Paint film automatic regulation and control system based on cascade regulation

A control system, cascade control technology, applied in control/regulation system, non-electric variable control, control of multiple variables at the same time, etc., can solve problems such as high requirements for craftsman experience and energy, and inability to take into account multiple machines at the same time. , to achieve the effect of fine control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

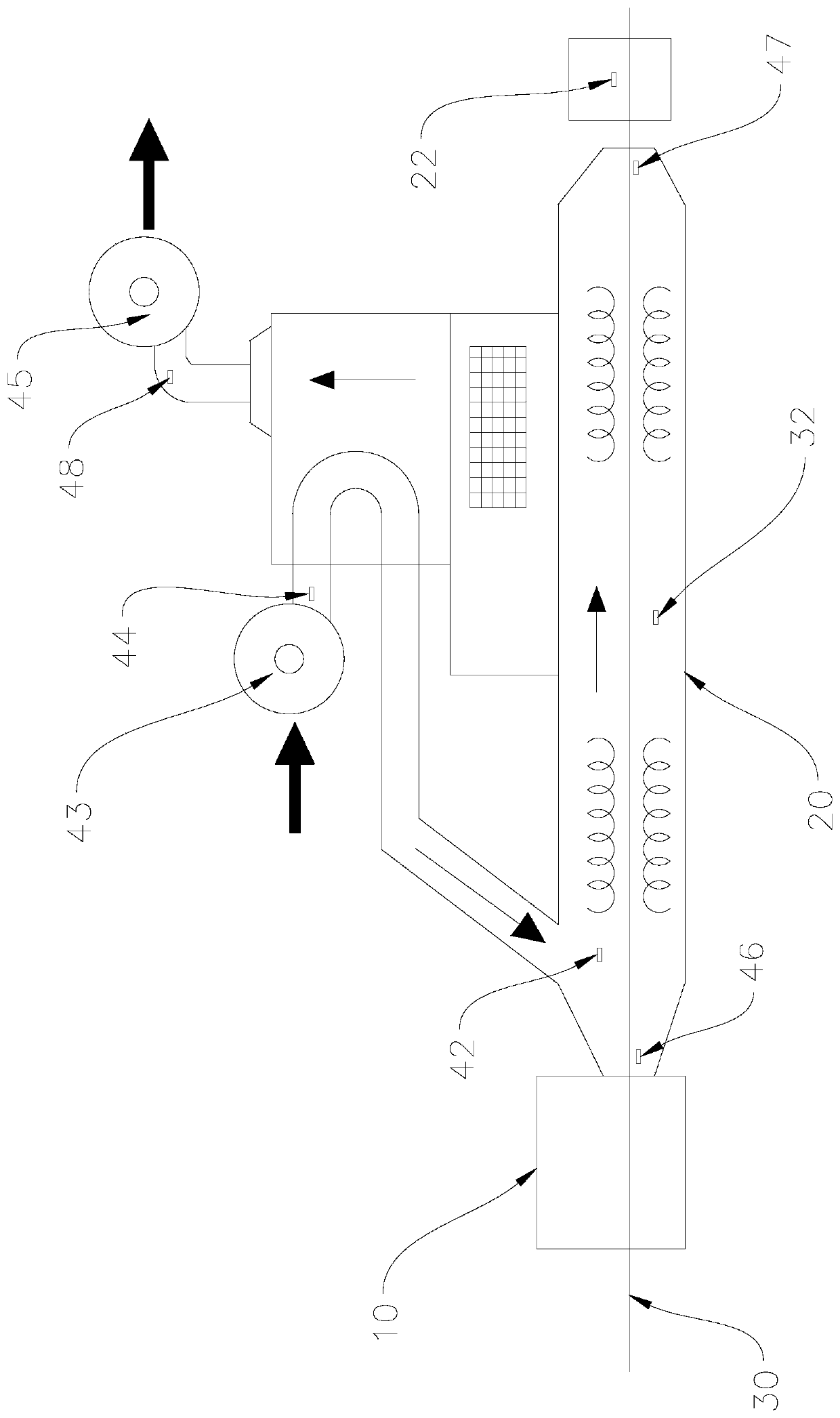

[0031] Such as figure 1 As shown, the present invention is based on the paint film automatic control system of cascade adjustment and is applied in the enamelling machine equipment, and the enamelling machine equipment comprises the paint area 10 and the oven 20, and the wire 30 enters by the paint area 10, and from the oven 20 Exit through. During this process, the wire 30 is painted in the painting zone 10 , and then dried in the oven 20 after painting. The paint film automatic control system based on the cascade regulation controls the working modules in the painting area 10 and the oven 20 to ensure that the process parameters of the wire 30 being painted are at a stable value.

