Dual-power conversion mechanism and power supply power having dual-power conversion mechanism

A dual power conversion and common power supply technology, applied in circuits, electrical switches, electrical components, etc., can solve the problems of lack of mechanical self-locking devices and safety hazards in common power supplies and backup power supplies, and achieve the effect of fast action and improved switching speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

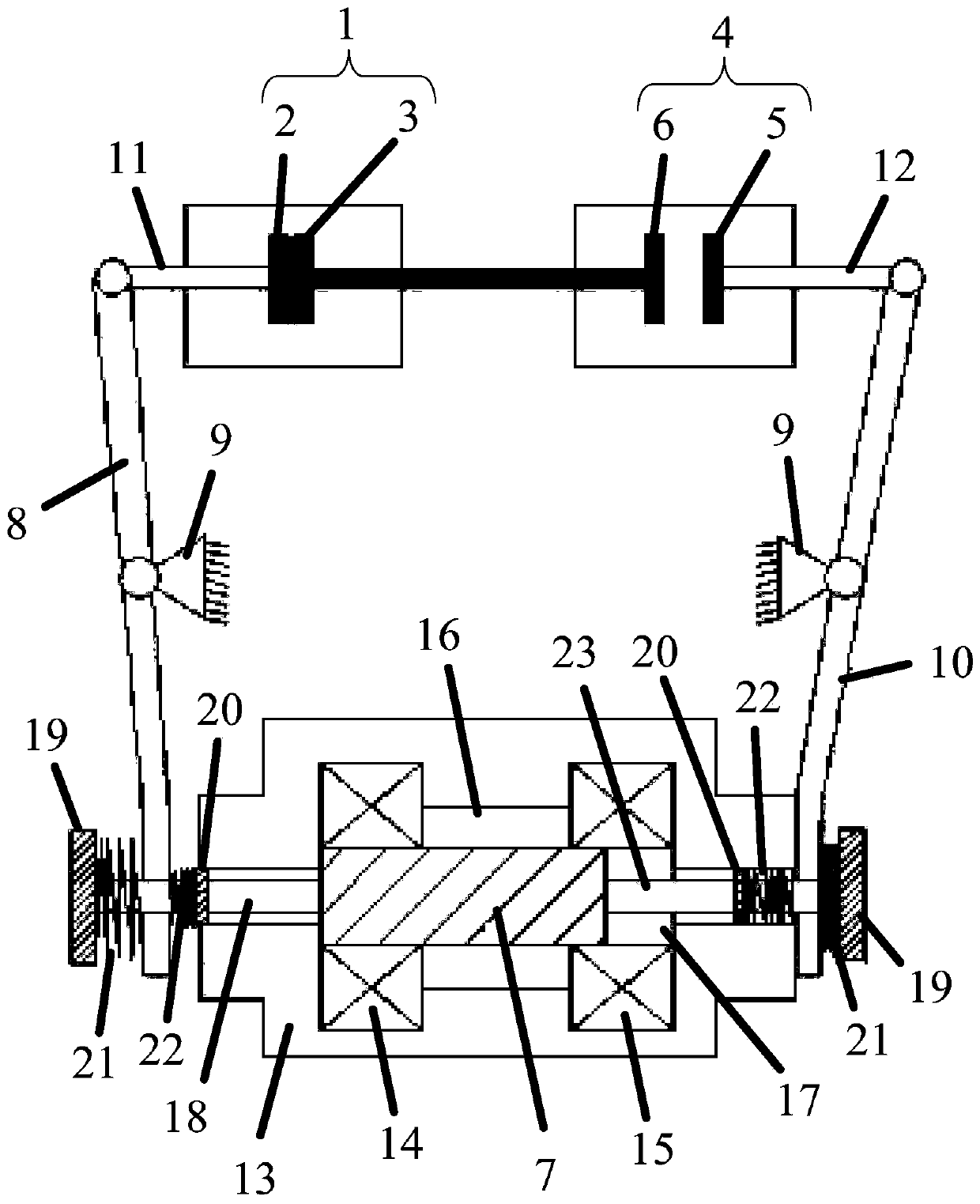

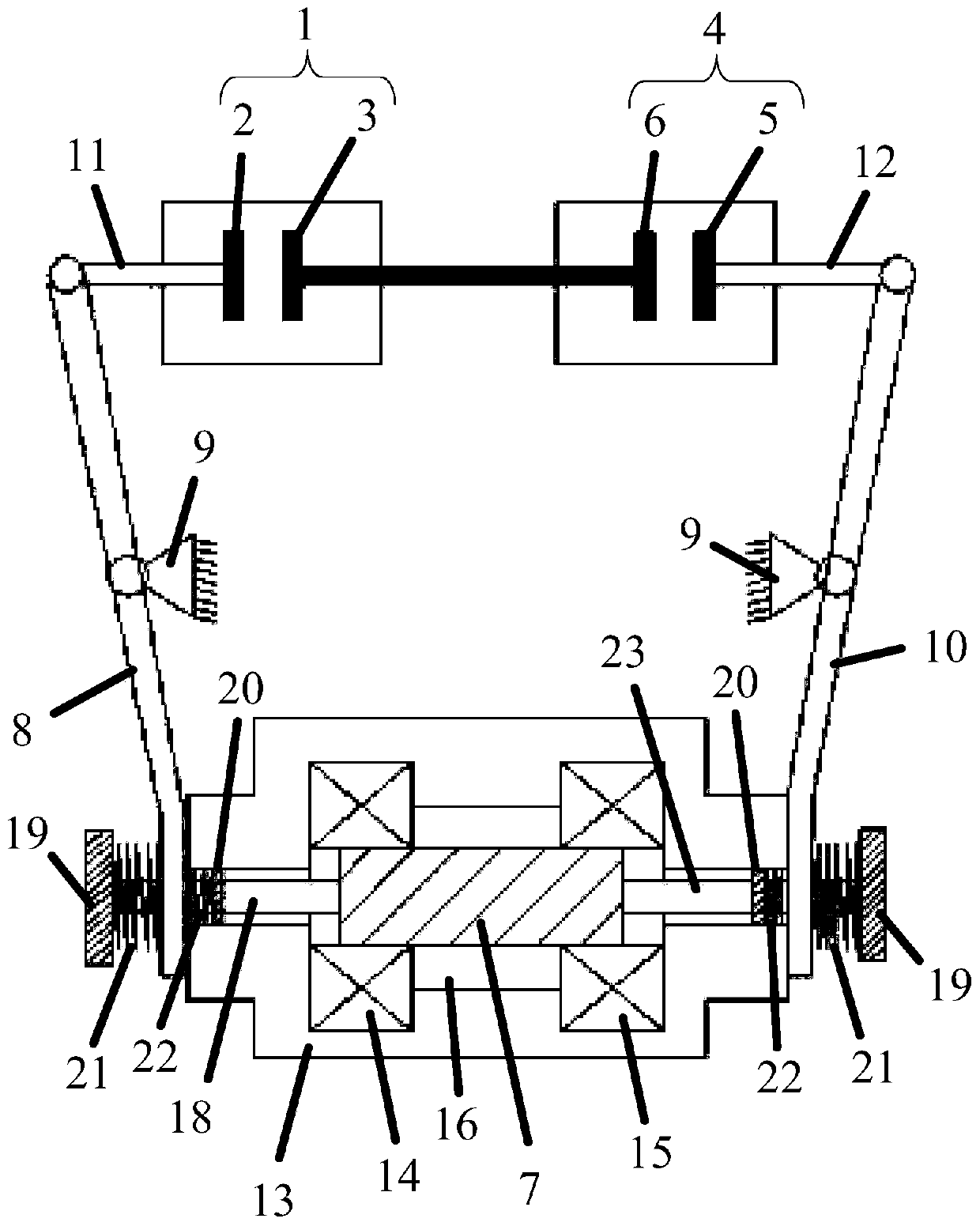

