Air-bag-clamping-type anti-theft anti-surging well lid device

A snap-in, manhole cover technology, which is applied in water conservancy projects, artificial islands, underwater structures, etc., can solve the problems of manhole cover loss, manhole cover being pushed out by water, and can not be solved well, so as to ensure stability , Improve the effect of anti-theft effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

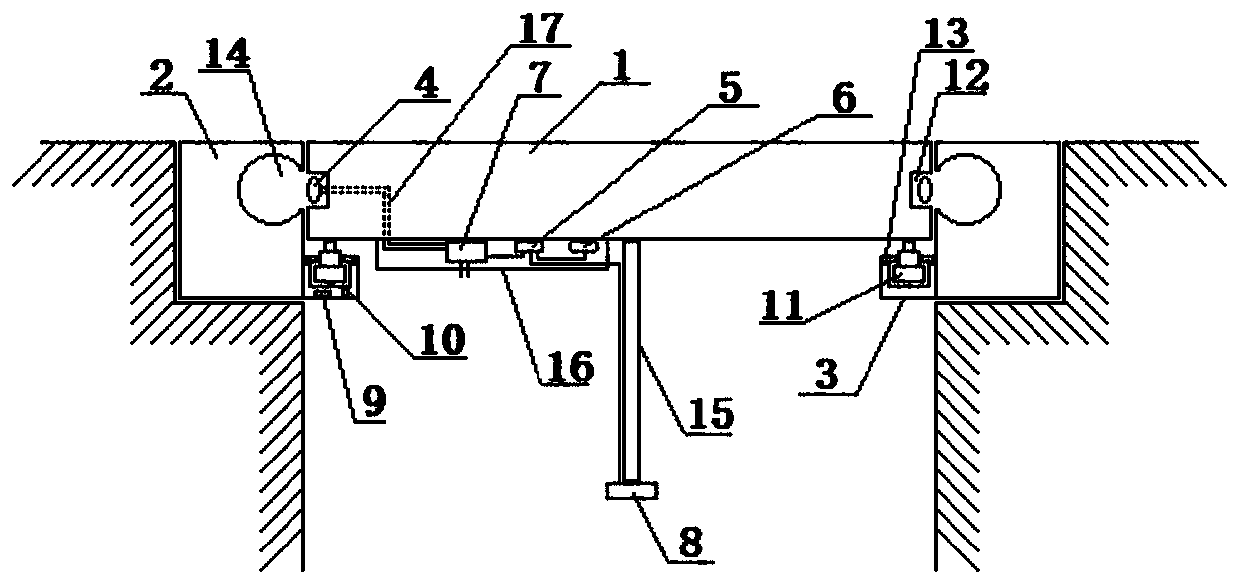

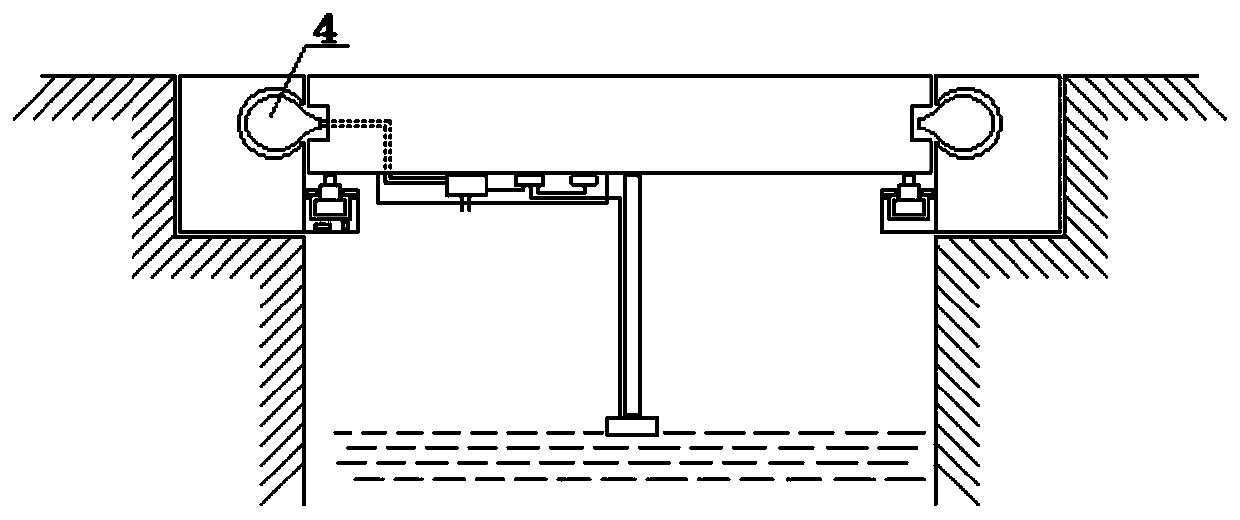

[0022] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0023] The present invention designs a kind of anti-theft and anti-surge manhole cover device of air bag locking type, such as figure 1As shown, it includes a manhole cover body 1, an outer barrel body 2, an edge barrel body 3, an air bag 4, a first control module 5, a self-contained power supply 6, a micro air pump 7, a water immersion sensor 8, a second control module 9, and a communication module 10 and at least three miniature electronically controlled telescopic rods 11; wherein, the first control module 5 is connected to the self-contained power supply 6, the miniature air pump 7, and the water immersion sensor 8 respectively, and the second control module 9 is connected to the communication module 10 and each The miniature electronically controlled expansion rod 11 is connected; Self-contained power supply 6 suppl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com