Punch automatic feeding system

An automatic feeding and punching technology, applied in the directions of sending objects, processing thin materials, separating objects, etc., can solve the problems of high labor intensity of workers, slow processing speed, hidden safety hazards, etc., to reduce labor intensity of workers, improve stamping pass rate, Reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

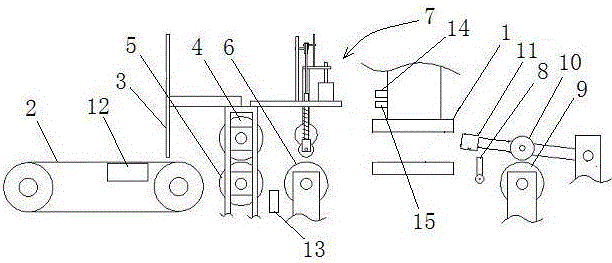

[0019] like figure 1 The punch automatic feeding system shown includes a feeding device and a discharging device respectively arranged on both sides of the punching machine 1; The device includes a flap fence 8 and a feeding mechanism arranged in sequence from the punch press 1 to the outside;

[0020] It also includes a PLC programmable logic controller as a system controller, and a material detection sensor 11, a conveying control sensor 13, a punch high sensor 14 and a punch low sensor 15 whose output is connected to the input of the system controller, and the material detection sensor 11 And transmission control sensor 13 adopts infrared sensor, described punch high position sensor 14 and punch low position sensor 15 adopt proximity sensor, whether there is material between described material detection sensor 11 detection punch press 1 and turnover plate by grid 8, described transmission control sensor 13 Detect whether there is material between the push mechanism and the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap