Big-gradient bottling container standing type conveying device

A conveying device and technology with a large slope, applied in the directions of conveyors, transportation and packaging, can solve the problems of the conveying chain plate detaching from the guide rail, the time-consuming and labor-intensive replacement operation, and the large replacement intensity of the chain plate, so as to achieve smooth conveying and reduce manufacturing costs. and maintenance cost, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

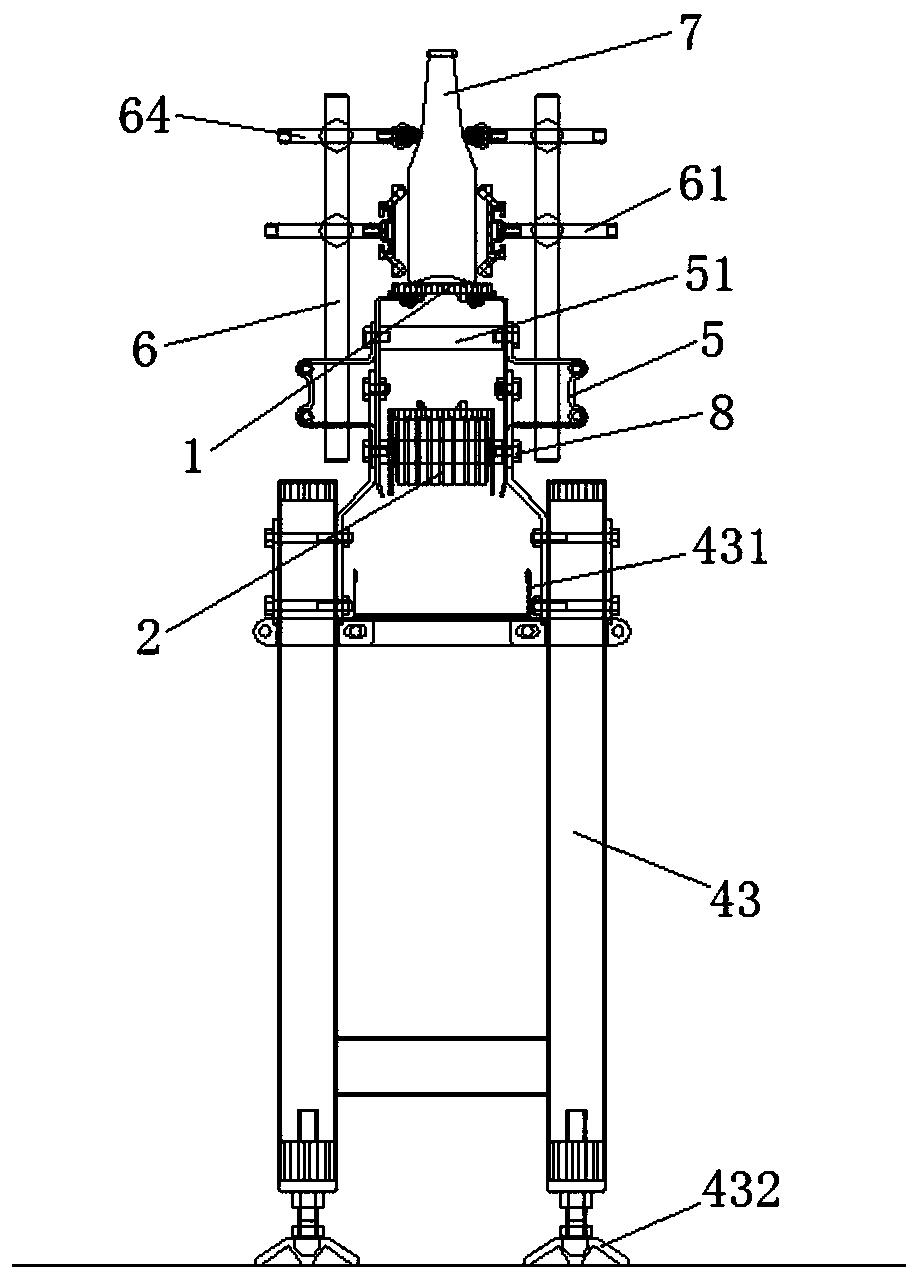

