Stamping Process of Seat Seat Plate and Its Special Stamping Die

A stamping die and seat plate technology, which is applied in the field of automotive stamping parts, can solve problems such as product formation defects, and achieve the effect of improving stamping pass rate and high stamping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

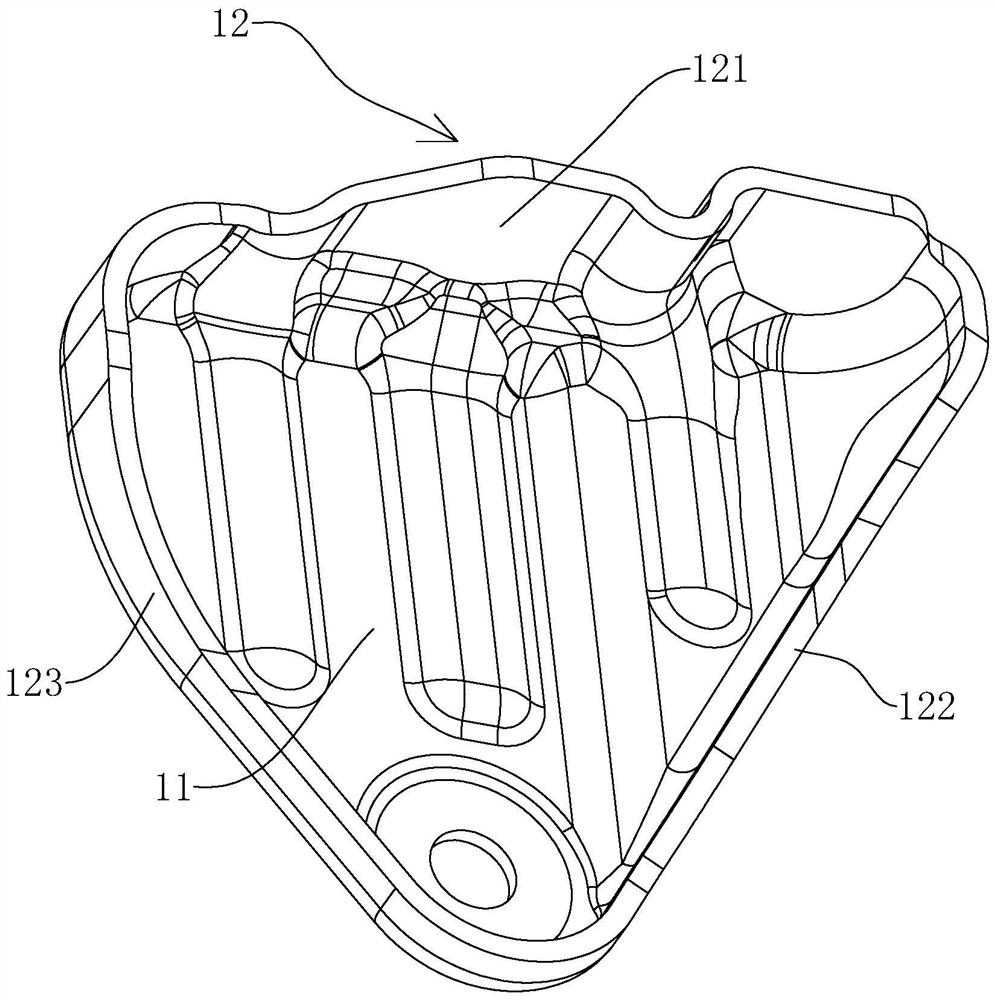

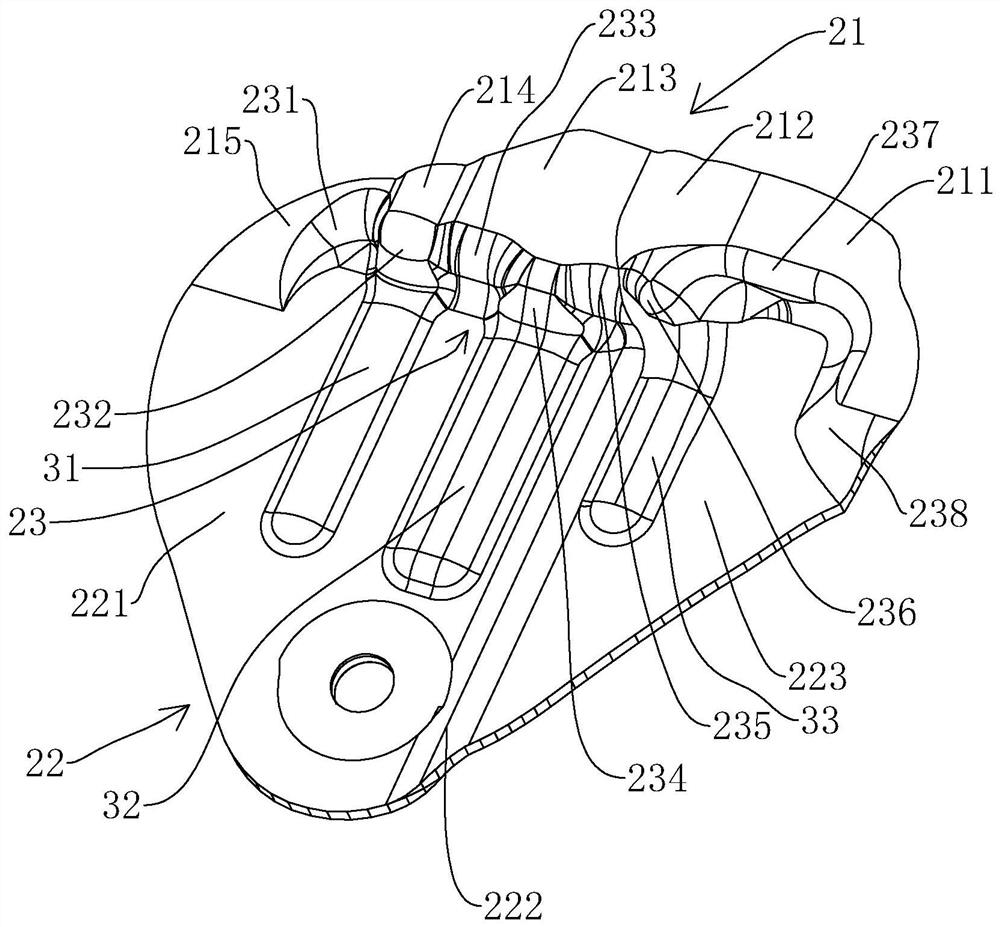

[0027] Embodiment 1: A stamping process for a seat seat plate, such as figure 2 , the flat steel plate 8 to be stamped is stamped once to form the upper planar portion 21 , the lower planar portion 22 , and the tensile transition portion 23 .

[0028] The upper plane portion 21 is higher than the lower plane portion 22, and the upper plane portion 21 includes an upper plane one 211, a first slope 212, an upper plane two 213, an arched surface 214, a second slope 215, and an upper plane one 211 connected in sequence. 213 higher than the upper plane. The first slope surface 212 is obliquely arranged, one end of the first slope surface 212 is connected with the upper plane one 211, the other end is connected with the upper plane two 213, the middle of the arched surface 214 is arched, and the two ends of the arched surface 214 are connected with the upper plane two respectively. 213 is connected with the second slope 215 , and the second slope 215 arcs downward from the end con...

