A method for testing the quality of concrete crack repair

A quality inspection method and crack repair technology, which is applied to measuring devices, instruments, and the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., can solve the problem of unrepaired, inability to make judgments, and quantitative determination of the degree of repair of cracks inside concrete. Issues such as the accurate depth of the area, to achieve the effect of reliable data support and reduce the workload of the later stage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] In this example, the overall technical solution is as follows:

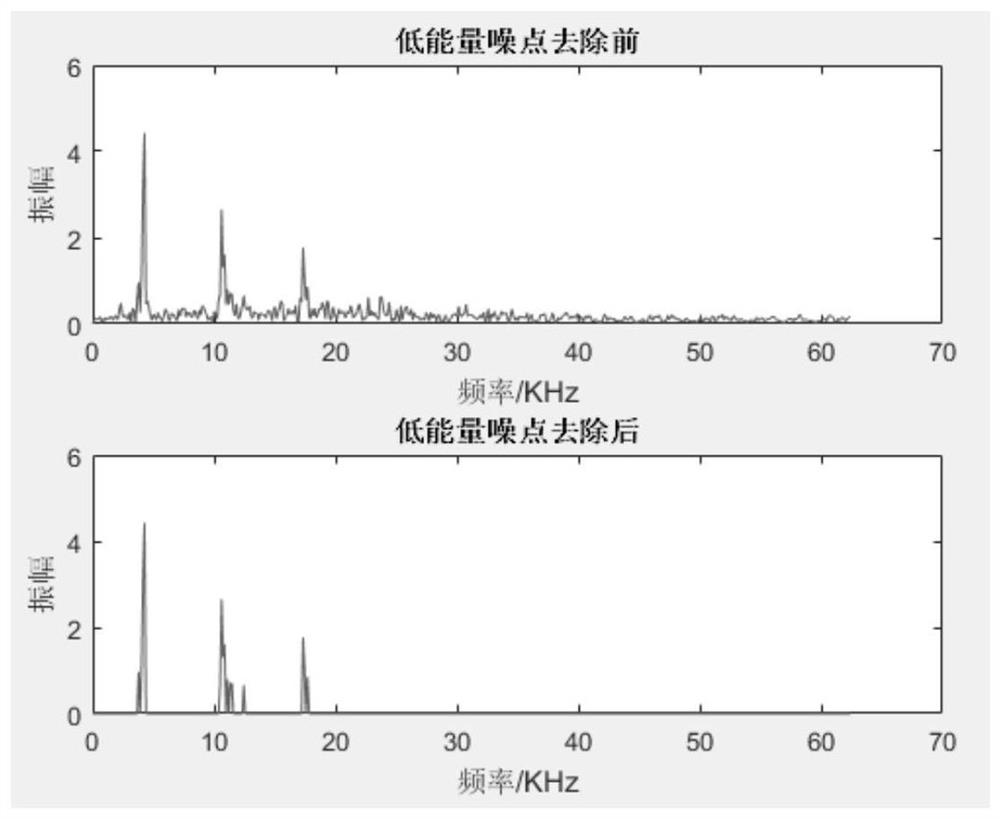

[0060] Remove noise in spectrogram

[0061] Since the energy of the wave is proportional to the square of the wave amplitude and the amplitude of the spectrogram after Fourier transform is proportional to the signal amplitude, the low-energy noise introduced during crack detection can be screened according to the amplitude of the spectrum to reduce Computational amount for defect frequency extraction. According to the crack spectrogram, it can be found that the amplitude range of most low-energy noise points is relatively concentrated. Therefore, the comprehensive mathematical statistics of the amplitudes of different crack spectrograms find that 95% of the amplitudes are in the low amplitude range. Based on this, it is determined For the maximum amplitude points within this range, the amplitude points in the amplitude-frequency characteristics of the fracture are screened one by one. If the frequency amp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com