A high-temperature strain gauge installation process reliability verification device

A high-temperature strain and installation process technology, which is applied to measuring devices, machine/structural component testing, and engine testing, etc., can solve the problems of wasting manpower, material resources, and delaying the progress of engine testing, so as to improve work efficiency and save commissioning costs. , the effect of improving the survival rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

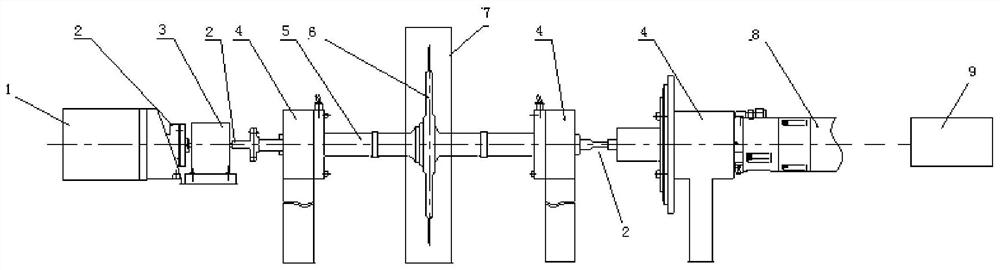

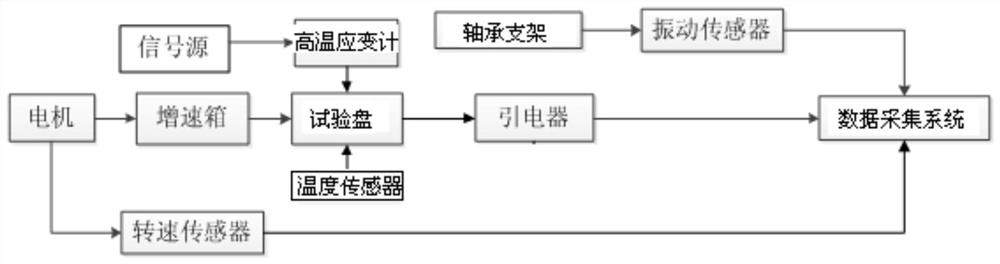

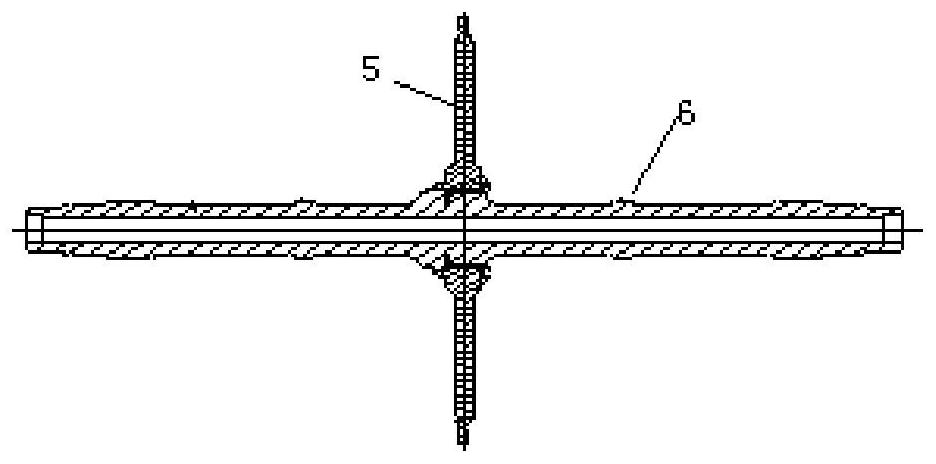

[0021] The present invention will be further introduced below in conjunction with the accompanying drawings. A high-temperature strain gauge installation process reliability verification device according to the present invention includes a motor 1, a speed-increasing box 3, a test plate, a lead-in device 8, a high-temperature heating furnace 7, and a data Acquisition system 9, several bearing brackets 4 and couplings 2, the motor 1 is connected to the speed-up box 3 through the coupling 2, the speed-up box 3 is connected to the test disk through the coupling 2, the The test plate is arranged inside the high-temperature heating furnace 7, the bearing bracket 4 is arranged at both ends of the test plate and the front end of the lead 8, the data acquisition system 9 is connected with the lead 8, the motor 1, the coupling 2, The speed-up box 3 and the bearing bracket 4 form a transmission system for generating a certain centrifugal load on the test disk, so as to simulate the load ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com