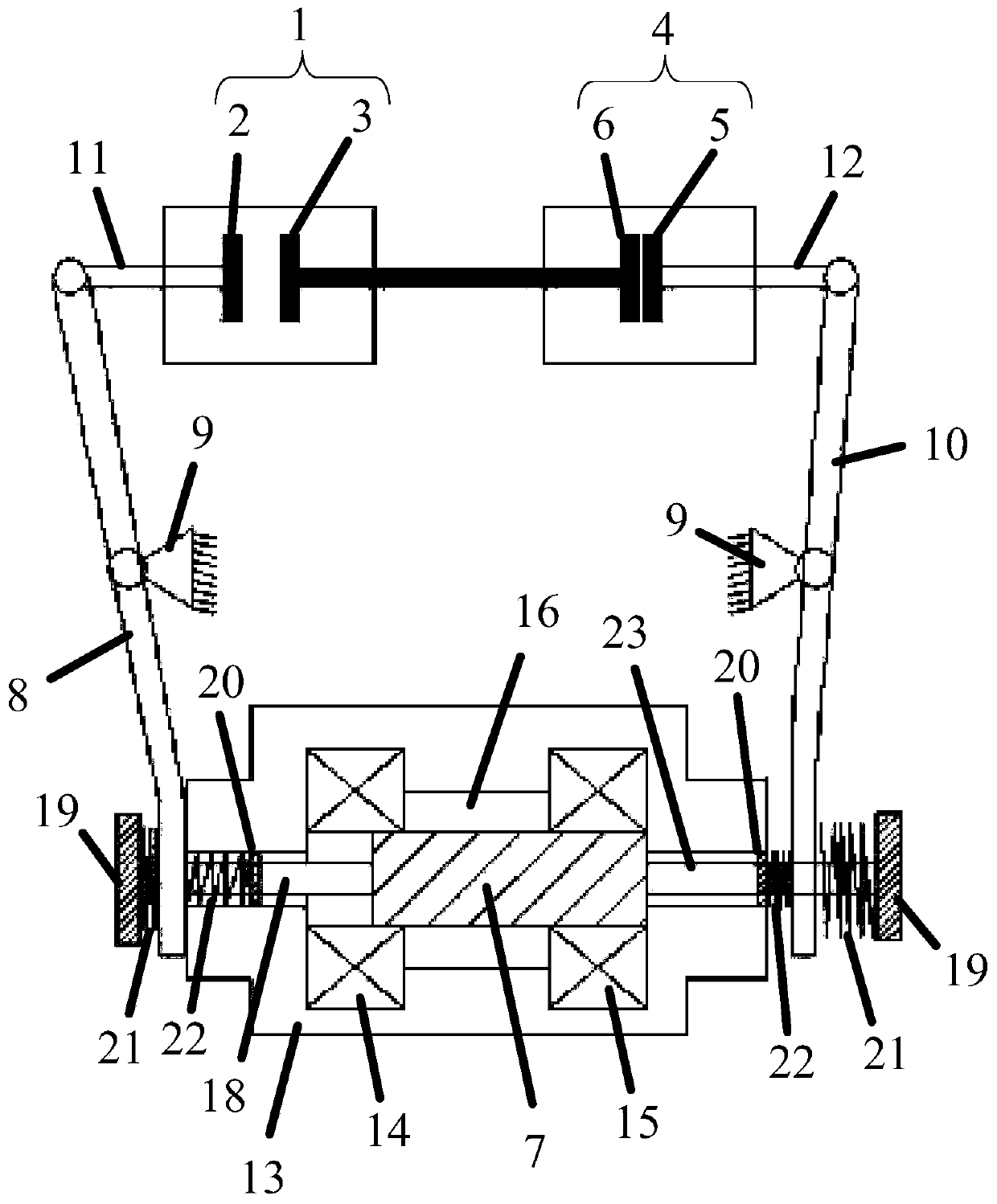

[0040] This embodiment provides a dual power conversion mechanism, such as Figure 1 to Figure 3 shown, which includes:

[0041] A commonly used power switch 1 is a vacuum tube switch, which includes a first moving contact 2 and a first static contact 3 opposite to the first moving contact 2;

[0042] The standby power switch 4 is a vacuum tube switch, which includes a second moving contact 5 and a second static contact 6 opposite to the second moving contact 5; existing power transfer switches all use air arc-extinguishing contacts , referred to as the air contact. It takes at least 10ms to extinguish the arc generated when the moving contact and the static contact are separated under air conditions; Together, a travel time of at least 20ms must be reserved for existing moving contacts. Therefore, the existing dual power supply switch cannot complete the conversion within 20ms. In this application, a vacuum tube switch is used to replace the existing air arc-extinguishing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com