Refrigerating agent leakage detection method and air conditioner

A leak detection and refrigerant technology, applied in mechanical equipment and other directions, can solve problems such as misjudgment, single detection data parameter, refrigerant leakage, etc., to avoid potential safety hazards, avoid damage, and improve functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

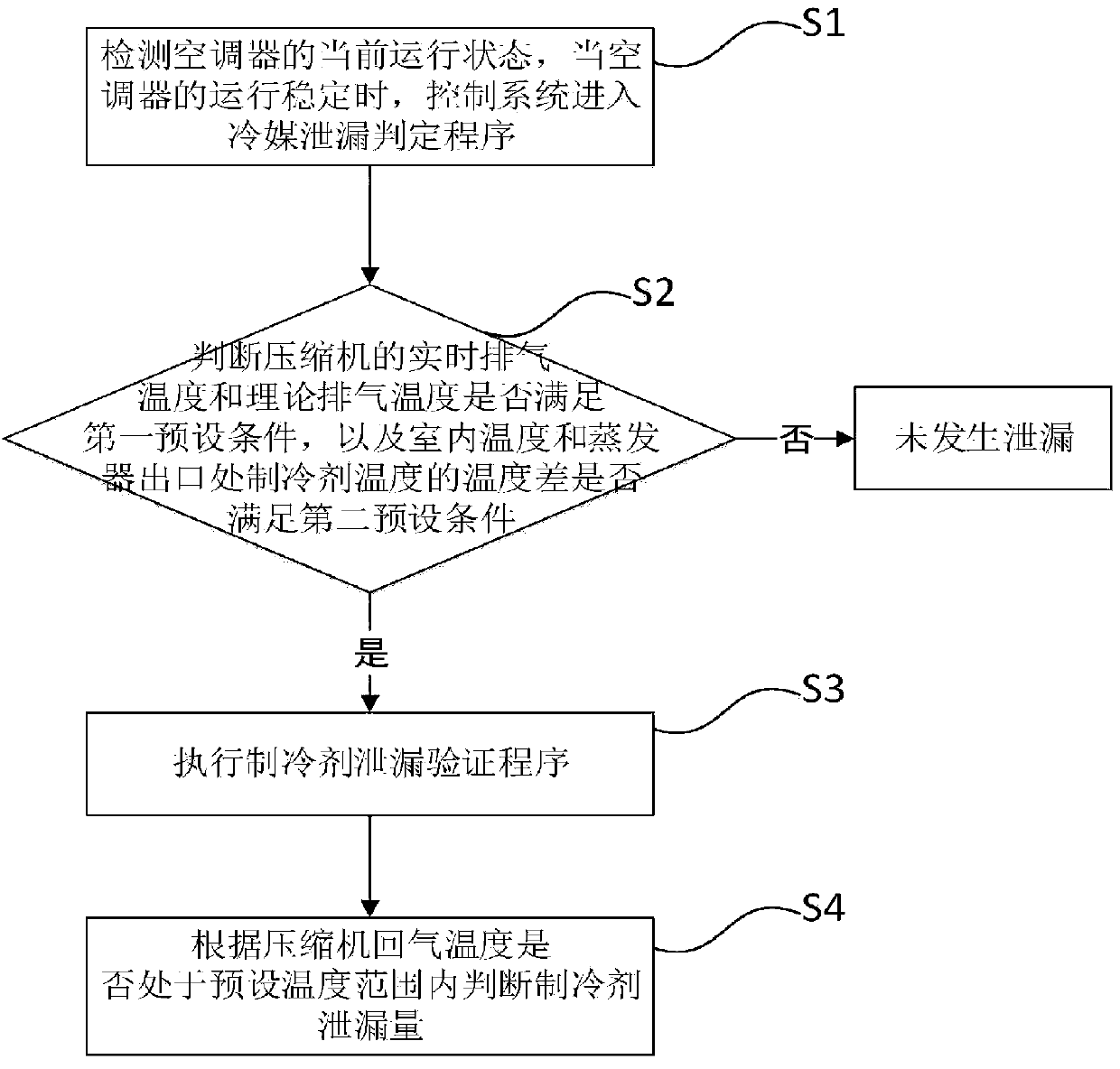

[0056] figure 1 It is a refrigerant leakage detection method according to an embodiment of the present invention, which specifically includes the following steps:

[0057] S1. Detect the current operating state of the air conditioner. When the operation of the air conditioner is stable, the control system enters the refrigerant leakage determination procedure.

[0058] Among them, there are many indicators for measuring the operating state of the air conditioner, such as the continuous operating time of the compressor, the difference between the current indoor temperature and the indoor coil temperature, and the outdoor ambient temperature. Through a combination of multiple methods, it can accurately determine whether the operating state of the air conditioner meets the requirements, and then determine whether the operation of the air conditioner is stable, and enter the refrigerant leakage determination procedure when the air conditioner is stable to ensure accurate detection.

