An intelligent construction machine for retaining walls in geotechnical engineering

A geotechnical engineering and retaining wall technology, applied in water conservancy engineering, infrastructure engineering, construction and other directions, can solve the problems of low work efficiency and labor consumption, and achieve the effect of convenient and quick replenishment and ensure the quality of laying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

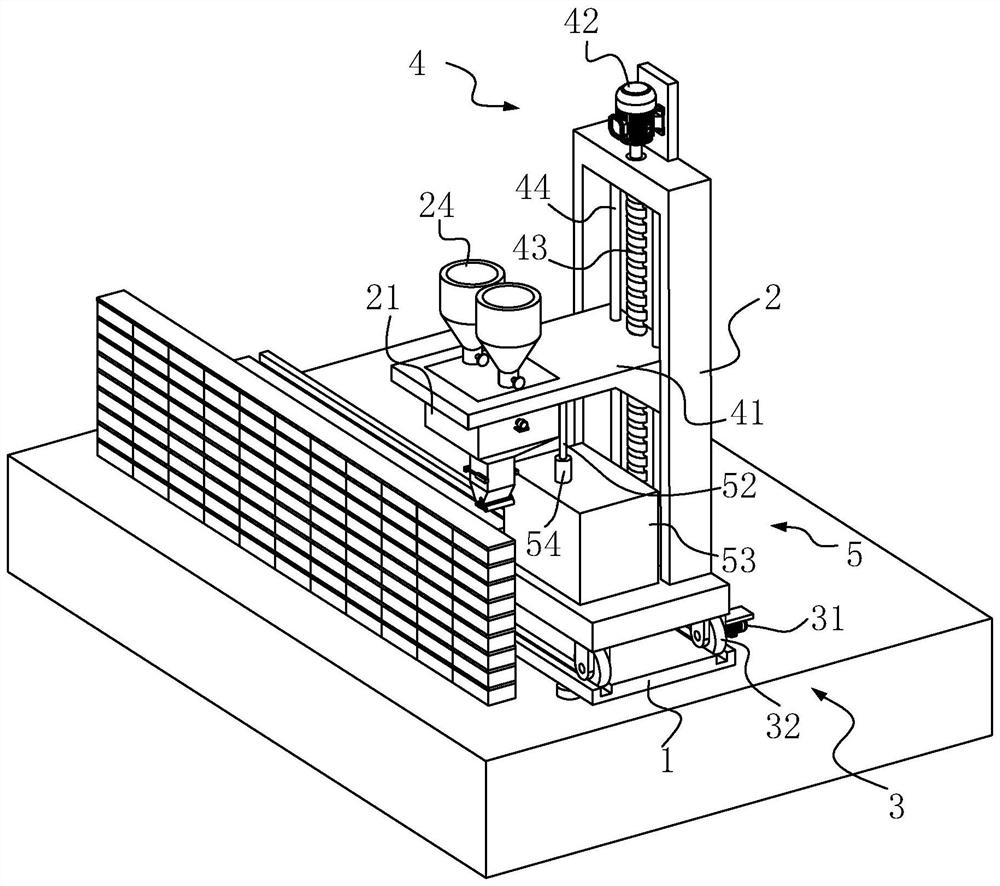

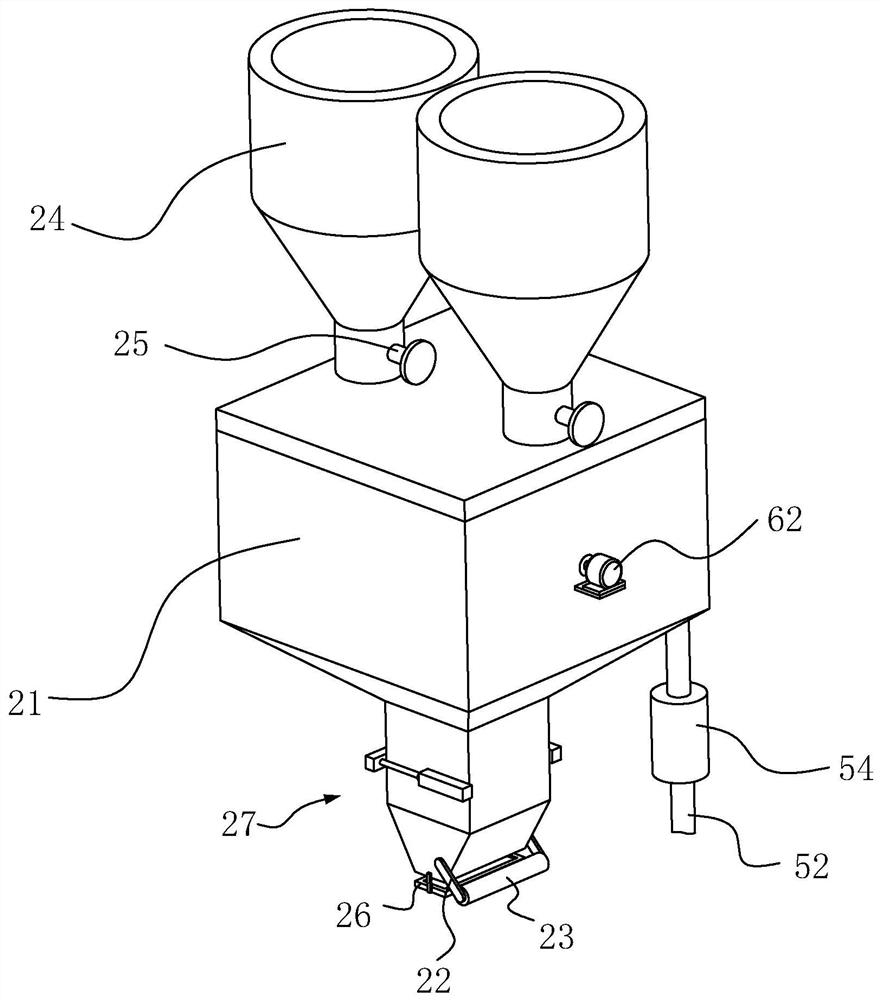

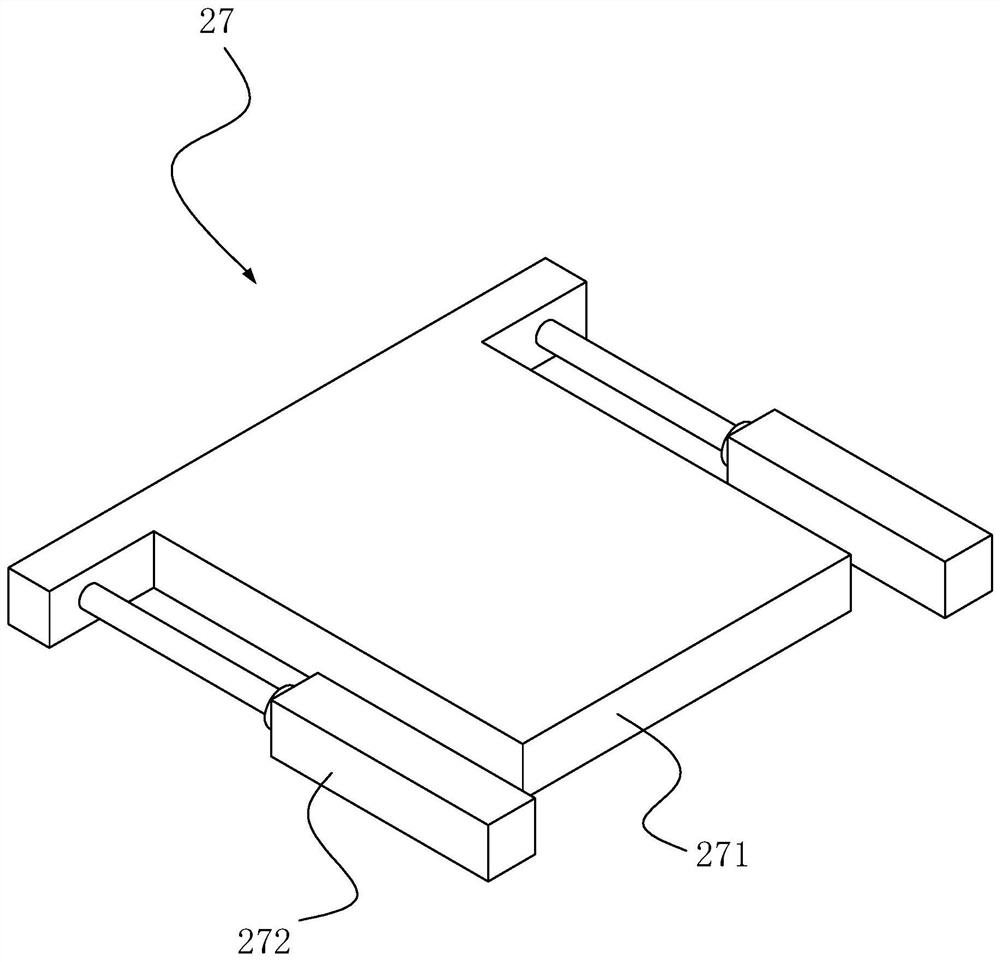

[0036] An intelligent construction machine for retaining walls in geotechnical engineering, referring to figure 1 and figure 2, including guide rail 1, frame 2, traveling mechanism 3 and lifting drive mechanism 4. A mud hopper 21 is arranged on the frame 2, and a connecting frame 22 is fixed on both sides of the discharge port of the mud hopper 21, and the connecting frame 21 is provided with a material roller 23 which is rotatably connected with the connecting frame 22 around a horizontal line. The discharge port of the mud hopper 21 is provided with a discharge control assembly 27 for controlling the discharge of the mud. A vibrating screen 26 is arranged below the discharge port. When using the retaining wall intelligent construction machine for geotechnical engineering, the guide rail 1 is arranged along the length direction of the retaining wall layi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com