Full-process management and control platform for Internet of Things waste materials

A management and control platform and Internet of Things technology, applied in the field of material storage, can solve the problems of a large amount of manpower and material resources, the inability to guarantee the accuracy of waste materials to be put in and out of the warehouse, and the complexity of material types, so as to achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

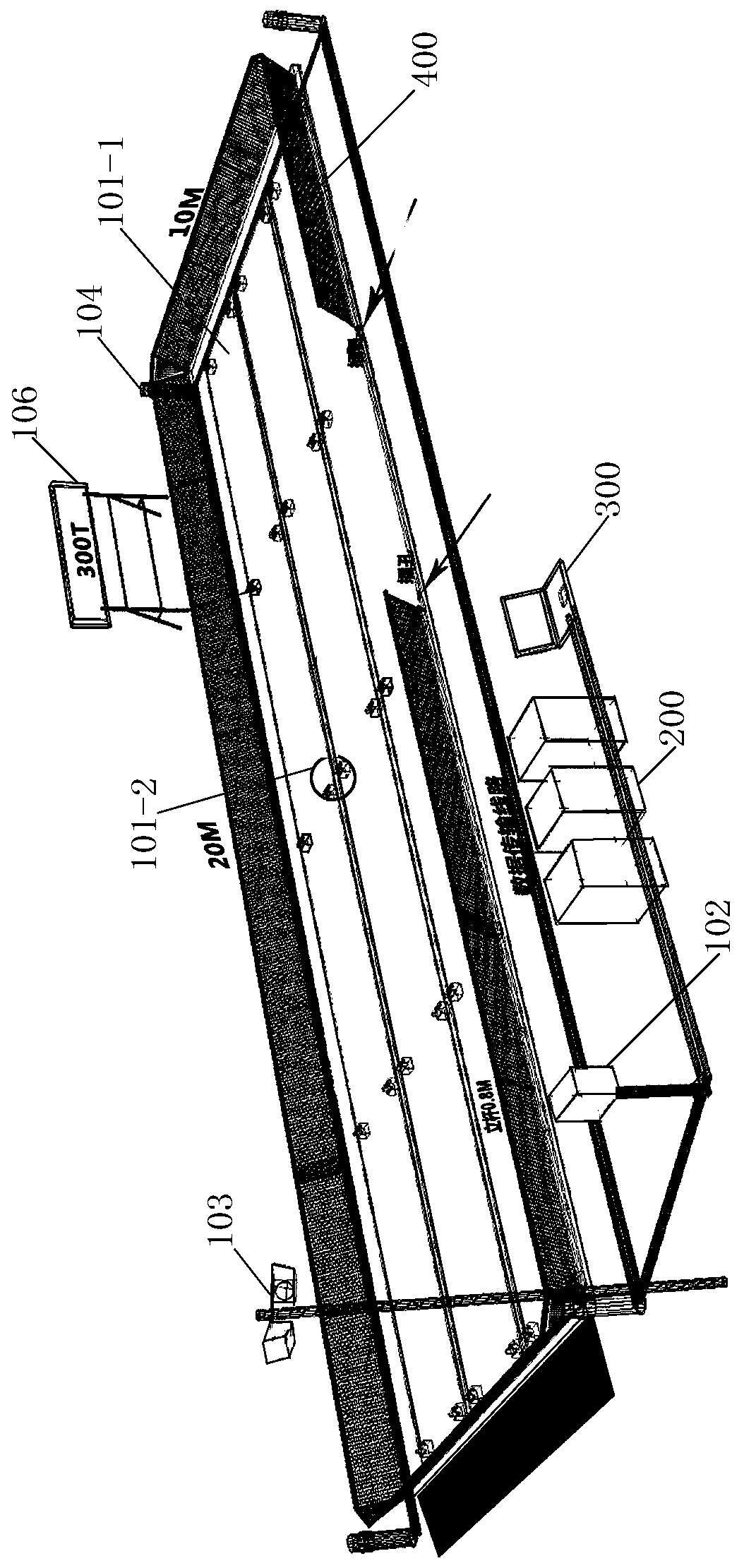

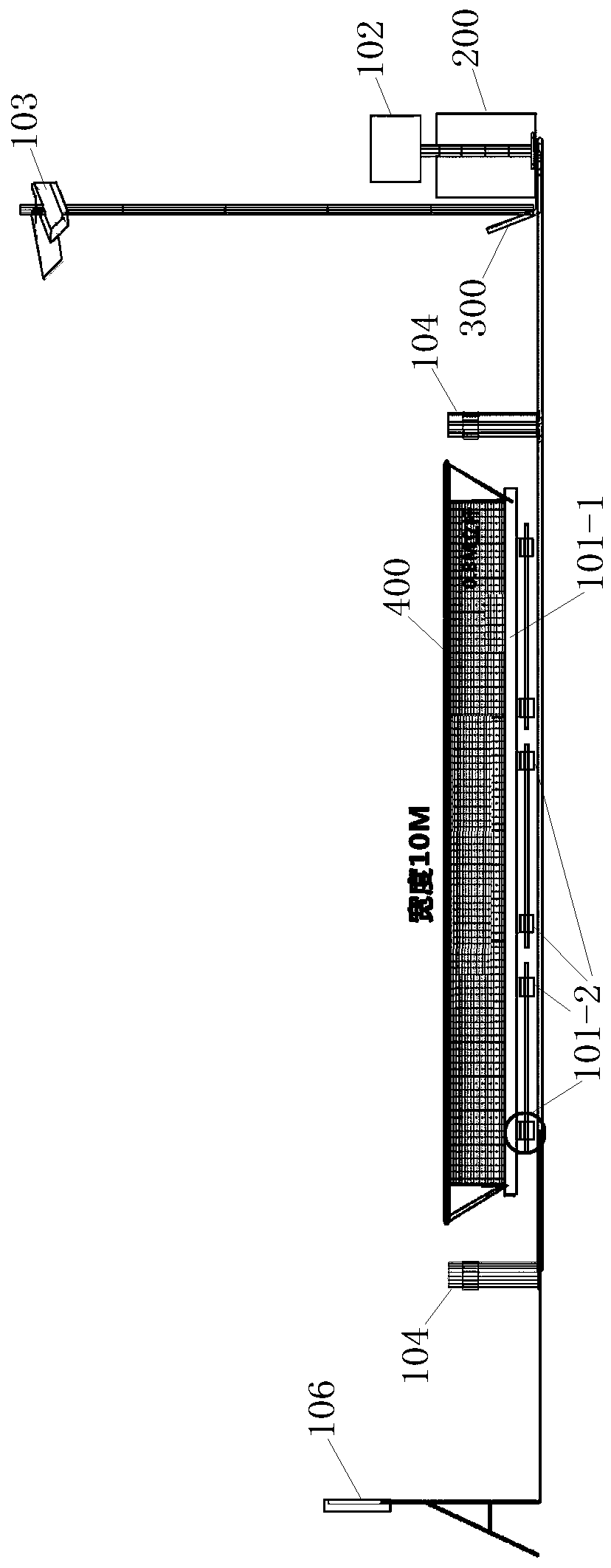

[0076] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. It should be noted that the accompanying drawings in the following description are only some embodiments of the present invention. Under the premise, other drawings can also be obtained based on these drawings.

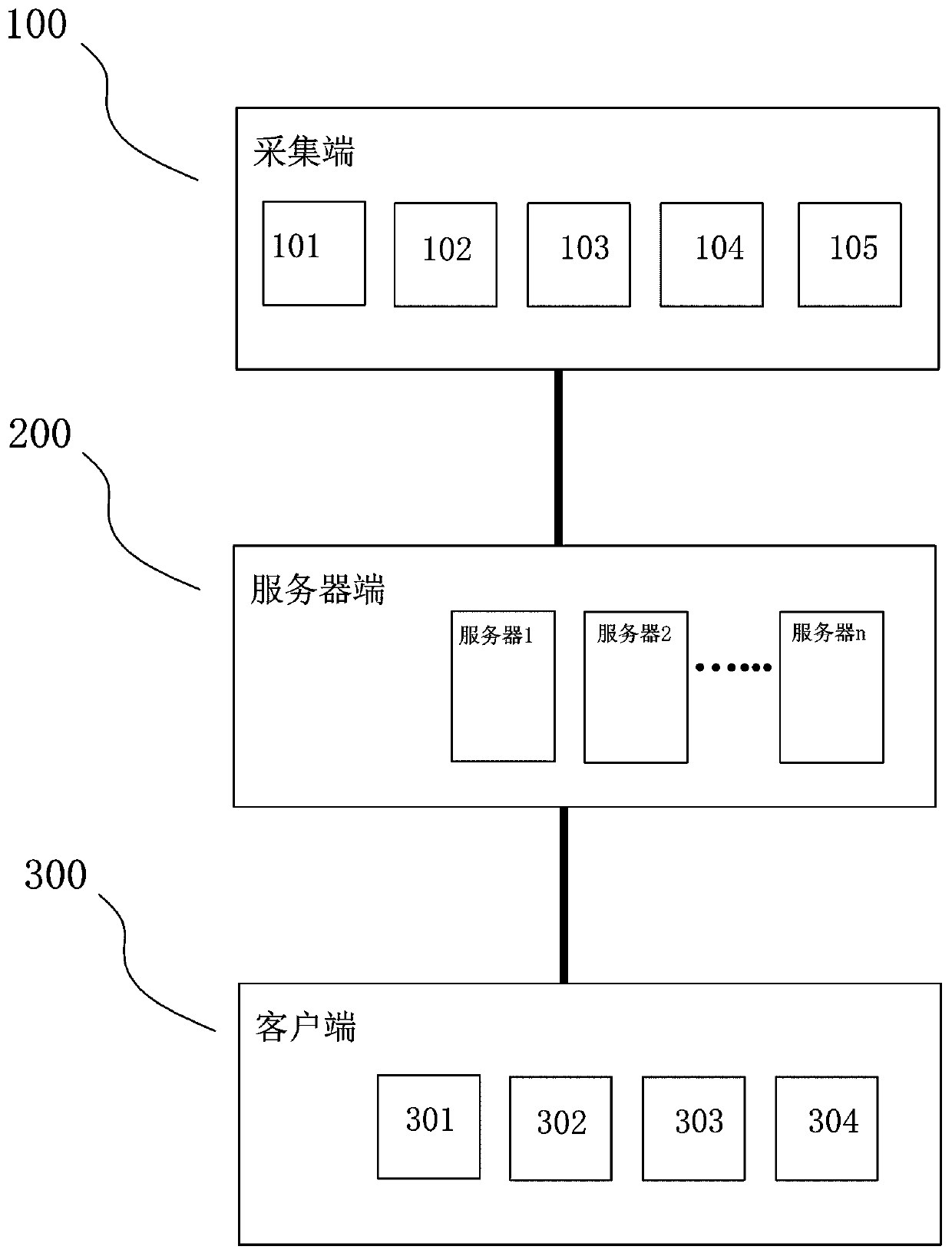

[0077] attached Figure 1-8 As shown, the whole process management and control platform of the Internet of Things waste materials of the present invention includes a signal acquisition unit 100 (that is, the acquisition end in the figure), a monitoring center 200 (the server end in the figure) and an Internet of Things client connected by wired or wireless means 300 (the client in the figure), the signal acquisition unit 100 has a weighing device 101, an Internet of Things signal box 102, a camera 103, an integrated multifunctional sensor 104 and an alarm device 105 arranged at each waste yard site; the collected The waste material weig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com