[00...

Embodiment 2

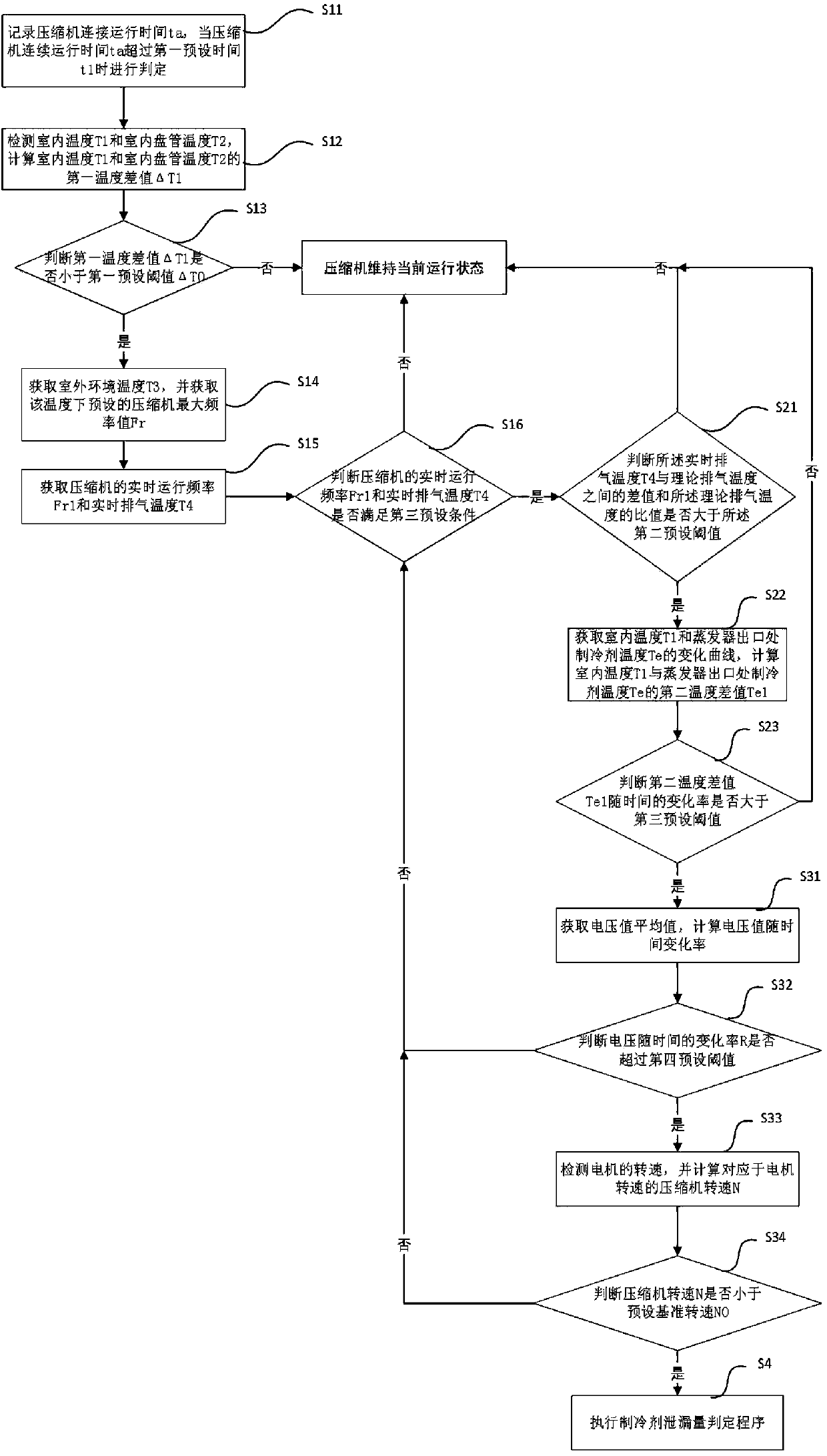

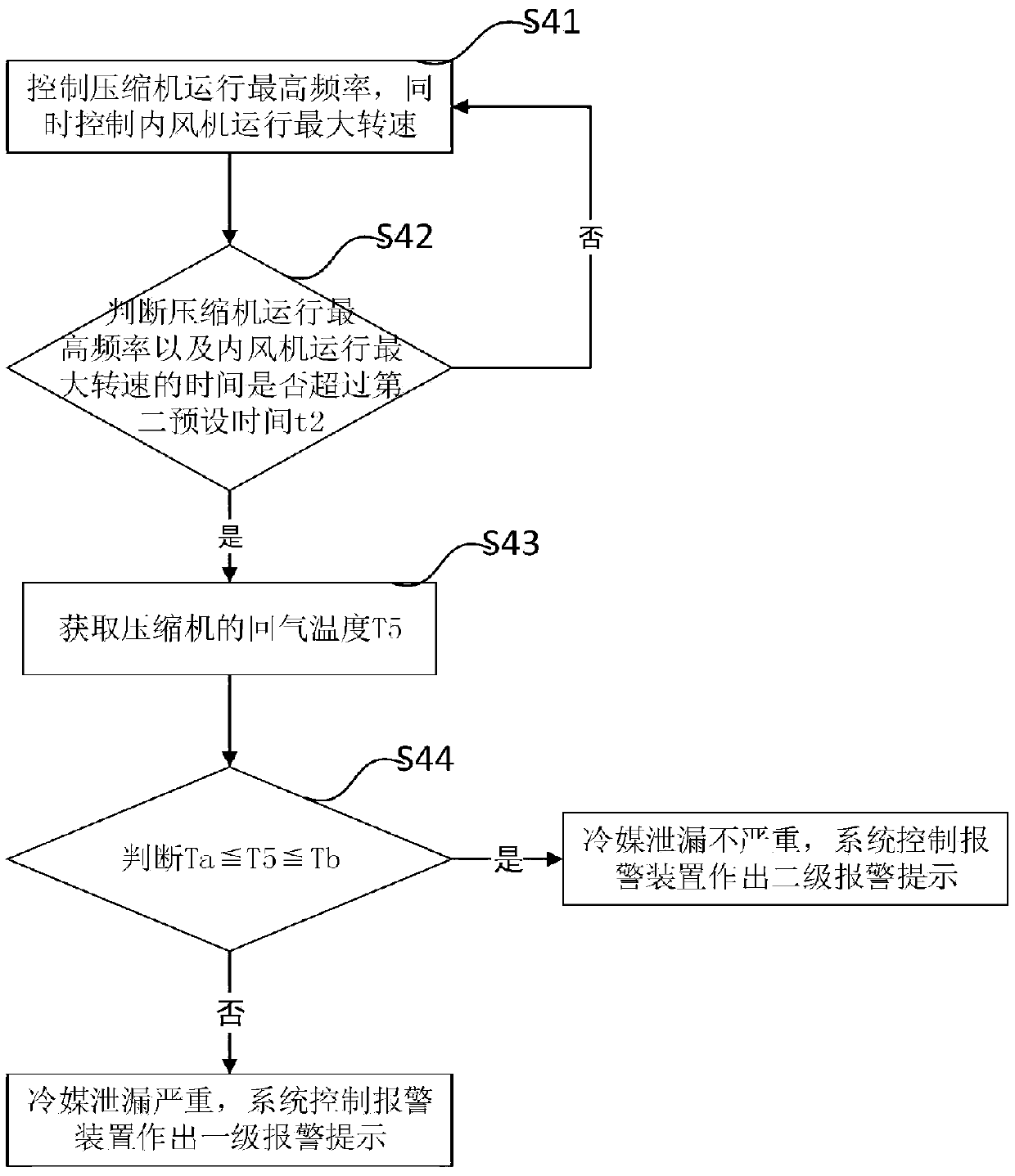

[0072] Such as Figure 2~4 As shown, this embodiment further limits the refrigerant leakage detection method on the basis of Embodiment 1, and specifically includes the following steps:

[0073] S11. After the air conditioner is turned on, the system automatically records the continuous operating time ta of the compressor, and judges whether the continuous operating time ta of the compressor reaches the first preset time t1, when the continuous operating time ta of the compressor reaches the first preset time t1 , Go to step S12.

[0074] Specifically, immediately after the air conditioner is turned on, the air conditioner has not adjusted the indoor ambient temperature. The difference between the indoor ambient temperature and the user-set target temperature is large. The compressor runs at a higher frequency. In order to quickly adjust the indoor temperature, the expansion valve The opening degree is larger. After the compressor's continuous running time reaches the first preset...

Embodiment 3

[0125] On the basis of Embodiments 1 and 2, this embodiment also provides an air conditioner. The air conditioner adopts the refrigerant leakage detection method described in the above embodiment. Specifically, the air conditioner includes a compressor and an evaporator. , Refrigerant circulation pipeline, detection system, timing module and control system; the detection system and timing module are connected with the control system, and one end of the refrigerant circulation pipeline system is connected with the compressor and the other end is connected with the evaporator. The detection system includes a temperature detection system and a rotation speed detector, and the temperature detection system includes:

[0126] The first temperature sensor is arranged at the air inlet of the indoor unit to detect the indoor temperature;

[0127] The second temperature sensor is arranged on the indoor unit evaporator coil for detecting the temperature of the indoor coil;

[0128] The third t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com