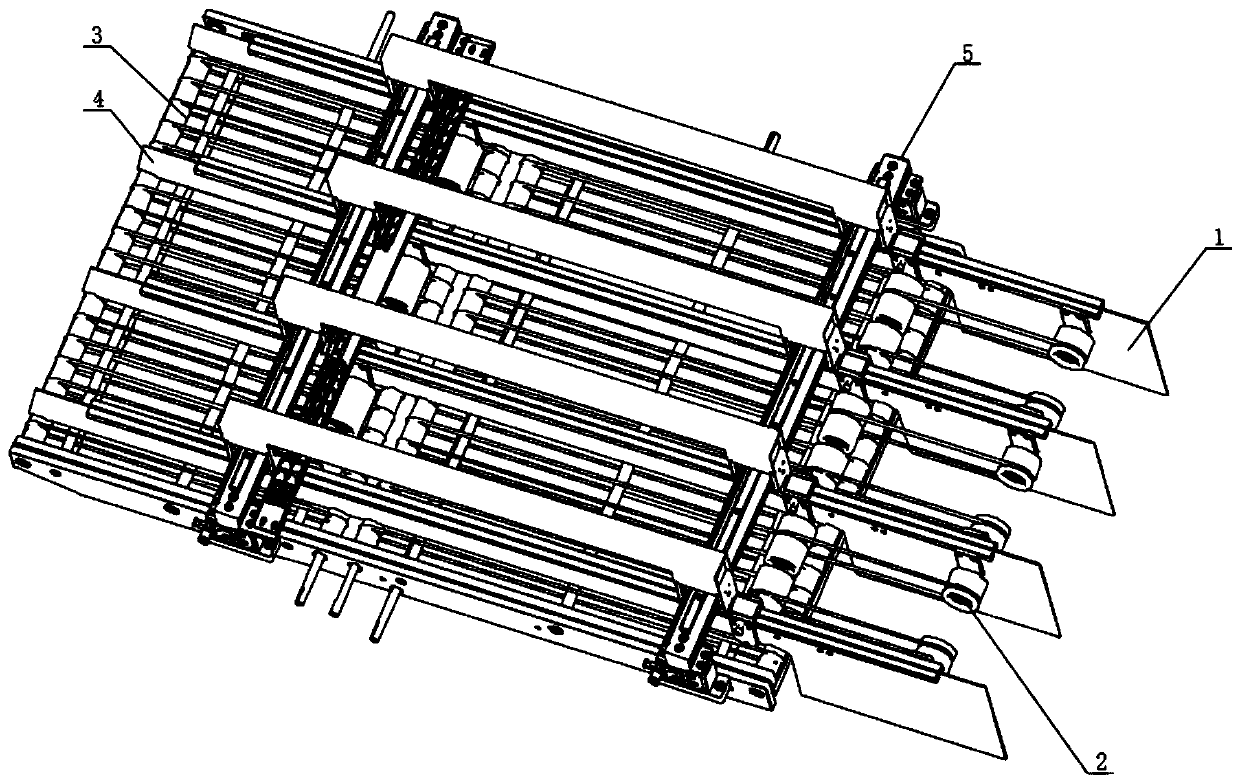

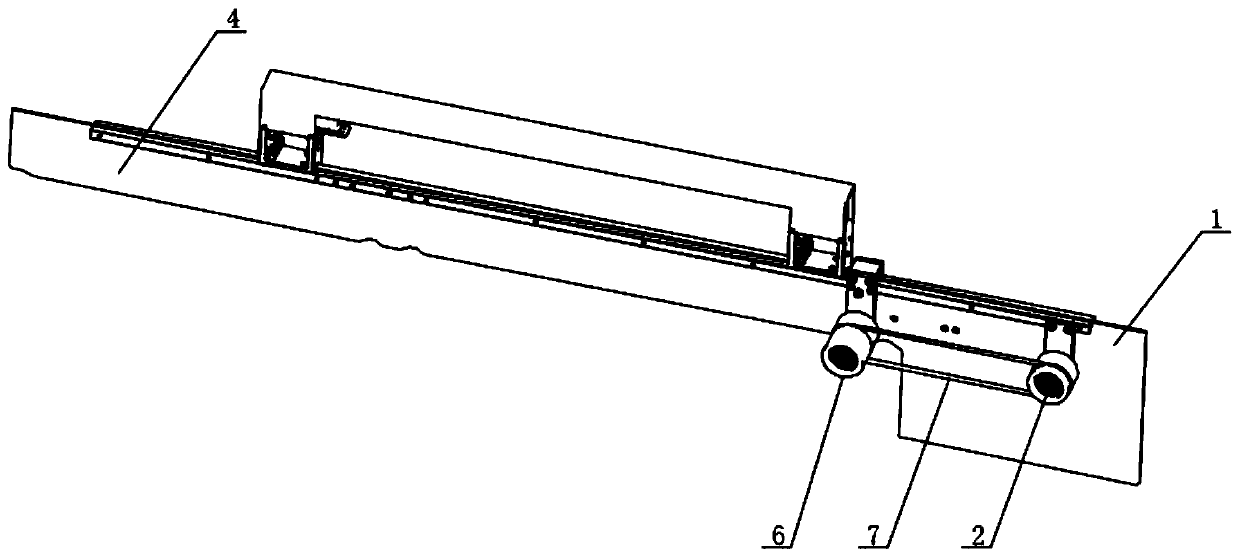

[0029] The branch transmission device of embodiment 1 such as Figure 1 to Figure 3 As shown, the stacking device includes stacking baffles 1, and the stacking baffles 1 are arranged vertically opposite each other to separate stacking slots. The stacking device also includes a pressing wheel assembly 2, and the pressing wheel assembly 2 is located in the stacking slot Inner for pressing sheet material down towards the stacking chute. When a single piece of sheet material is transported to the stacking tank, the pressure wheel assembly 2 prevents the sheet material from floating upwards, so that the sheet material falls into the stacking tank stably, controlled and quickly for stacking, ensuring orderly stacking.

[0030] As a preferred solution, the stacking device also includes a transmission mechanism 3 and a shunting baffle 4, the stacking baffles 1 are vertically opposite to each other and parallel to the conveying direction of the transmission mechanism 3, the stacking ba...

Embodiment 2

[0038] The difference between embodiment 2 and embodiment 1 is that the structure of the pressure roller assembly is different: in embodiment 2, the pressure roller assembly includes a pressure roller, the pressure roller is a cylindrical pressure roller, and the axial direction of the pressure roller is vertical for stacking baffles.

[0039] The pressure wheel assembly is a pressure wheel that does not include a belt in this embodiment, and several pressure wheels can be provided, and can extend from the stacking groove to the transmission mechanism, so that the pressure wheel blocks the sheet material from floating upwards, and quickly Falling into the stacking groove and stacking can also achieve the purpose of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com