Embodiment 2

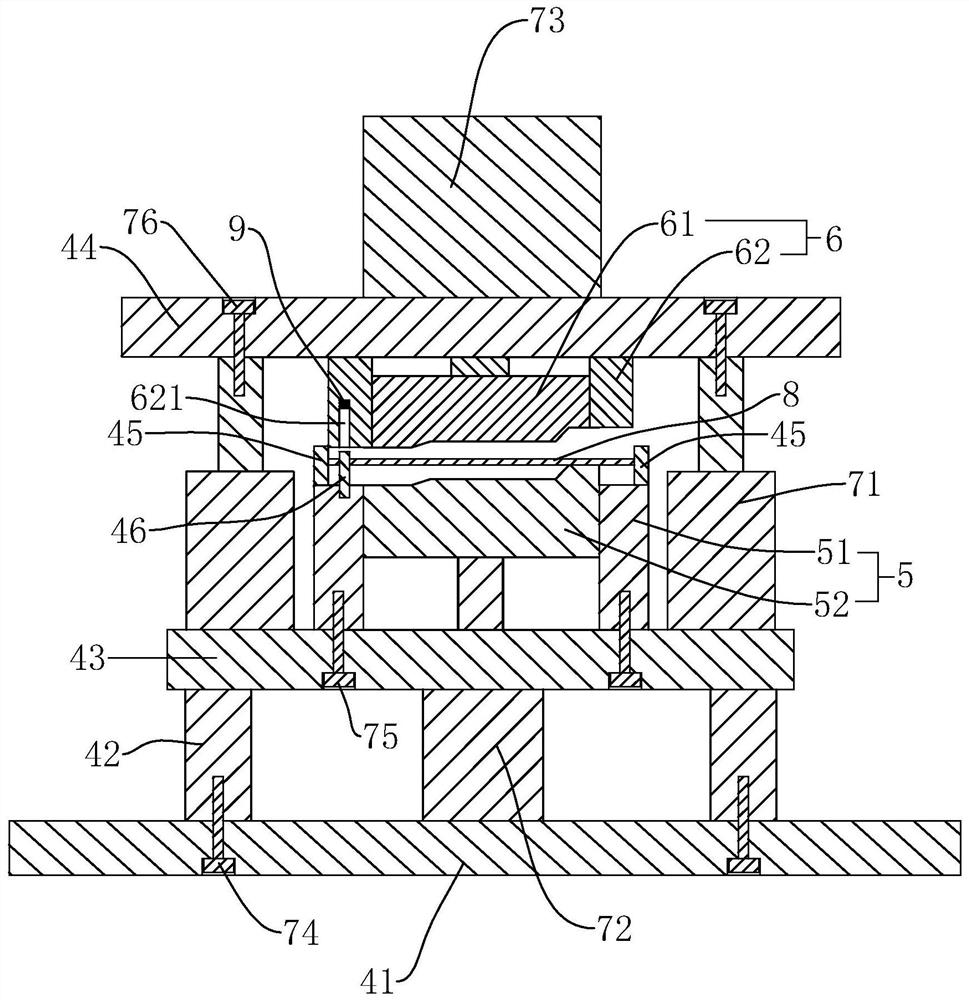

[0040] Embodiment 2: the stamping die that is installed in the stamping process of the seat seat plate, such as image 3 , comprising a support 41, a column 42 fixed above the support 41, a bottom plate 43 fixed on the column 42, a lower mold 5 fixed above the bottom plate 43, a first hydraulic cylinder 71 fixed above the bottom plate 43, and a first The mounting plate 44 on which the piston rod of the hydraulic cylinder 71 is fixed, the upper die 6 fixed on the mounting plate 44 and positioned above the lower die 5 .

[0041] The columns 42 are arranged in two rows, and the second hydraulic cylinder 72 is arranged in the middle of the columns 42 of the two rows. The support 41 and the column 42 are fixed by the first bolt 74 , the first bolt 74 is a counterbore bolt, and the first bolt 74 passes through the support 41 and extends into the column 42 to be threadedly connected with the column 42 . The first hydraulic cylinder 71 is arranged in two rows, and the lower mold 5 is l...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap