Omnidirectional beam-erecting device standing at top of pillar of house and having automatic travelling function

An all-round, column-top technology, applied in the processing of building materials, construction, building structure, etc., can solve the problems of high requirements, time-consuming disassembly and assembly, high cost, and achieve simple equipment structure, easy on-site use and installation. low difficulty effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

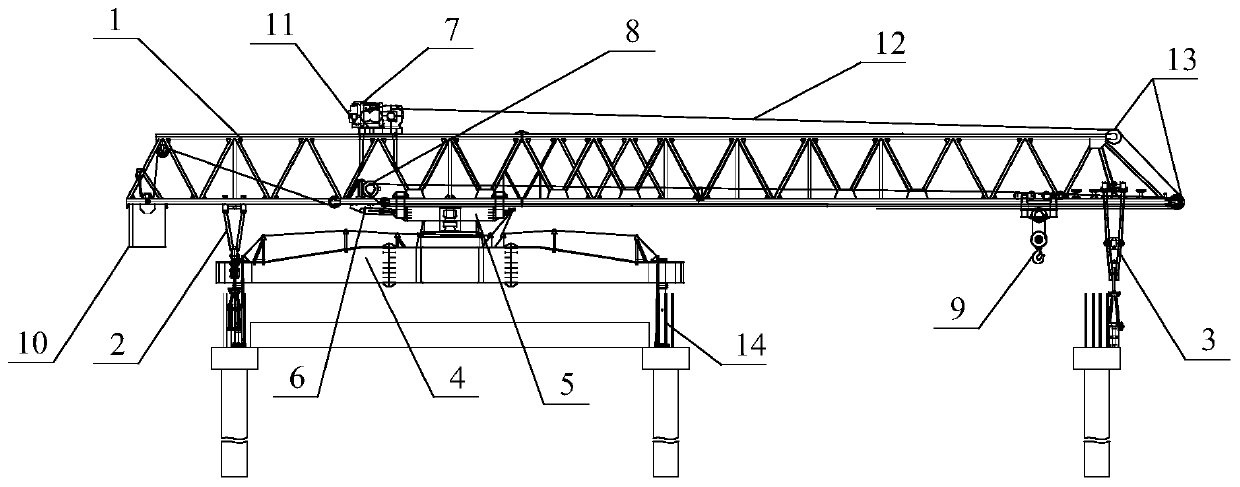

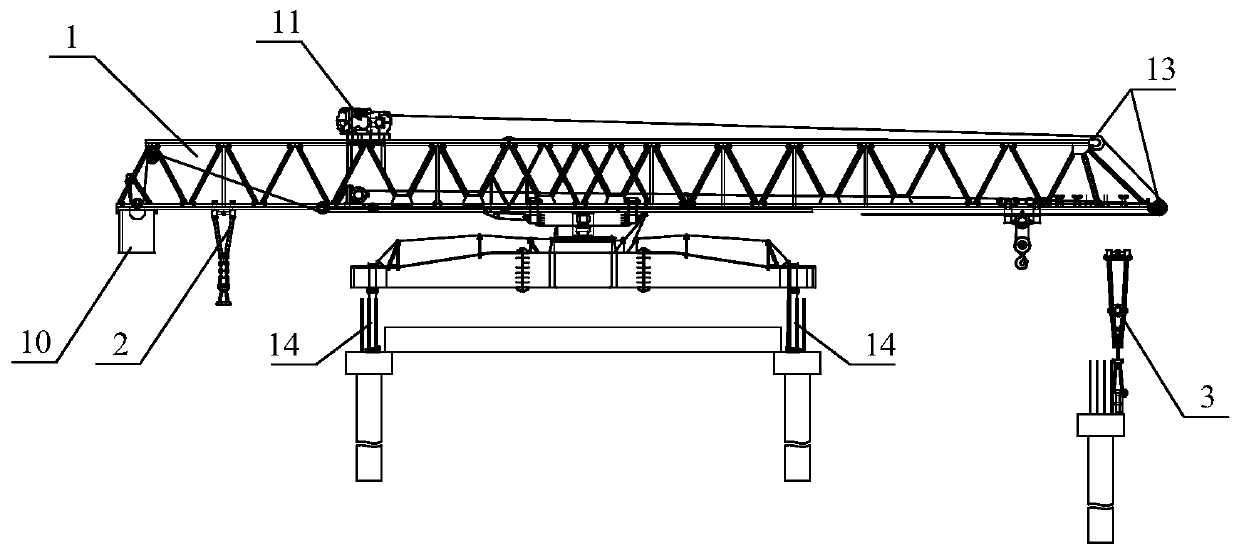

[0023] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0024] see figure 1 As shown, the embodiment of the present invention provides an all-round beam-erecting equipment standing on the top of a building column and having automatic walking function, including a main arm 1, the bottom of the main arm 1 is provided with a front leg 2 and a rear leg 3, and the front leg 2 and the rear leg 3 are arranged on the bottom of the Both the outrigger 2 and the rear outrigger 3 are provided with pad beams, a chassis 4 is arranged between the front outrigger 2 and the rear outrigger 3, and several column feet 14 are arranged on the bottom of the chassis 4 (in use, the chassis 4 and the column Pin 14 is used as middle support leg, and the quantity of column pin 14 is set according to actual needs, and in the present embodiment, the bottom of chassis 4 is provided with four column pins 14), and chassis 4 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com