Refrigerant mixing and injecting machine and refrigerant mixing and injecting method

A refrigerant and mixed injection technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of low production efficiency, high labor intensity, complicated steps, etc., and achieve easy charging, easy equipment maintenance, and reasonable design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

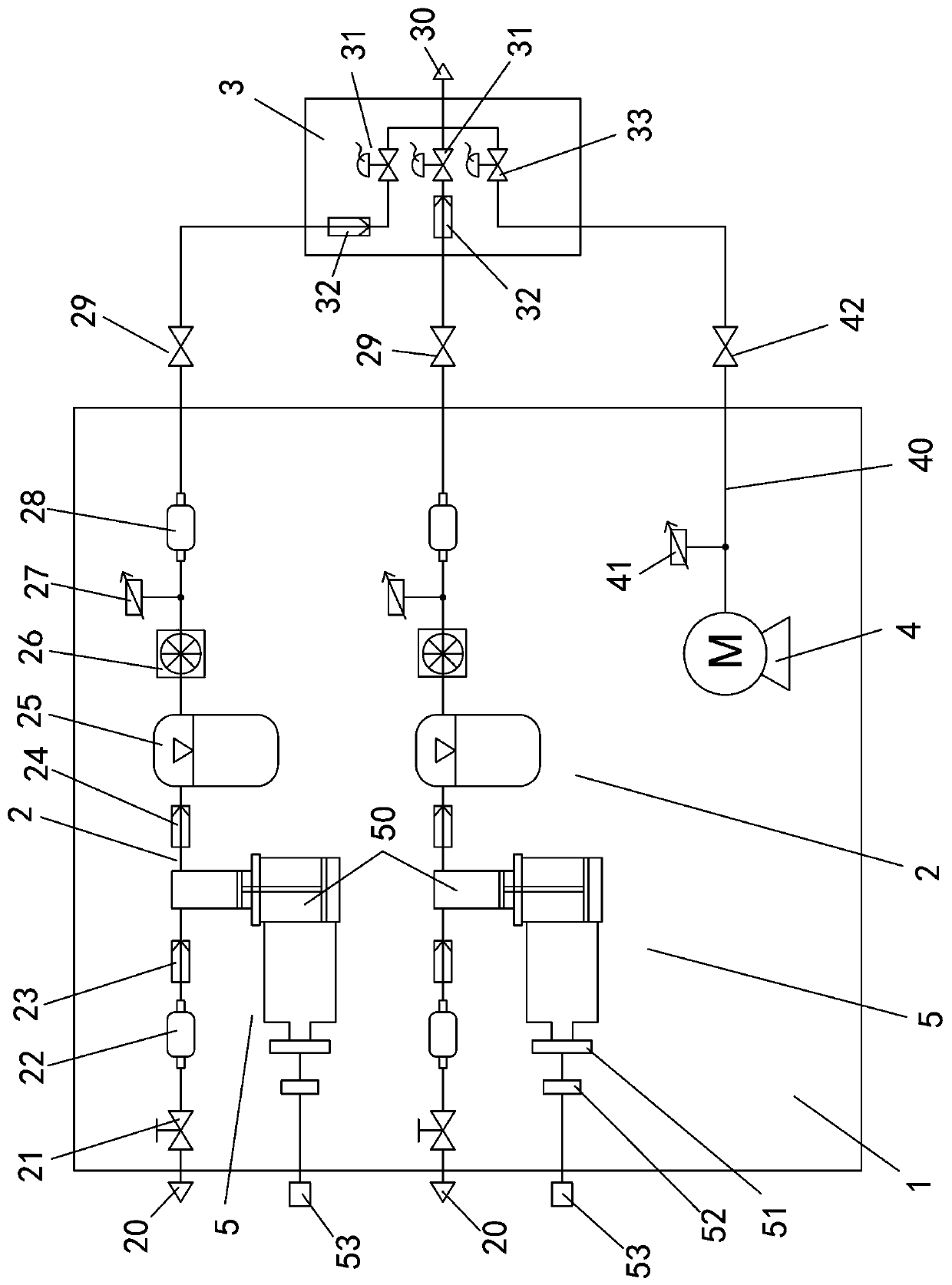

[0023] Embodiment one, see figure 1 As shown, a refrigerant mixing injection machine includes a host 1, two delivery pipes 2, a vacuum pump 4 and a flow charging valve assembly 3, the delivery pipeline 2 and the vacuum pump 4 are arranged in the host 1, and each delivery pipeline 2 ends They are the input interface 20 and the output interface 29 respectively. The input interface 20 and the output interface 29 of each delivery pipeline 2 are set on the host machine 1 , and the output interfaces 29 of the two delivery pipelines 2 are connected to the flow filling valve assembly 3 .

[0024] Wherein, each of the delivery pipelines 2 is sequentially provided with an input valve 21, an input filter 22, an input check valve 23, a pressure regulating device 5, a second check valve 24, an accumulator 25, a flow meter 26, a pressure A sensor 27 and an output filter 28 are arranged successively between the input interface 20 and the output interface 29 . The pressure regulating device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com