Drive circuit of power conversion device and power conversion device

A technology of power conversion device and drive circuit, which is applied in the direction of output power conversion device, conversion of AC power input to DC power output, electrical components, etc., which can solve the problem of increasing the number of parallel connections in cost and inability to maximize the performance of power semiconductor components, etc. problem, achieve the effect of improving current unbalance and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Hereinafter, a driving circuit of a power conversion device according to an embodiment of the present invention will be described with reference to the drawings. In addition, the same code|symbol is attached|subjected to the same element in each figure, and overlapping description is abbreviate|omitted.

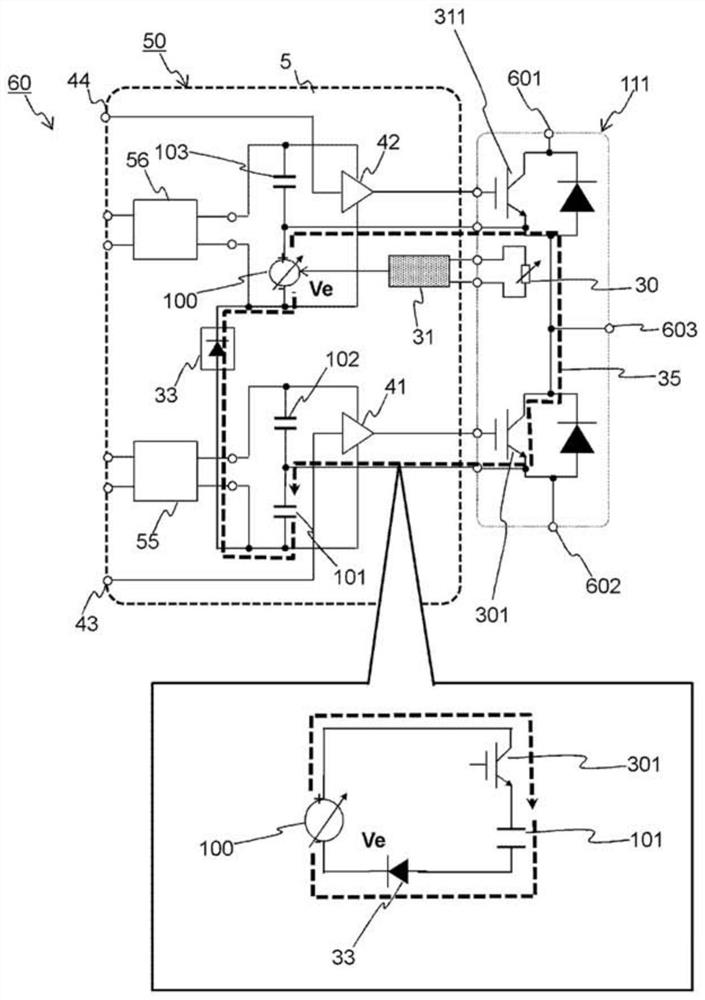

[0032] figure 1 It is a configuration diagram of a power conversion device and its driving circuit according to an embodiment of the present invention.

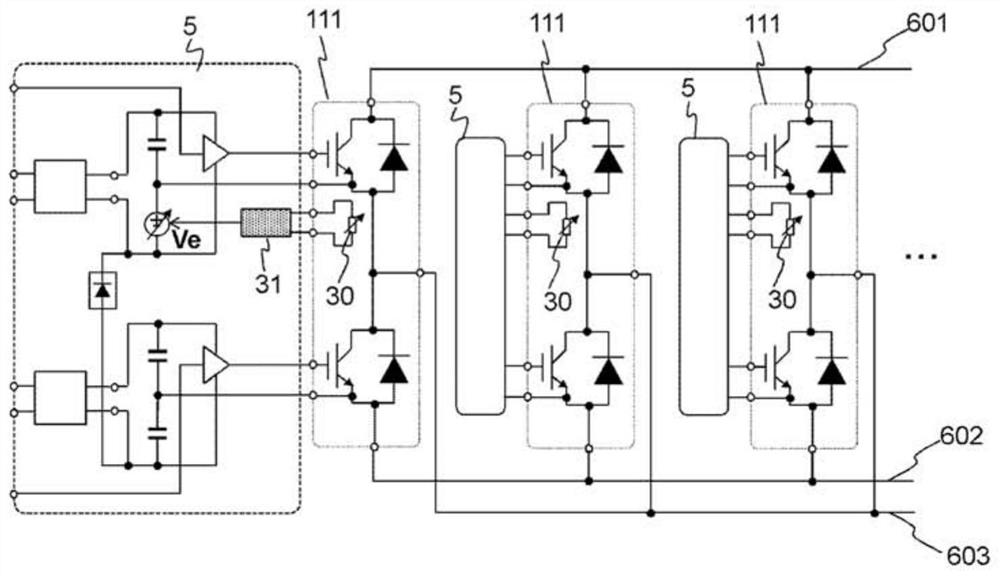

[0033] The power conversion device 60 according to this embodiment includes: a power conversion unit 111 including an upper arm element (upper arm power semiconductor element) 311 and a lower arm element (lower arm power semiconductor element) 301 ; and a drive circuit for driving the power conversion unit 111 50 ; and the temperature sensor 30 (an example of a temperature detection unit) shared by the upper arm element 311 and the lower arm element 301 . As the power semiconductor element, an insulated gate bipolar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com