Connecting device and method for phase line composite optical cable of high-voltage power grid

A composite optical cable and high-voltage power grid technology, which is applied in the field of electric power special optical cables, can solve the problems of threatening the safe operation of the power grid and the failure of optical fiber burnout in the splice box, so as to ensure long-term safe operation, solve the problem of blown optical fiber caused by intracavity discharge, and eliminate The effect of cavity induced electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

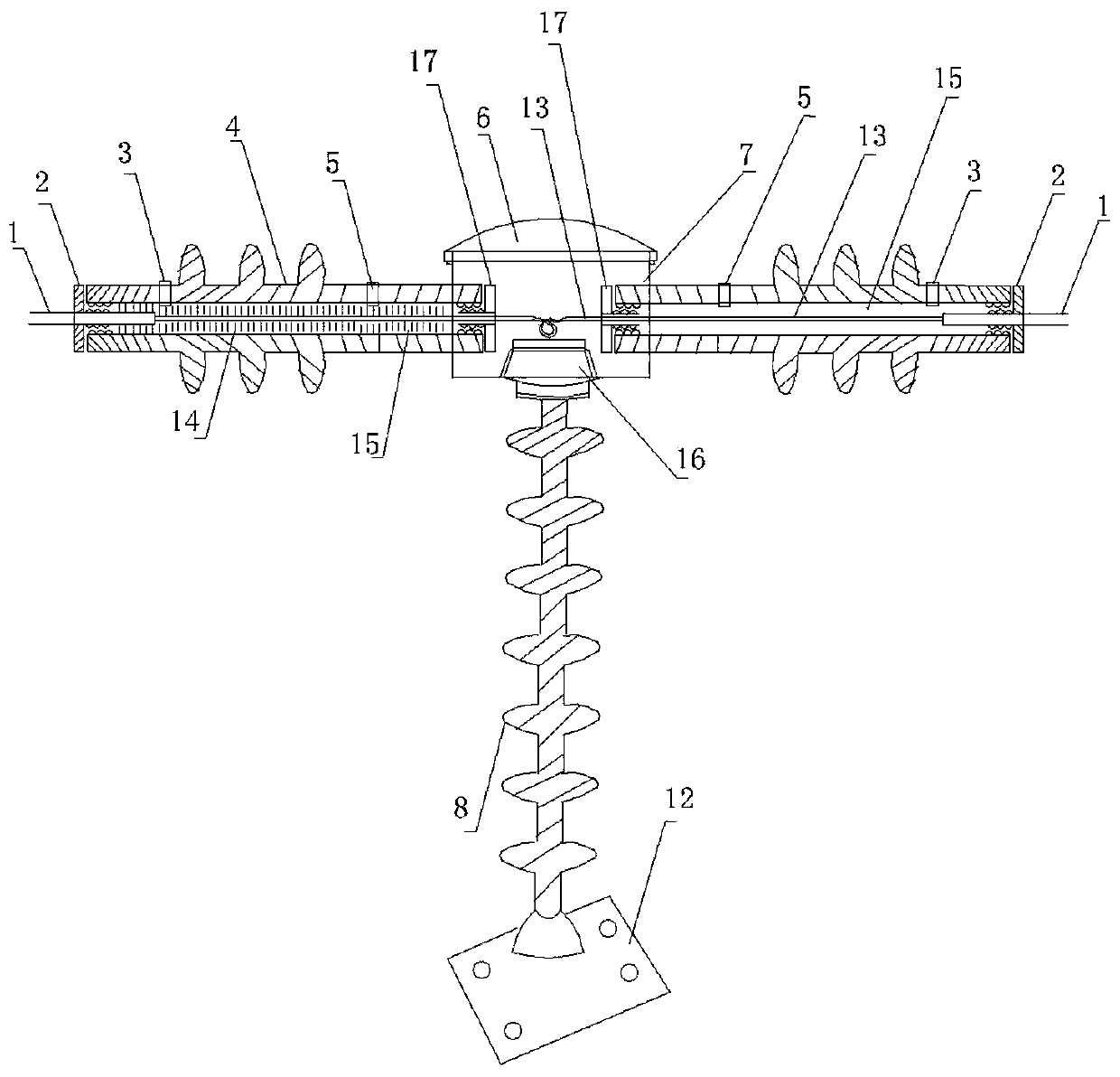

[0022] Such as figure 1 As shown, this splicing device for phase-line composite optical cables of a high-voltage power grid includes: an optical fiber channel insulating jacket 4, a disc fiber cavity 7, an insulating post 8, a base 12, a fiber core channel 15, and a splicing disc 16;

