A non-contact micro-vibration visual measurement method

A micro-vibration and visual measurement technology, applied in the field of computer vision, can solve problems such as measurement and analysis of micro-vibration signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

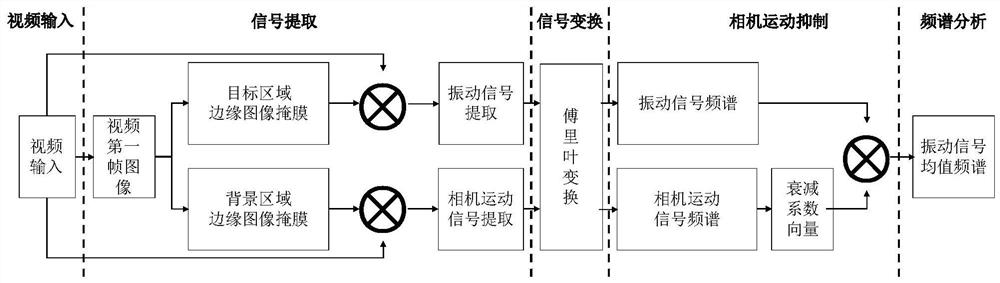

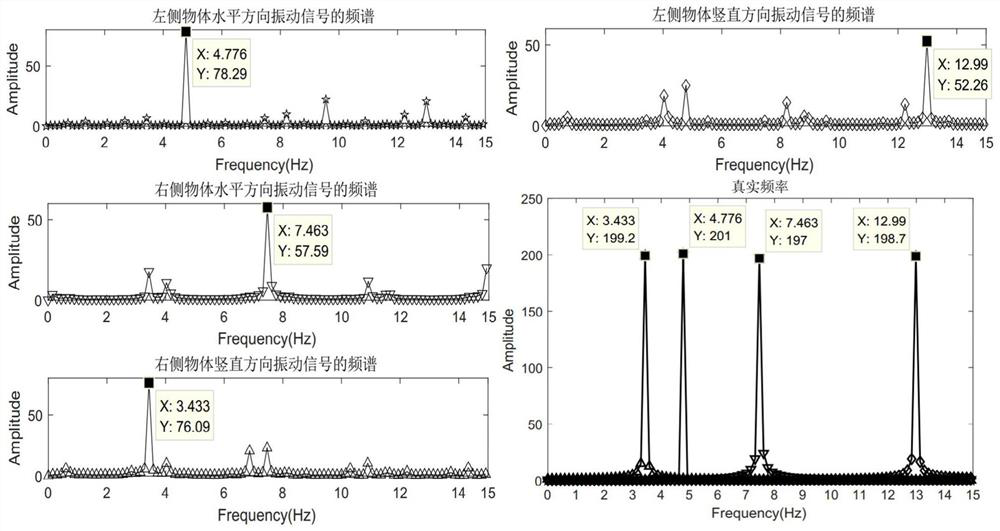

[0030] combine figure 1 , the non-contact micro-vibration visual measurement technology of the present invention comprises the following steps:

[0031] Step S1: collect video data of vibrating objects in nature to extract tiny vibration signals;

[0032] In this step, according to an embodiment of the present invention, specifically:

[0033] 1a) A Canon camera EOS 600D is used to capture a video of a vibrating object in a natural environment. The frame rate of the camera is 50 frames per second, the image resolution is 1280×720, the video acquisition time is 7 seconds, and it is saved in avi video format. Using color space conversion, it is converted from RGB space to YIQ space, and the video sequence of Y (brightness) channel is extracted for subsequent analysis.

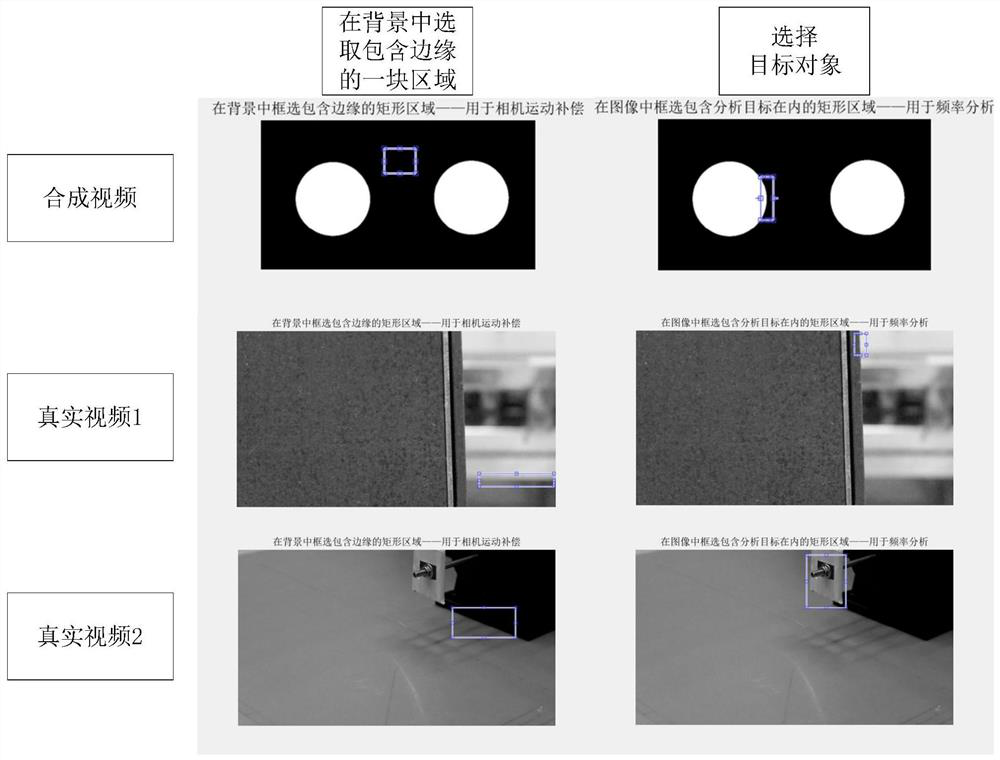

[0034] 1b) Extract the first frame image in the video sequence, and manually select the vibration target region (ROI); use the canny operator to detect its edge, and then generate an edge mask Image Mask with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com