Micro-nano treatment method of fibrous clay

A processing method, micro-nano technology, applied in chemical instruments and methods, nanotechnology, nanotechnology, etc., can solve problems such as weakening of secondary agglomeration, and achieve the effects of high product quality, elimination of secondary agglomeration, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

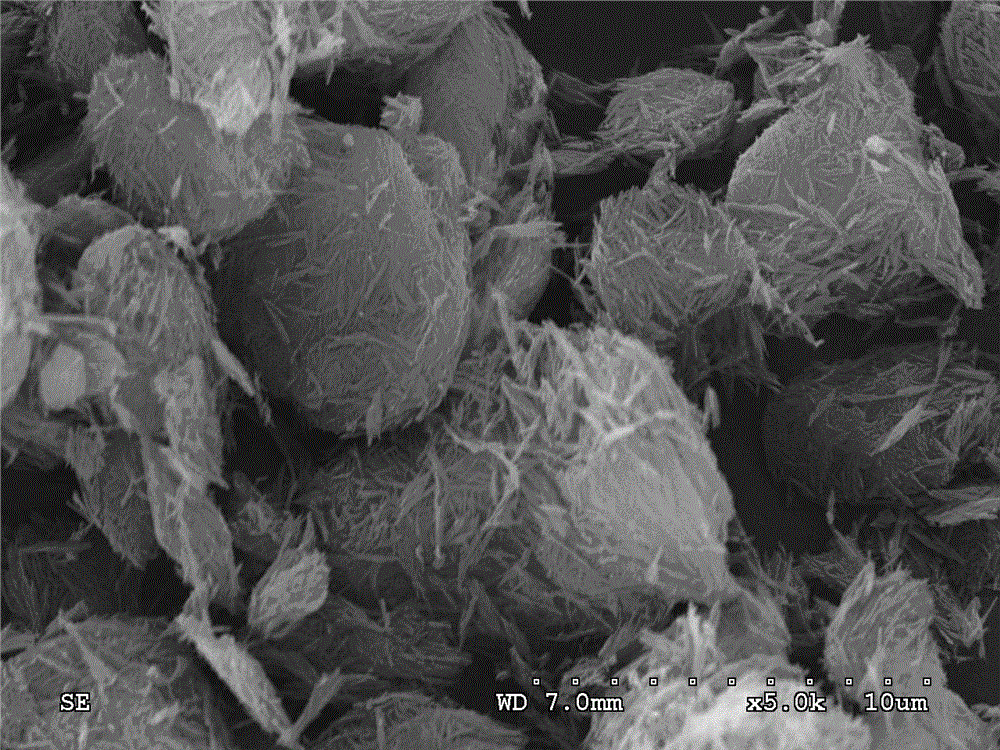

[0018] Embodiment 1: process attapulgite clay according to the following steps

[0019] (1) Clay pretreatment: mix attapulgite clay with ammonium bicarbonate, add solvent water, and squeeze the rollers three times; ammonium bicarbonate is 20% of the mass of attapulgite clay, and water is the mass of attapulgite clay 1 times;

[0020] (2) High-pressure expansion: Put the pretreated clay into a pressure-resistant airtight container, seal and heat to 100°C, keep it warm for 30 minutes, and quickly release it to normal pressure;

[0021] (3) Drying: The clay after high-pressure expansion treatment is spread out and dried naturally to obtain micro-nano attapulgite clay powder in a soft agglomerated state.