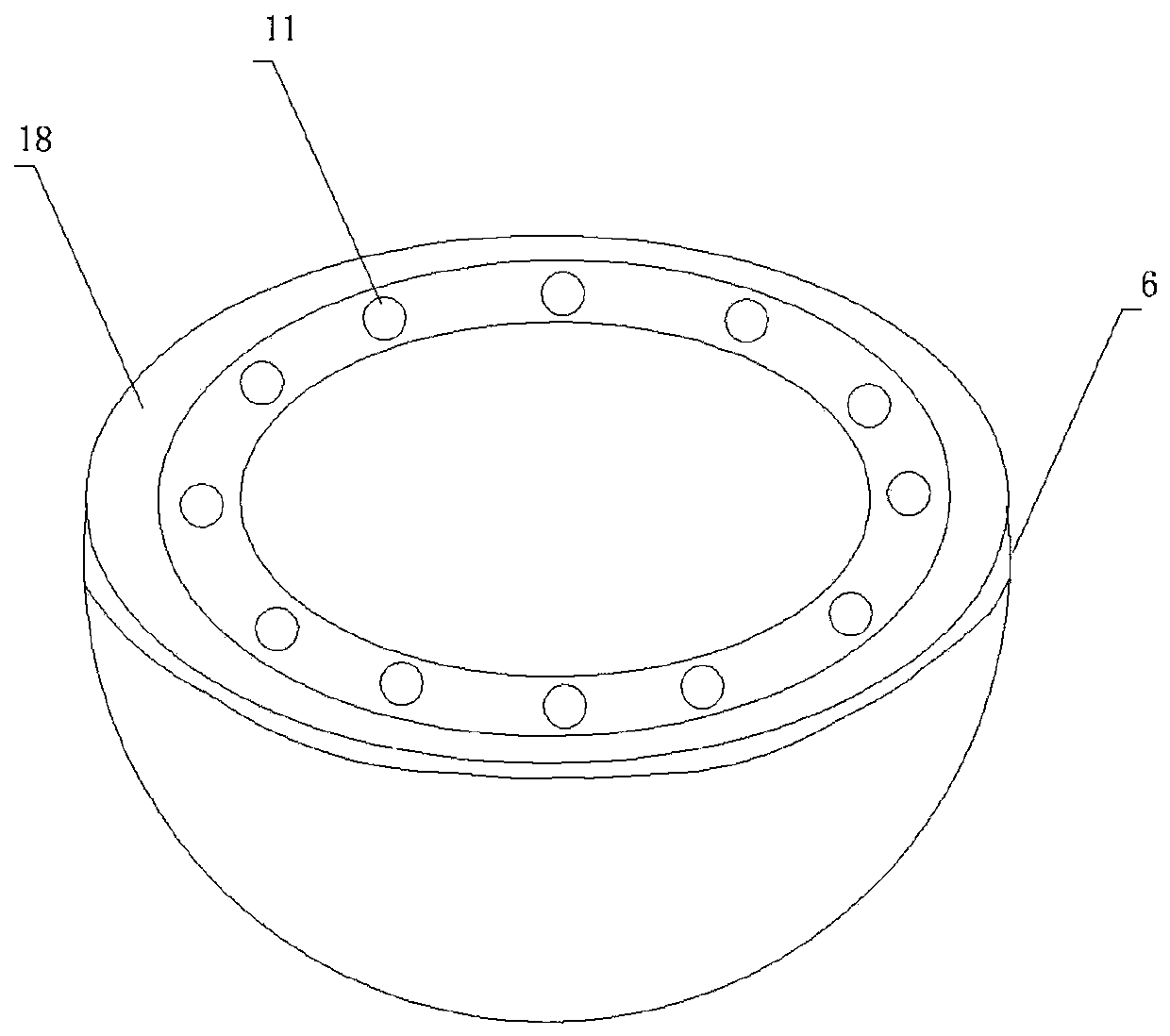

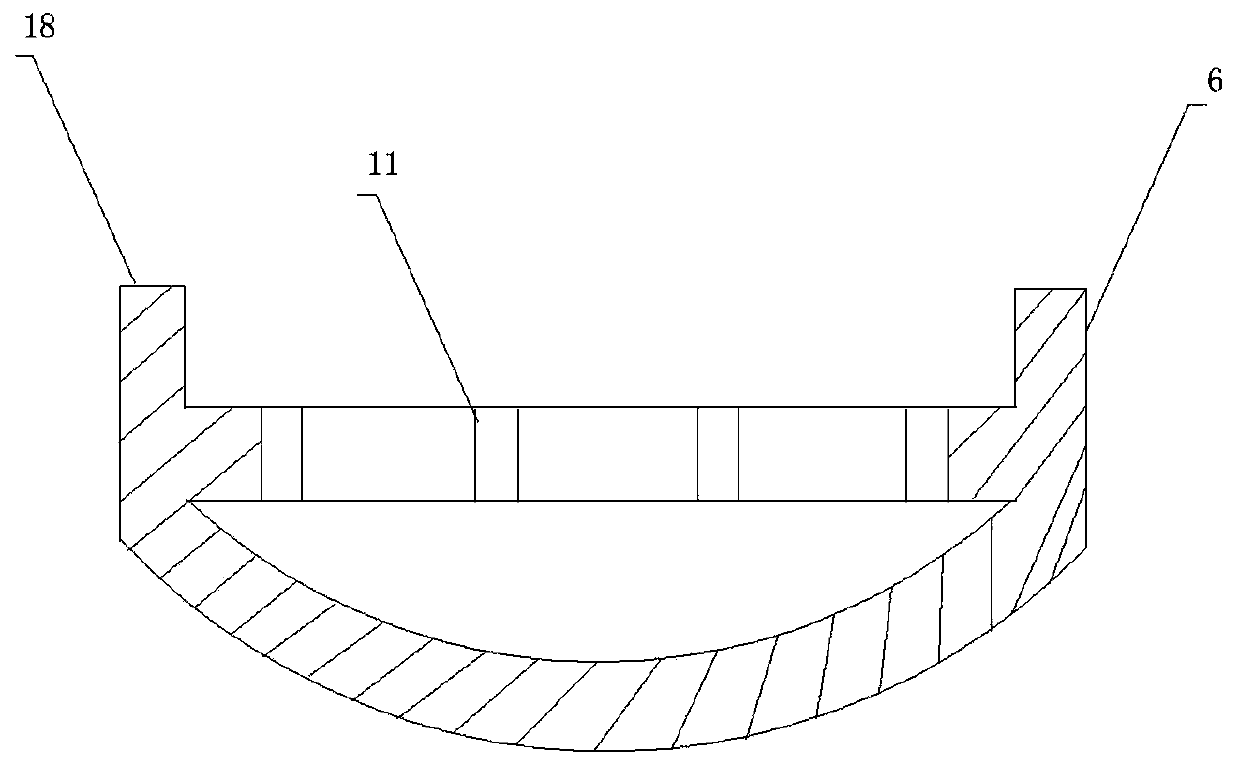

[0023] An insulating support 8 is arranged on the base 12, and a disk fiber chamber 7 is installed on the insulation pillar. The disk fiber chamber 7 has a chamber cover 6 and a fiber fusion disk 16 is placed therein, and the disk fiber chamber and the chamber cover are made of non-metallic insulating materials;

[0024] The fiber channel insulating jacket 4 sets outside the OPPC optical cable 1, the optical fiber 13 stripped from the OPPC optical cable 1 passes through the fiber core channel 15, enters from the left side of the fiber cavity 7 of the disk, and is fused through the fiber splicing tray 16. Right side output of chamber 7;

[0025] A glue injection hole 5 is provided on the left si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com