Glasses wiper

A technology for glasses and bottles, which is applied in the field of wipers, can solve the problems of troublesome use, inconvenient, and inconvenient to carry, and achieve the effects of ensuring cleanliness, good sealing, and easy to carry and use when going out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

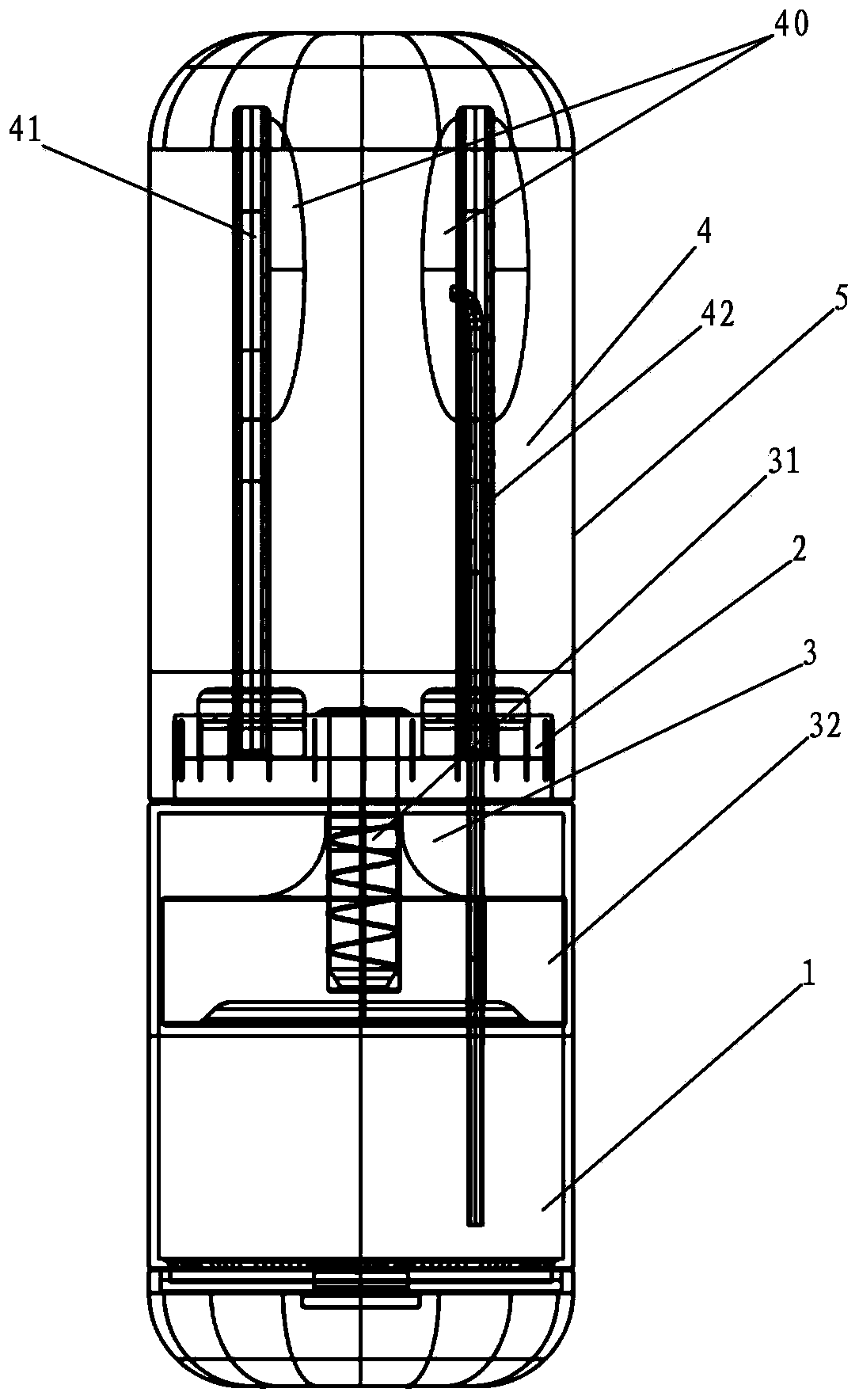

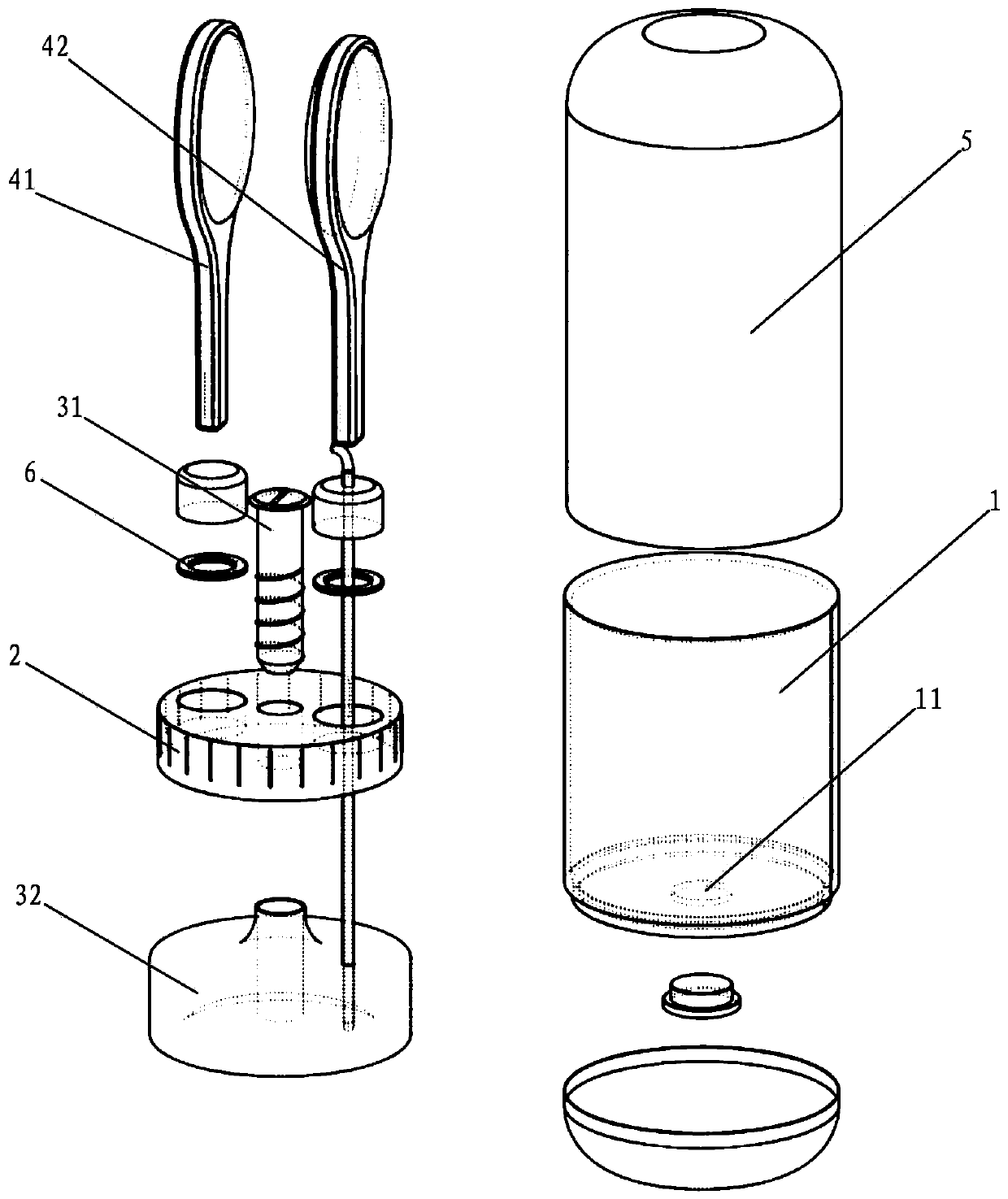

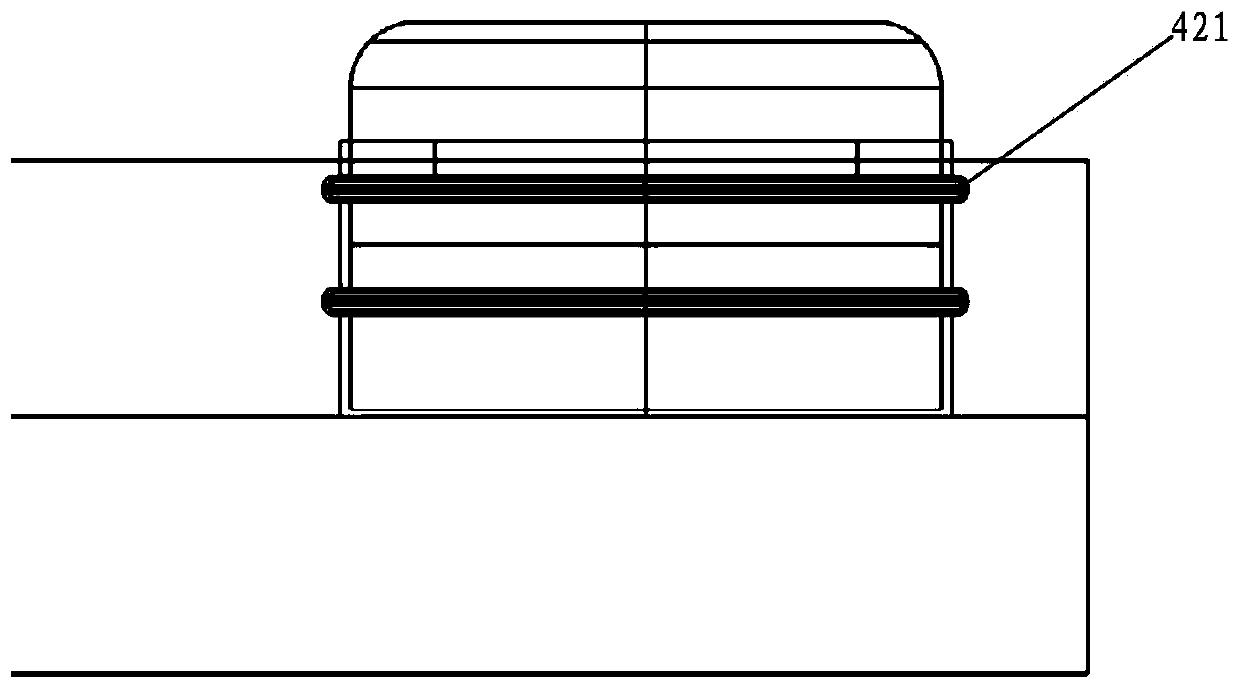

[0025] refer to figure 1 and figure 2 , the present embodiment relates to a glasses wiper, comprising a bottle body 1, a mounting block 2, an adjustment device 3, a wiping brush 4 and a cover body 5, the mounting block 2 is fixedly installed on the upper end of the bottle body 1, and the wiping brush 4 Installed on the mounting block 2, the cover body 5 can be opened or closed on the upper end of the bottle body 1; the bottle body 1 is filled with cleaning liquid, and the adjusting device 3 includes a rotating rod 31 and a pressing block 32, so The briquetting block 32 is slidably set inside the bottle body 1, and the briquetting block 32 is tightly connected with the bottle body 1; the upper surface of the bottle body 1 and the mounting block 2 has a through hole, and one end of the rotating rod 31 protrudes The through hole is rotatably mounted on the mounting block 2, and the other end of the rotating rod 31 is connected to the briquetting block 32 by screw transmission; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com