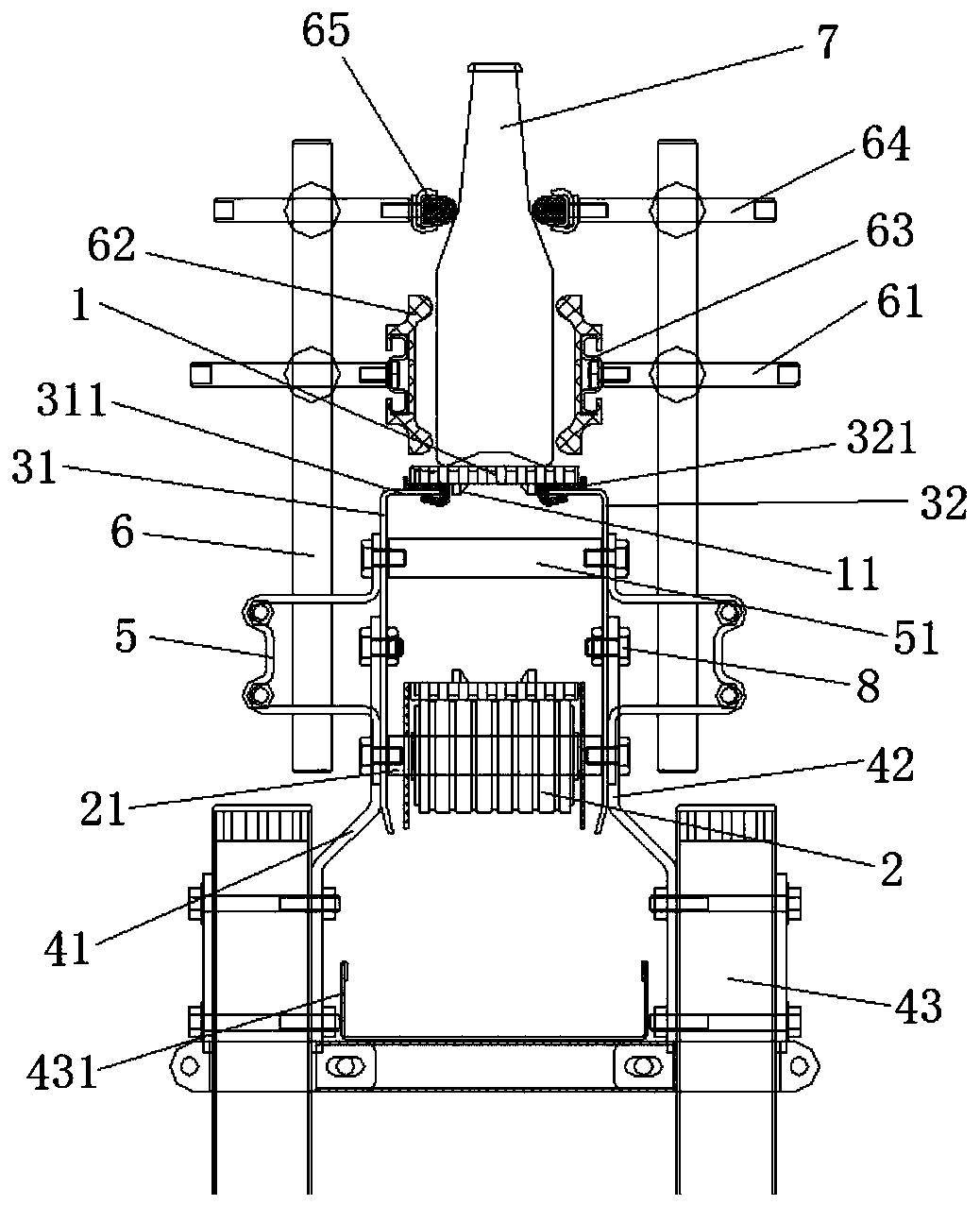

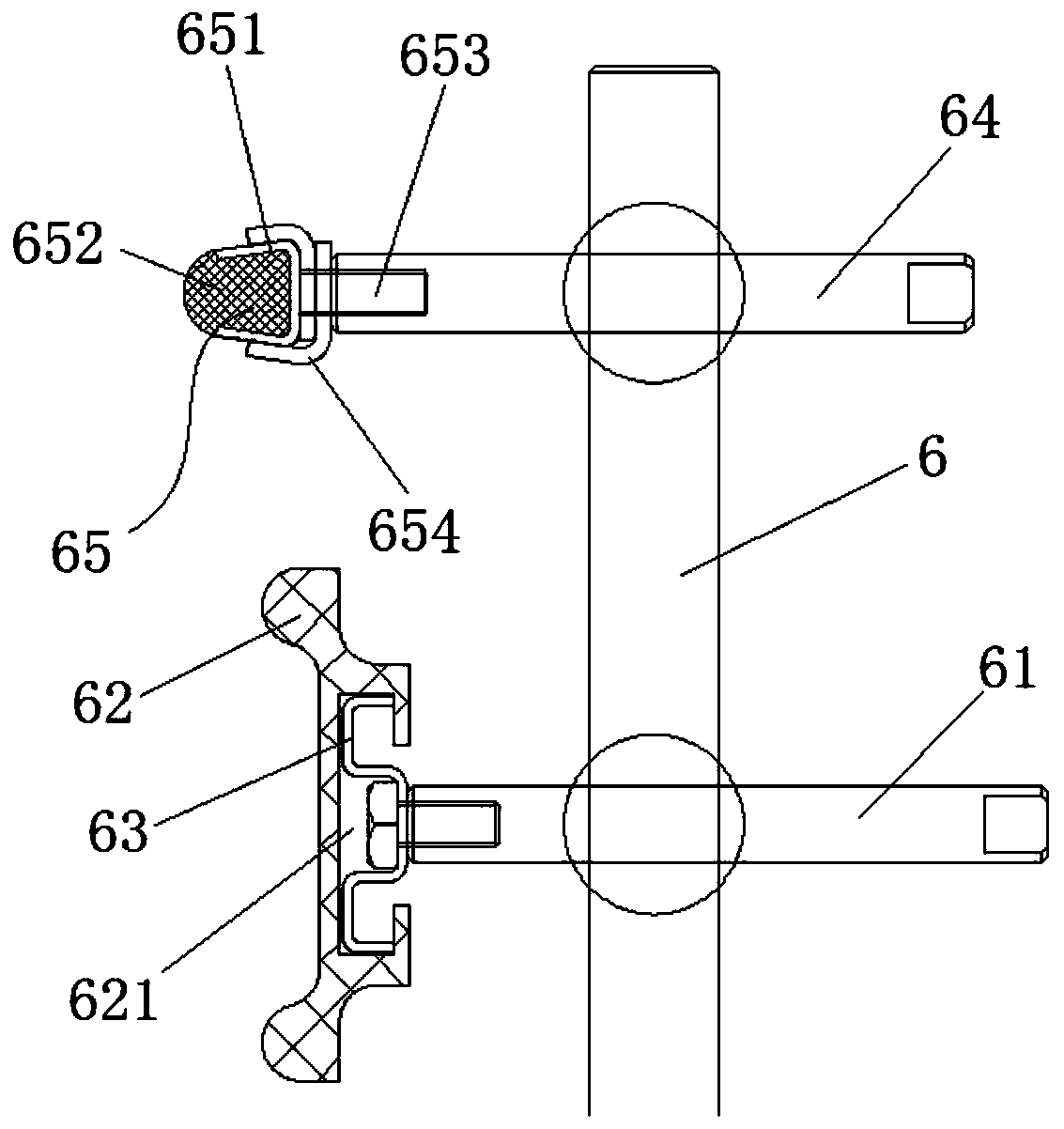

[0029] Such as Figure 1-4 As shown, this embodiment provides a vertical conveying device for bottled containers with a large slope, which mainly includes a conveyor belt, a supporting device and a protective device.

[0030] The conveyor belt is a self-lubricating chain plate 1, and the inner side of the self-lubricating chain plate 1 is provided with a guiding bar 11; the conveying surface of the self-lubricating chain plate 1 is inclined, and the bottle container 7 is standing is placed on the conveying surface of the self-lubricating chain plate 1, and the bottle container 7 is transported from a high place to a low place through the operation of the self-lubricating chain plate 1. In this embodiment, a glass beer bottle is taken as an example for introduction. In fact, the bottled container 7 may also be an industrial filling bottle such as an aluminum bottle or a PET bottle.

[0031] The supporting device includes a mounting frame and a supporting frame, the self-lubric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com