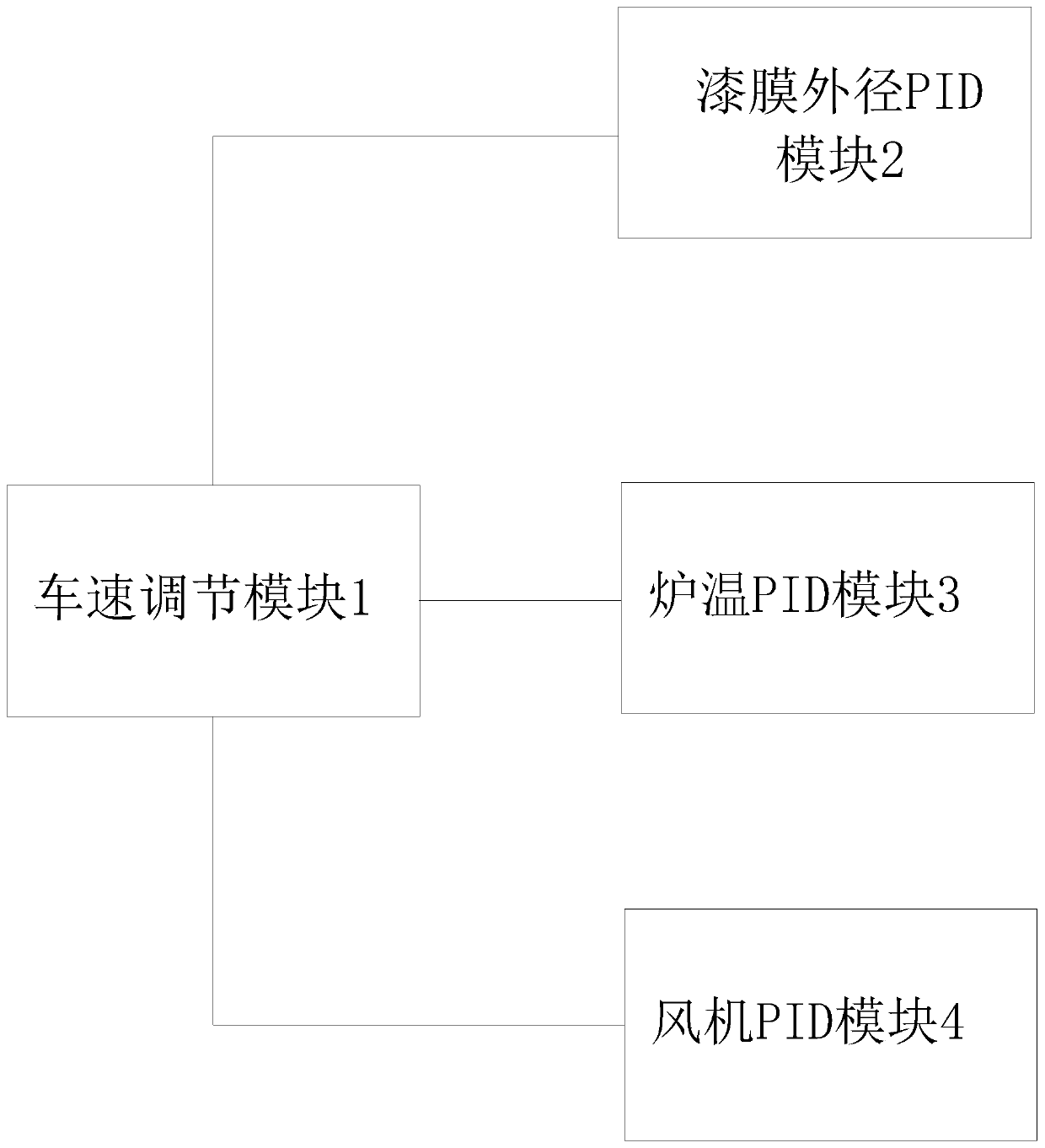

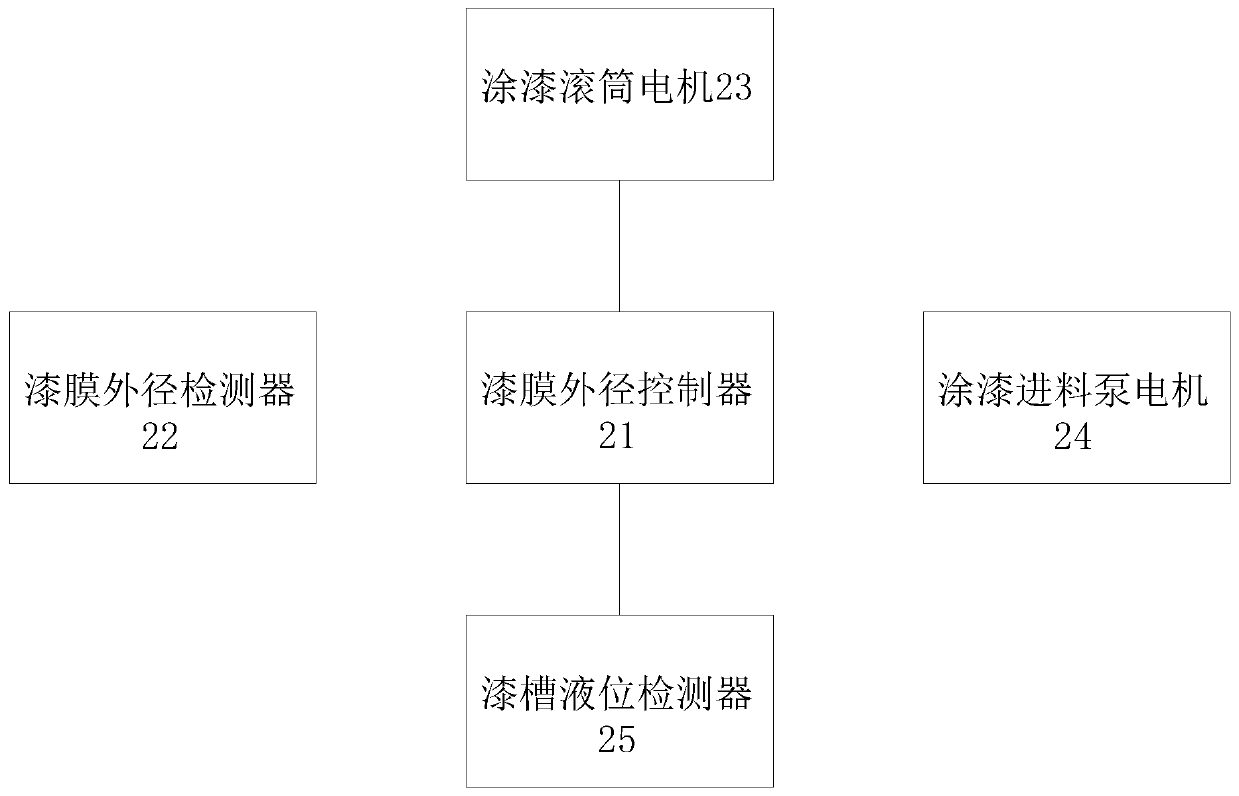

[0032] see figure 2 , the paint film automatic control system based on cascade adjustment provided by the present invention comprises a vehicle speed adjustment module 1, a paint film outer diameter PID module 2, a furnace temperature PID module 3 and a fan PID module 4, a paint film outer diam...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap