Ultralow-inclusion cold-rolled thin strip for high-speed stamping and steelmaking optimization method thereof

A high-speed stamping, ultra-low technology, applied in the field of thin strip, which can solve problems such as surface damage

Active Publication Date: 2021-03-12

ANGANG STEEL CO LTD

View PDF11 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] In the high-speed stamping process, the damage of inclusions to the steel plate is mainly related to the type, size, and position of the inclusions in the thickness direction of the steel plate. In IF steel and ordinary low-carbon steel, except for a small amount of aluminum oxide inclusions compounded with Mg and Ca, most of them are Mainly single particle alumina; the larger the inclusion size, the greater the stress concentration caused, and the stronger the damage to the steel plate; the position of the inclusion in the steel plate determines the degree of damage, and a certain size inclusion is 1 / 2 or 1 / 3 range, due to the long distance of stress transmission to the surface, it is not easy to cause damage to the surface of the steel plate, but when the inclusion is within 1 / 4 or closer to the surface, the stress concentration is easily transmitted to the surface are released to wreak havoc on surfaces

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

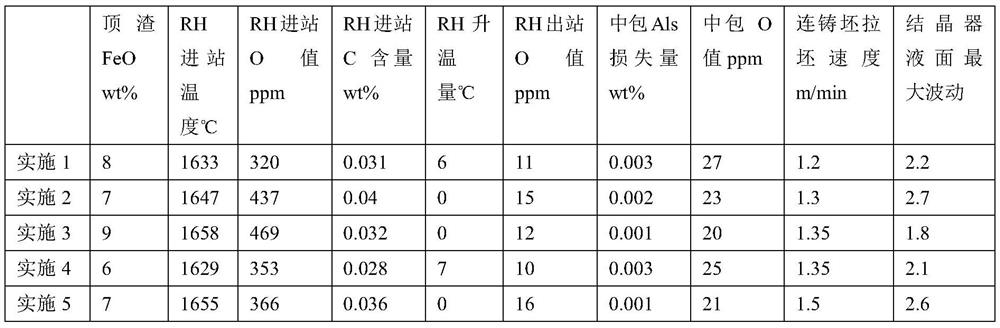

[0022] Table 1 is the steelmaking control parameter of embodiment 1-5;

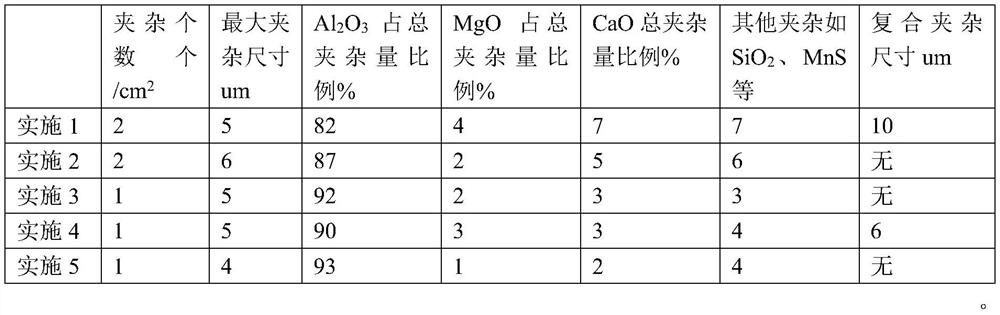

[0023] Table 2 is the inclusion situation of the finished strips of Examples 1-5.

[0024] Table 1 Steelmaking parameter control table

[0025]

[0026] Table 2 Inclusions of the finished strips obtained under the control of the parameters in Table 1

[0027]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to view more

Abstract

The invention discloses an ultralow-inclusion cold-rolled thin strip for high-speed stamping. The number of inclusions in a steel plate is smaller than 3 / cm2 in the section in any thickness direction,the size of the maximum single inclusion is smaller than 8 mum, inclusion particles with the size larger than 6 mum do not exist in the range of 1 / 4 of the distance between the thickness direction and the outermost surface of the steel plate, the total size of the existing oxide composite inclusion particles is smaller than 15 mum, and the oxide composite inclusion particles are arranged in a spherical intermittent rolling direction. Compared with the prior art, the ultralow-inclusion cold-rolled thin strip for high-speed stamping and a steelmaking optimization method thereof have the advantages that the number of the inclusions in the thin strip steel plate is extremely small, the size of the inclusions is extremely small, the stamping percent of pass is high, and the stamping speed canreach 300 times / min or above.

Description

technical field [0001] The invention relates to the field of thin steel strips, in particular to an ultra-low inclusion cold-rolled thin strip for high-speed stamping and a steelmaking optimization method thereof. Background technique [0002] With the improvement of economical and environmentally friendly social conditions, the thickness of steel plates is required to be greatly reduced without loss of performance, especially in the fields of household appliances and automobiles. At present, tin-plated sheets can reach below 0.2mm, and automobiles and civilian battery cases can be used. Reaching below 0.25mm, the thinning of the thickness also greatly improves the self-weight of the car. [0003] The improvement of production efficiency requires that the production speed in many processing fields needs to be greatly increased. For example, the stamping process of battery case has reached an astonishing 300 pieces / min from the previous 30 pieces / min, and the stamping speed h...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more Patent Type & Authority Applications(China)

IPC IPC(8): C21C7/10B22D11/00

CPCC21C7/10B22D11/00

Inventor 杨洪刚吕家舜李峰刘军友高洪涛辛鑫徐闻慧王永明

Owner ANGANG STEEL CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap