Distributing and collecting device, microchannel heat exchanger and heat pump air conditioner

A micro-channel heat exchanger and collector technology, applied in indirect heat exchangers, heat exchanger types, evaporators/condensers, etc., can solve problems such as uneven distribution of refrigerants in micro-channel heat exchangers, and achieve structural Simple and reliable, high efficiency, the effect of reducing the amount of charge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0026] In order to make the objectives, technical solutions and advantages of the implementation of the present invention clearer, the technical solutions in the embodiments of the present invention will be described in more detail below in conjunction with the accompanying drawings in the embodiments of the present invention.

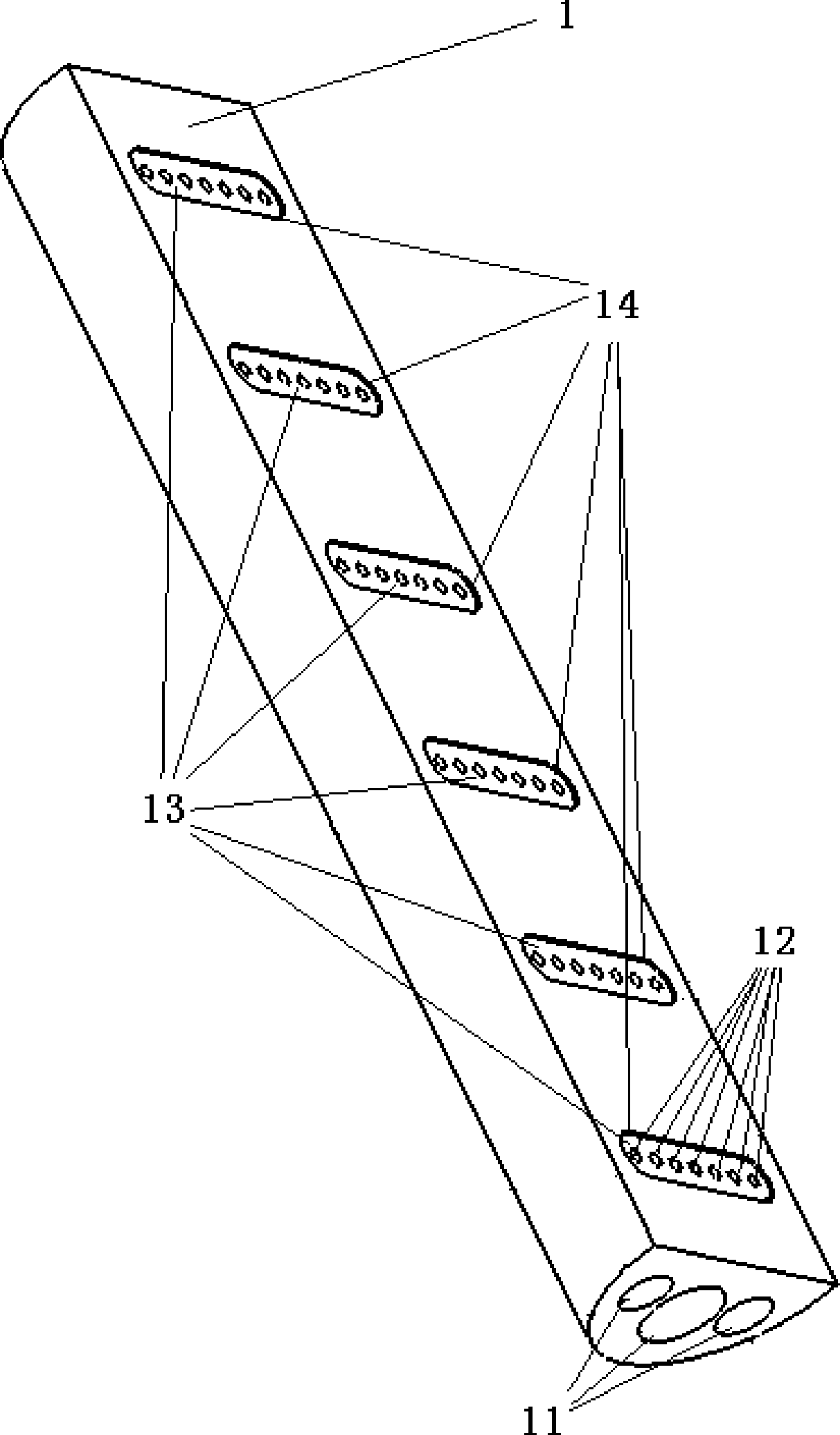

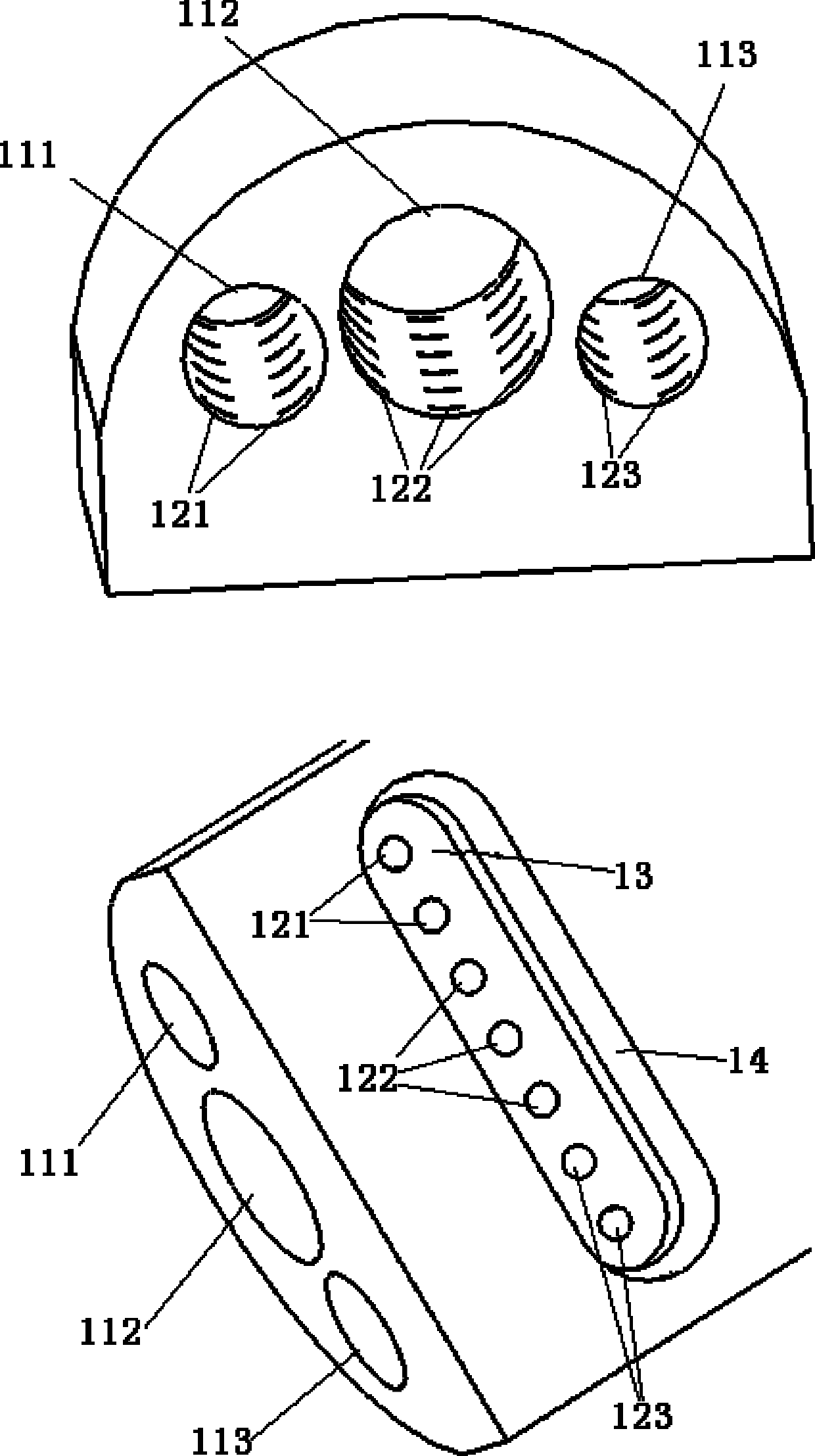

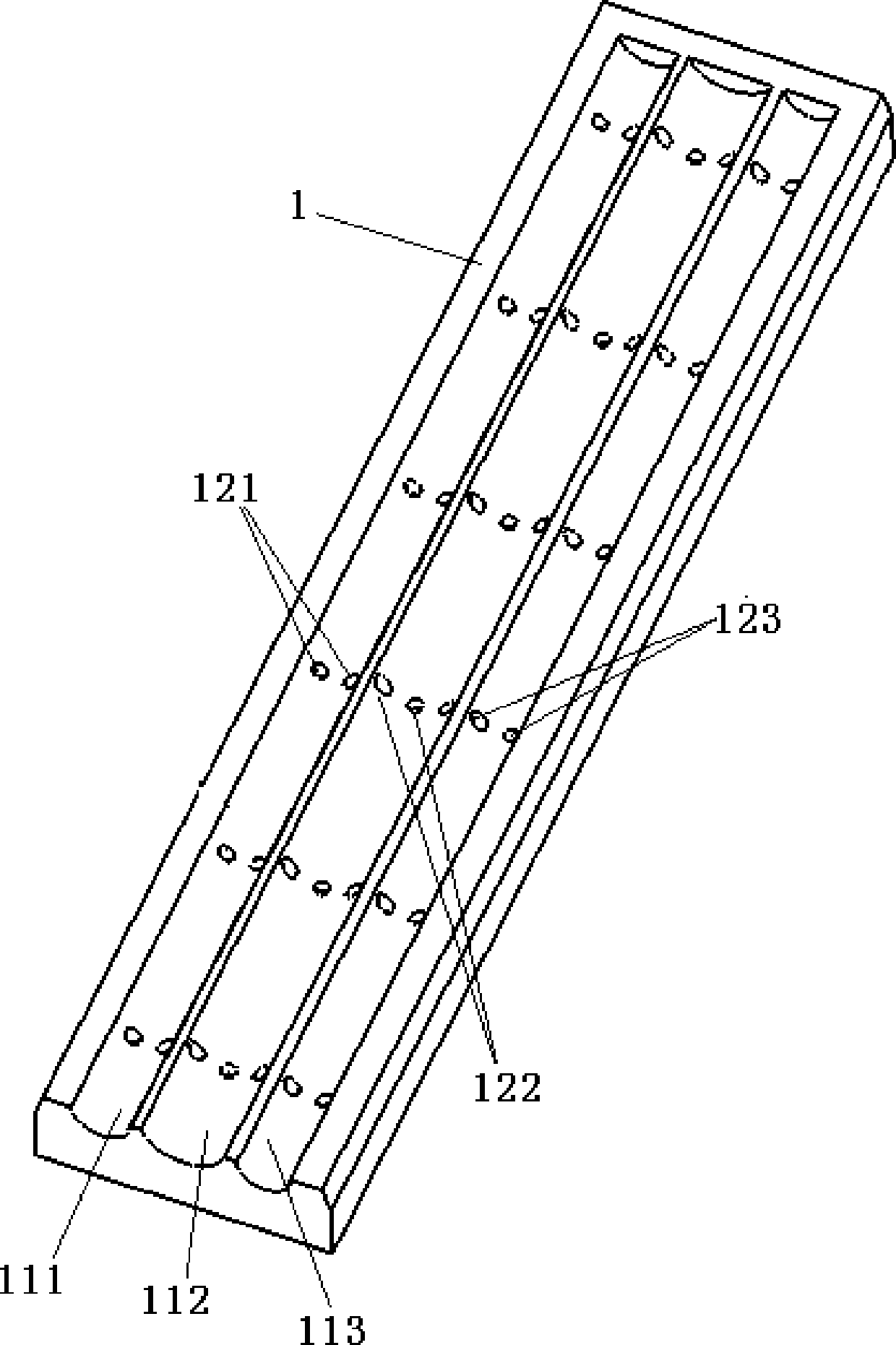

[0027] Embodiment 1 of a diversity current collector provided by the present invention is as attached figure 1 , 2 , 3, the branch pipe (11) arranged side by side in the manifold (1) body includes the first branch pipe (111), the second branch pipe (112), the third branch pipe (113), the first branch pipe (111) A plurality of equalizing holes (121) are provided on the pipe wall, a plurality of equalizing holes (122) are provided on the pipe wall of the second branch pipe (112), and a plurality of equalizing holes (122) are provided on the pipe wall of the third branch pipe (113). Orifice (123), a plurality of liquid equalizing cavities (13) are arranged on...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap