Rockwell hardness tester with function of adjusting angle of measuring platform

A technology of Rockwell hardness tester and measuring platform, which is applied in the direction of testing material hardness, measuring device, strength characteristics, etc., can solve problems such as hardness measurement data distortion, cracking, and indenter damage, and achieve the effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

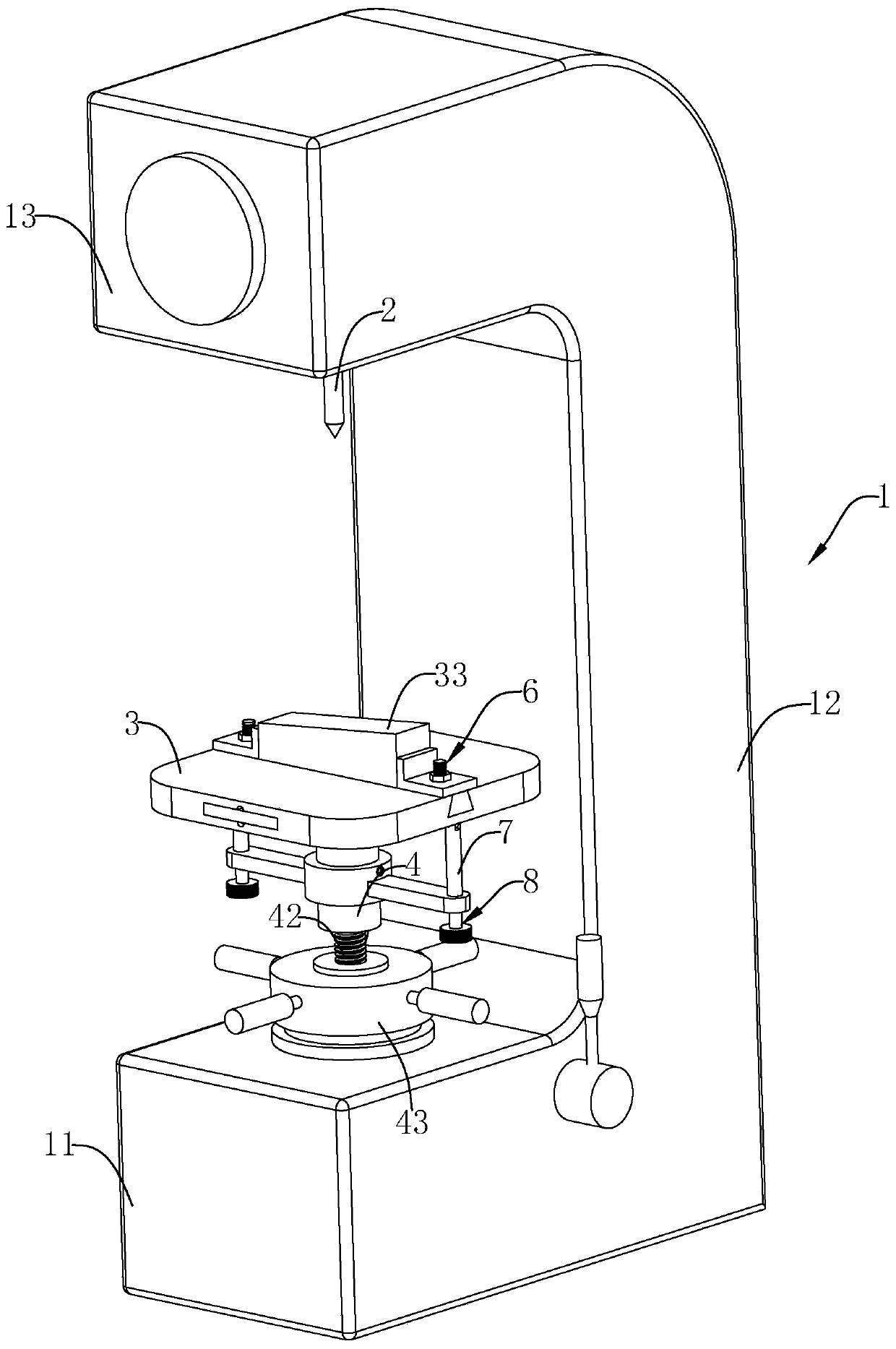

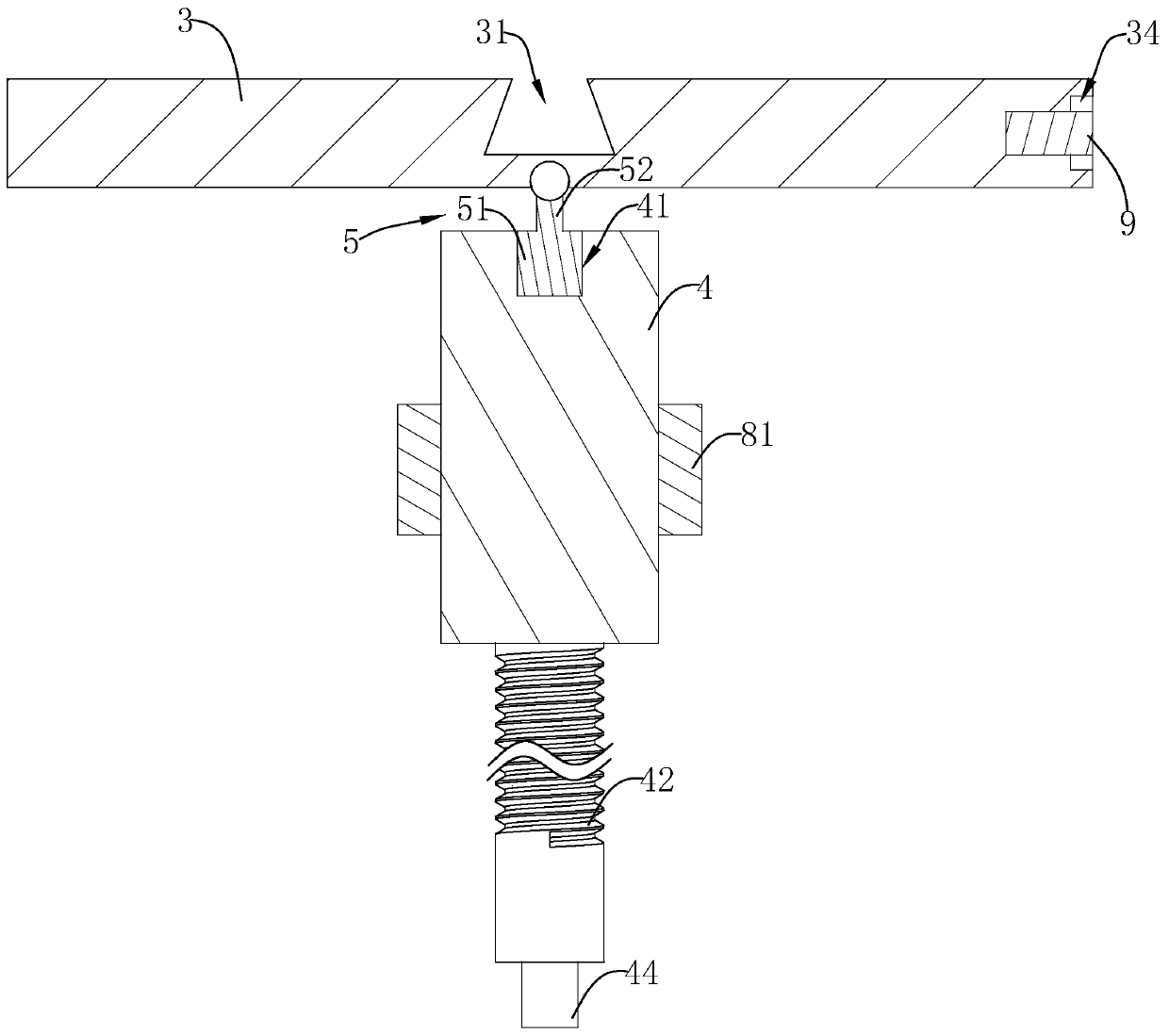

