Full-meshing type triangular-prism mixing element and equipment

A mixing element and full meshing technology, applied in the mixing field, can solve the problems of difficult maintenance of glass fiber length, lack of conveying capacity, discomfort, etc., and achieve the effect of strong mixing space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

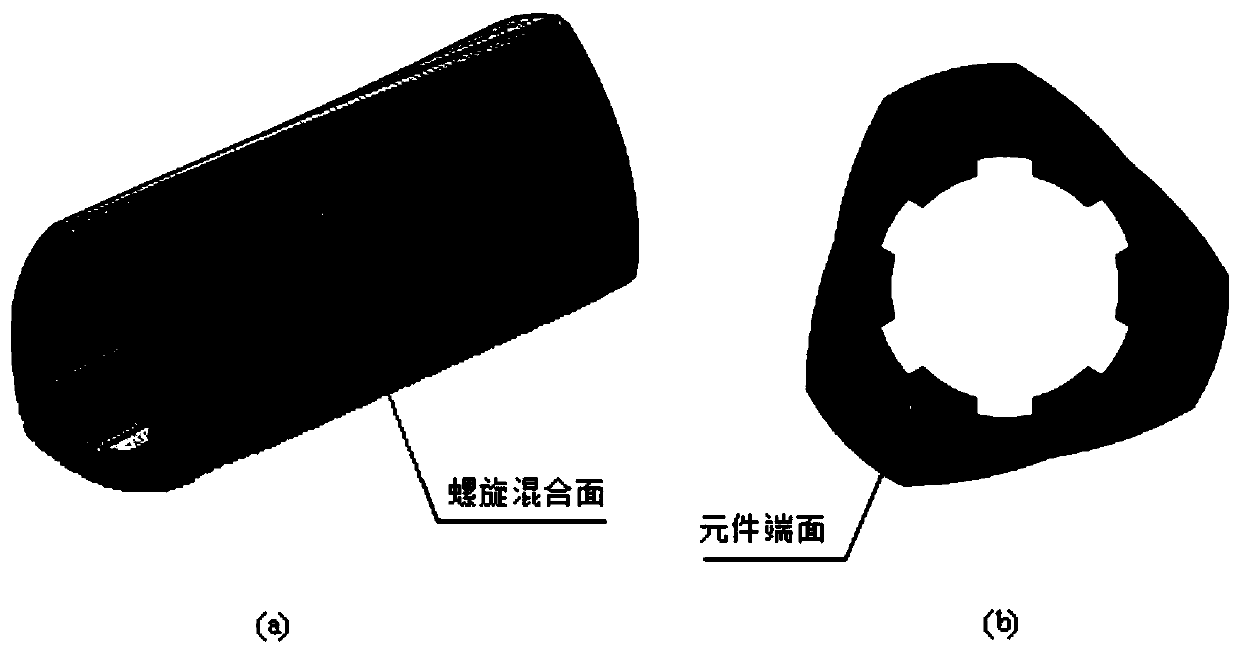

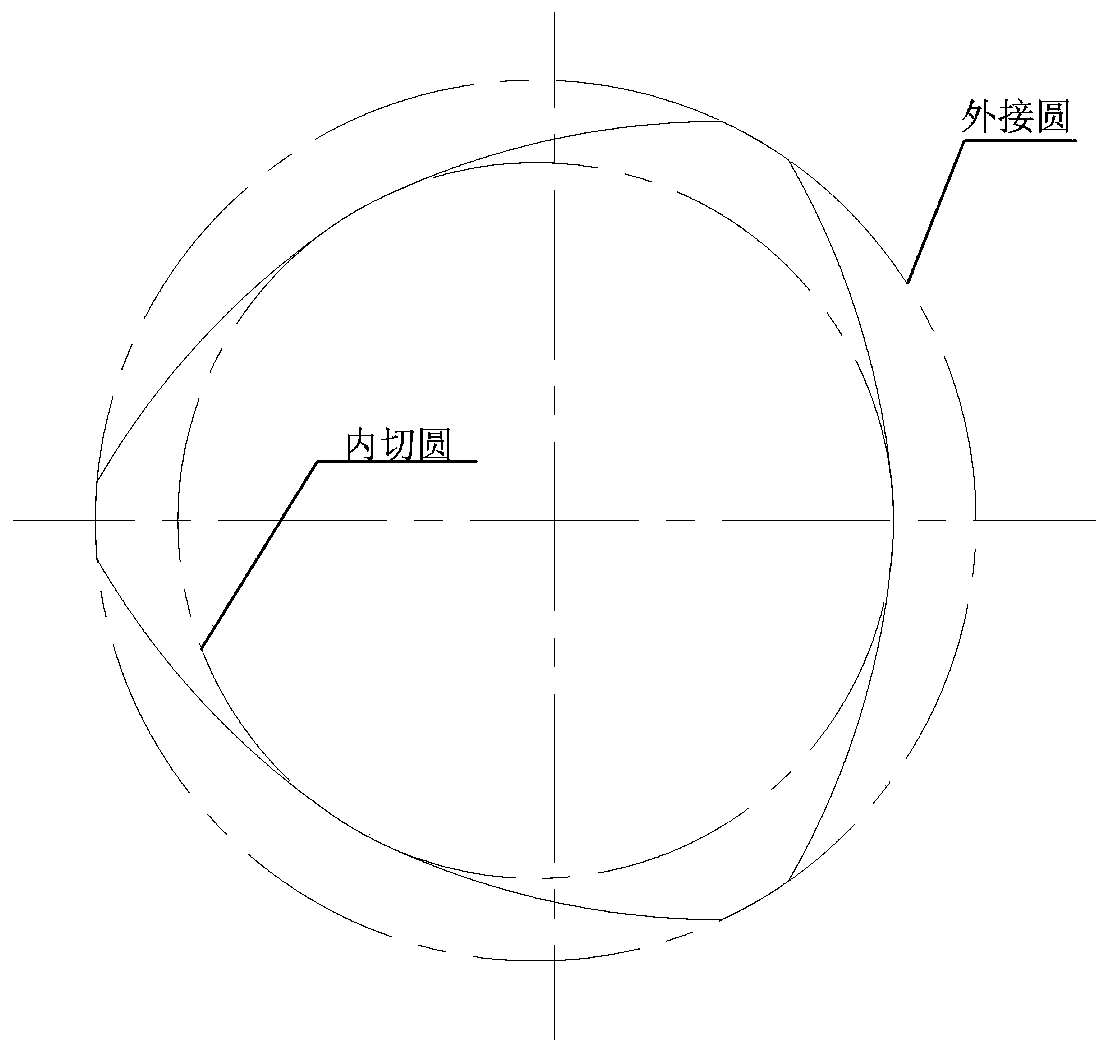

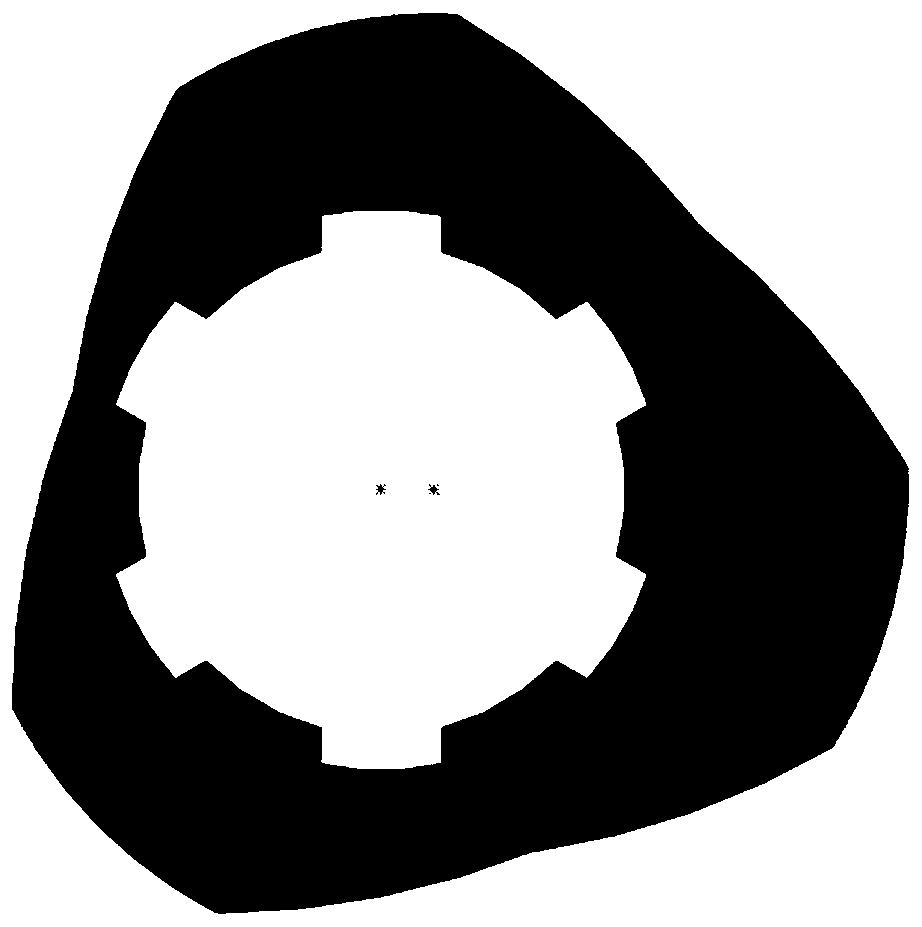

[0021] combine figure 1 , a fully meshed three-edged mixing element, the outer edges of the end faces on both sides are composed of several arcs connected. The outer wall is a spiral mixed surface structure. Each section of the spiral mixed surface structure has the same shape as the end faces on both sides but different angles, that is, the projections of the outer edges of each section on a plane perpendicular to the outer wall do not overlap, but the projection point of each section is located on the circumcircle of the section. The fully meshed three-edged mixing element can provide a stretching mixing field and at the same time have the conveying ability.

[0022] Preferably, the end faces on both sides are in a three-end engagement configuration.

[0023] Preferably, the outer edge of the section of the outer wall is composed of three arcs, and has an end face section similar to that of a three-start thread.

[0024] The center of rotation of the element is located at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com