Embodiment 2

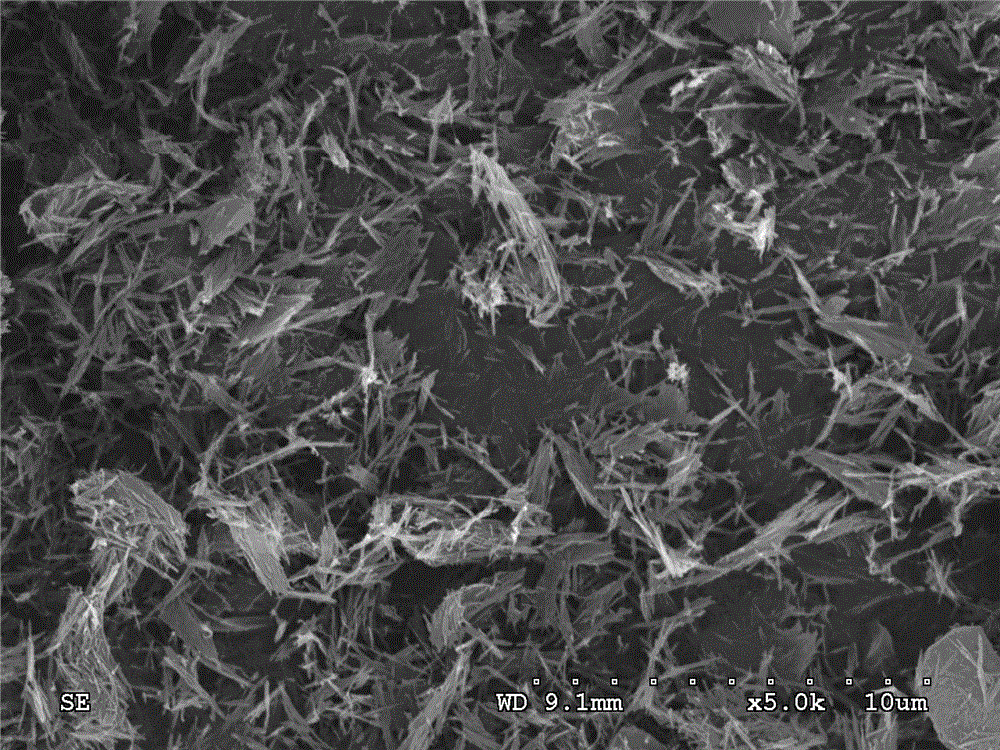

[0022] Embodiment 2: process sepiolite according to the following steps

[0023] (1) Clay pretreatment: fully mix sepiolite and ammonium chloride, then add solvent isopropanol, and squeeze the rollers 4 times; ammonium chloride is 45% of the mass of sepiolite, and isopropanol is the 1.2 times the mass of stone;

[0024] (2) High-pressure expansion: Put the pretreated sepiolite into a pressure-resistant airtight container, seal and heat to 150 °C, keep warm for 20 minutes, and quickly release to normal pressure;

[0025] (3) Drying: The sepiolite after high-pressure expansion treatment is spread out and dried naturally to obtain micro-nano sepiolite powder in a soft agglomerated state.

Embodiment 3

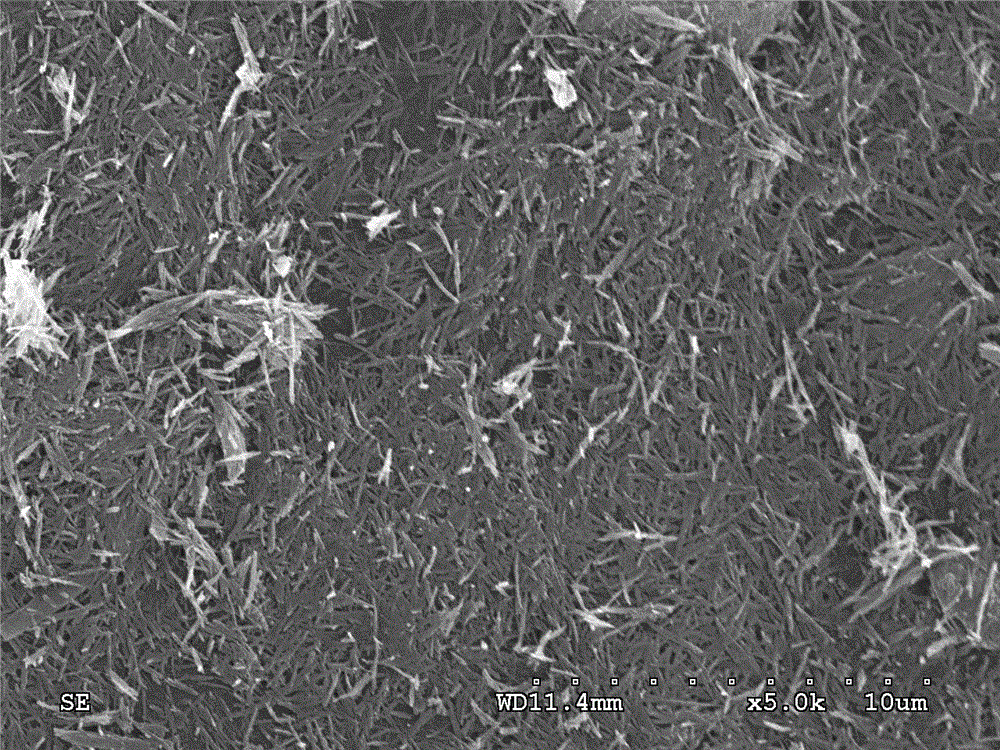

[0026] Embodiment 3: process attapulgite clay according to the following steps

[0027] (1) Clay pretreatment: Attapulgite clay is fully mixed with urea, then mixed with solvent ethanol, and squeezed 5 times on rollers; urea is 70% of the mass of attapulgite clay, and ethanol is 1.5 times the mass of attapulgite clay ;

[0028] (2) High-pressure expansion: Put the pretreated clay into a pressure-resistant airtight container, seal it and heat it to 200 °C, keep it warm for 15 minutes, and quickly release it to normal pressure;

[0029] (3) Drying: The clay after high-pressure expansion treatment is removed from the solvent at low temperature to obtain micro-nano attapulgite clay powder in a soft agglomerated state.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com