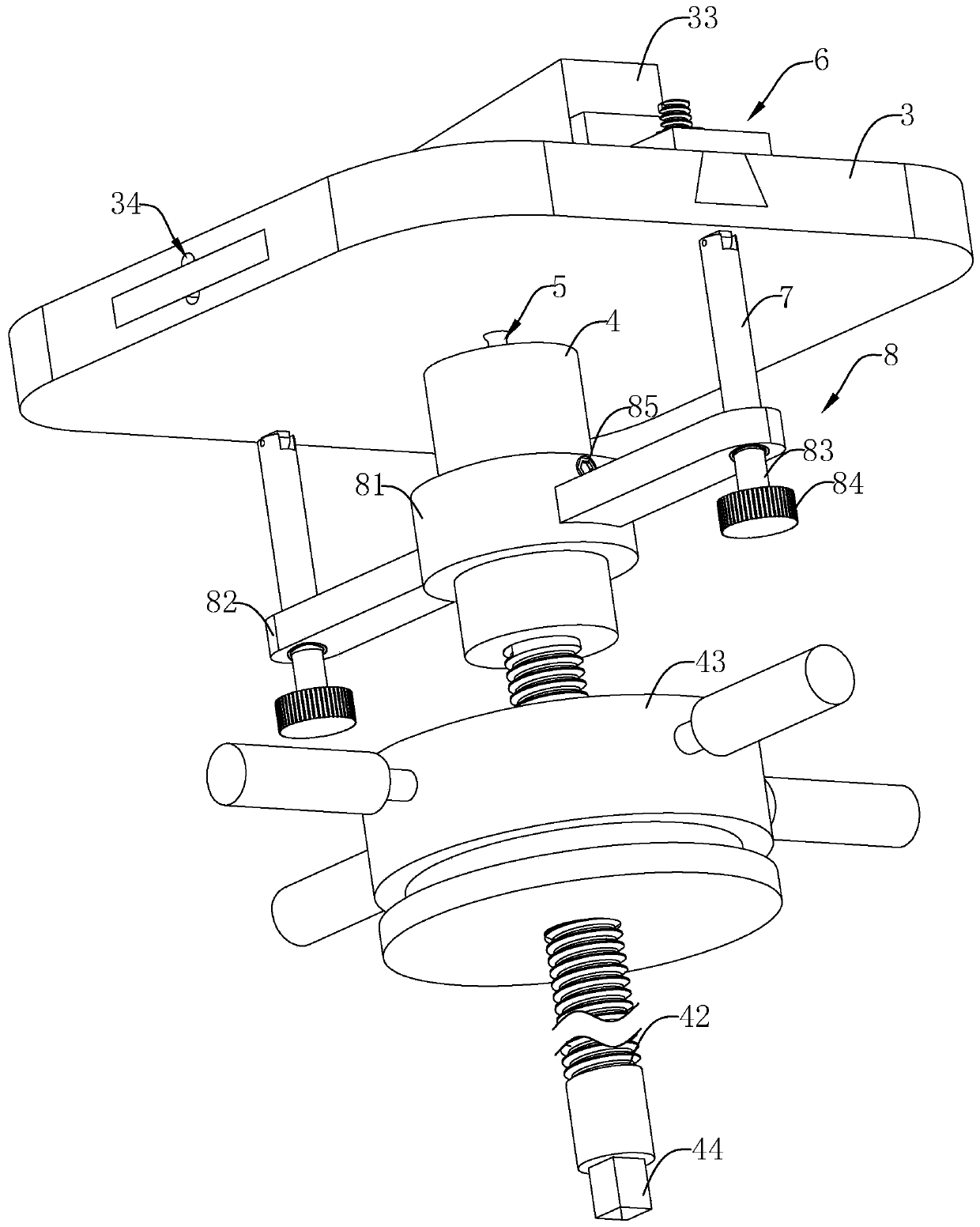

[0043] refer to figure 1 and figure 2 , is a Rockwell hardness tester with the function of adjusting the angle of the measuring platform disclosed in the present invention, including a body 1, an indenter 2 and a measuring platform 3, wherein the body 1 includes a base 11, a frame 12 and a Cross arm 13, the three are integrally connected and C-shaped, indenter 2 is installed on the lower surface of cross arm 13, measuring platform 3 is rectangular, and it is arranged directly below indenter 2, and lifting column is provided on base 11 4. The middle position of the lower surface of the measurement platform 3 is provided with a connecting piece 5 hingedly arranged with the lifting column 4, which includes a mounting block 51 and a connecting rod 52 fixed on the upper surface of the mounting block 51. The connecting rod 52 is connected to the measuring platform 3 They are connected through a ball hinge, and the top of the lifting column 4 is provided with an installation groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com