Temperature adjusting valve and heat management system with temperature adjusting valve

A temperature regulating valve and valve port technology, applied in valve operation/release devices, valve details, multi-way valves, etc. Injection process complex and other issues, to achieve the effect of simple filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

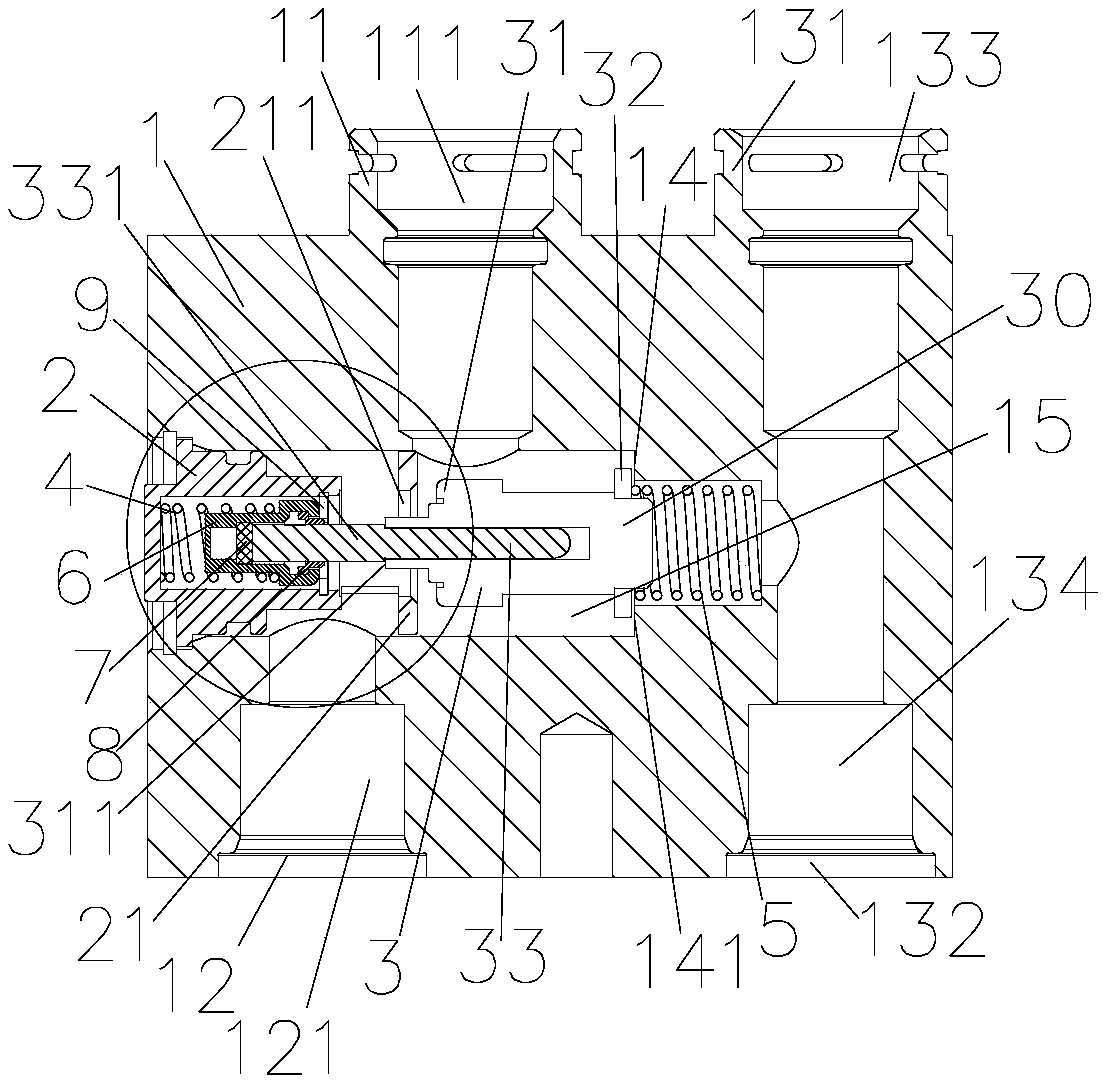

[0035] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

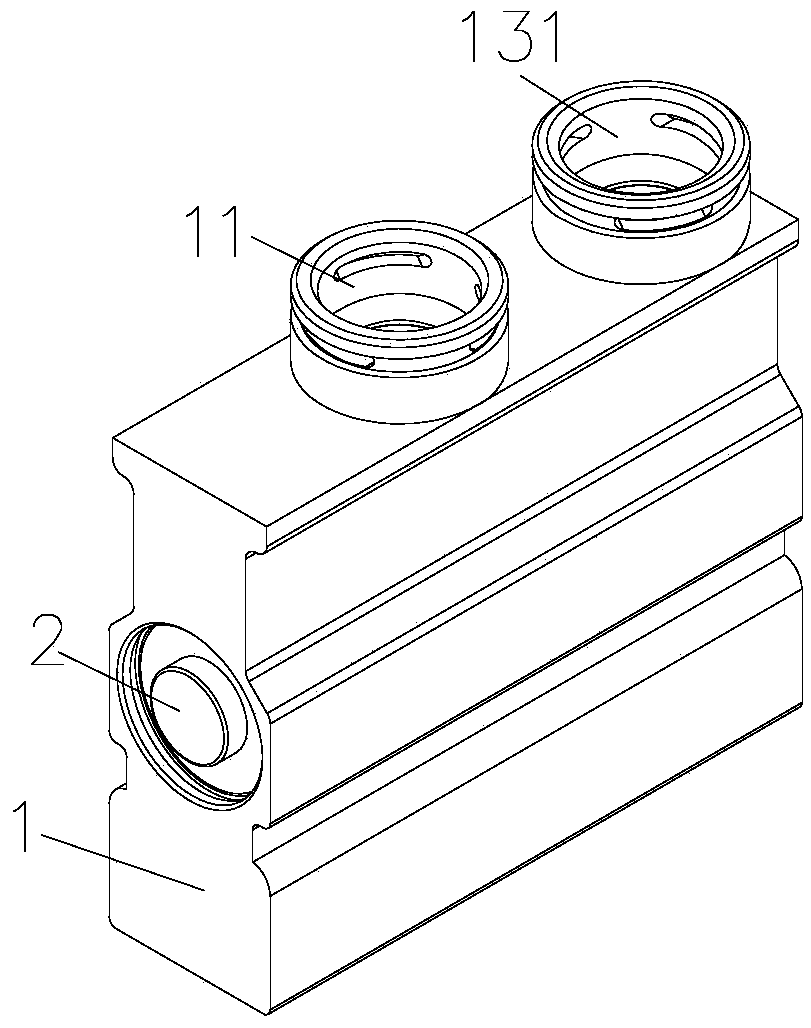

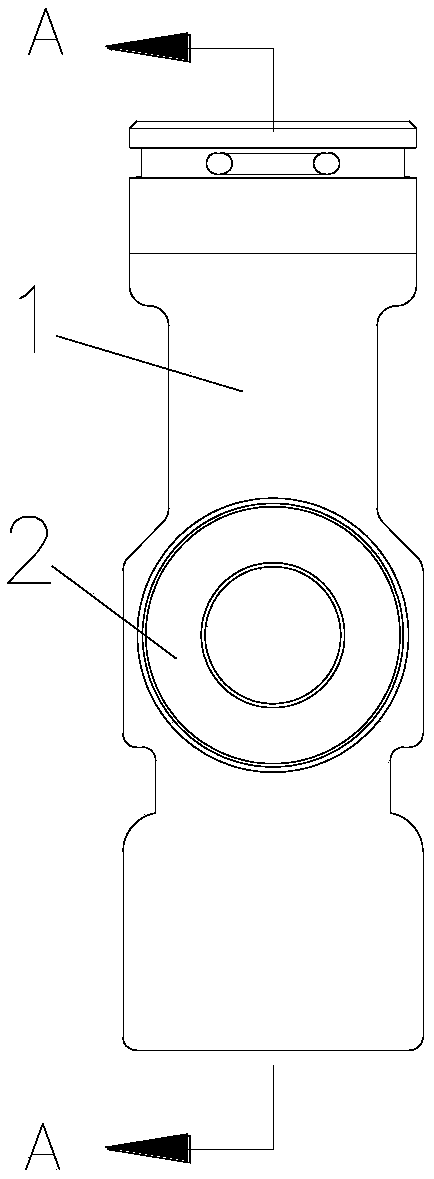

[0036] Such as Figures 1 to 3 As shown, the thermostatic valve includes a main valve body 1 , an end cover 2 , a thermal element 3 accommodated in the main valve body 1 , a second spring 4 and a first spring 5 . The main valve body 1 is provided with a first interface part 11, a second interface part 12, a third interface part 131 and a fourth interface part 132, wherein the first interface part 11 is provided with a first interface channel 111, and the second interface part 12 is provided with There is a second interface channel 121 , the third interface part 131 is provided with a third interface channel 133 , and the fourth interface part 132 is provided with a fourth interface channel 134 . The main valve body 1 is also provided with a valve body cavity 15 , and the end cover 2 is fixed to the main valve body 1 and the joint is seale...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com