A loading and unloading fork for an industrial transport forklift

A forklift and industrial technology, applied in the field of forklift forks, can solve the problems of forklift handling, safety accidents, uneven stacking, etc., and achieve the effects of protecting the lumbar spine, improving the load-bearing capacity, and high load-bearing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

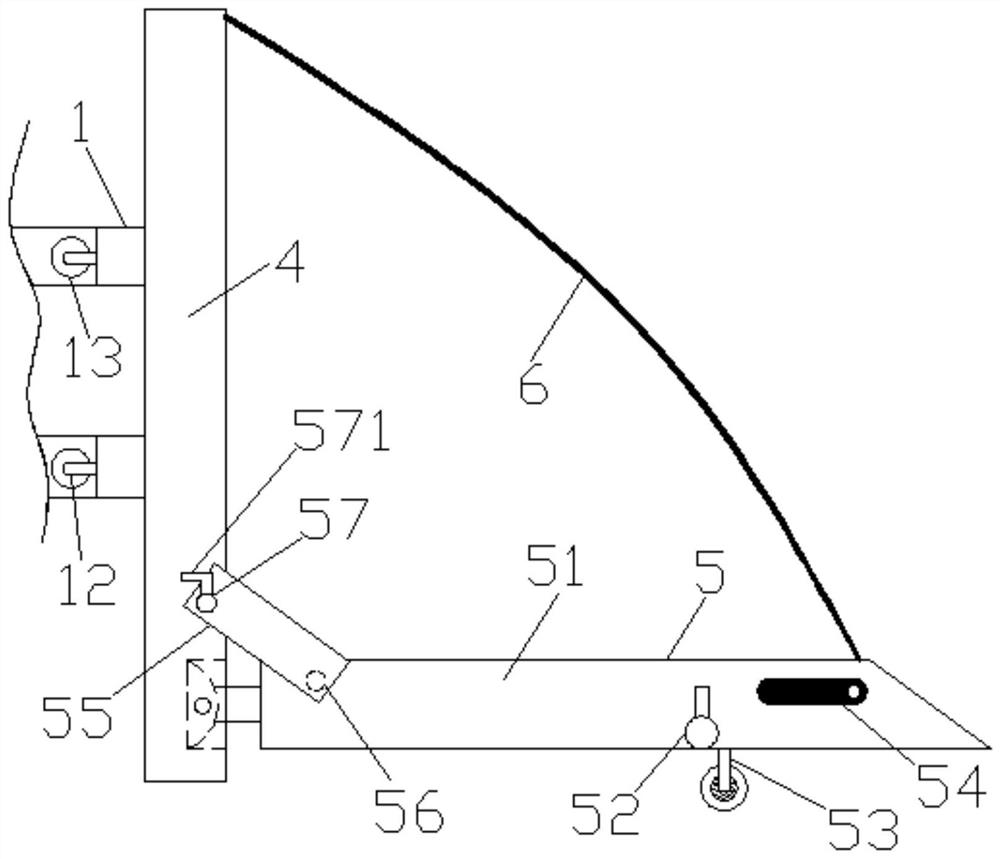

[0032] A loading and unloading fork for an industrial transport forklift, comprising a fork frame arranged in front of the forklift, the fork frame includes a positioning transverse plate 1, a positioning longitudinal plate 2, a positioning support plate 3, an extending longitudinal plate 4 and an extending bottom plate 5, the positioning longitudinal The plate 2 is fixedly connected to the positioning transverse plate 1, the positioning support plate 3 is rotationally connected to the positioning longitudinal plate 2, the extending longitudinal plate 4 is slidingly connected to the positioning transverse plate 1, the extending bottom plate 5 is rotationally connected to the extending longitudinal plate 4, and the extending bottom plate 5 includes the bottom plate Main body 51, anti-skid bolt 52, universal wheel bracket 53, pull rod 54, linkage plate 55, limit hole 56 and fixing pin 57, anti-skid bolt 52 is threadedly connected with base plate main body 51, universal wheel brack...

Embodiment 2

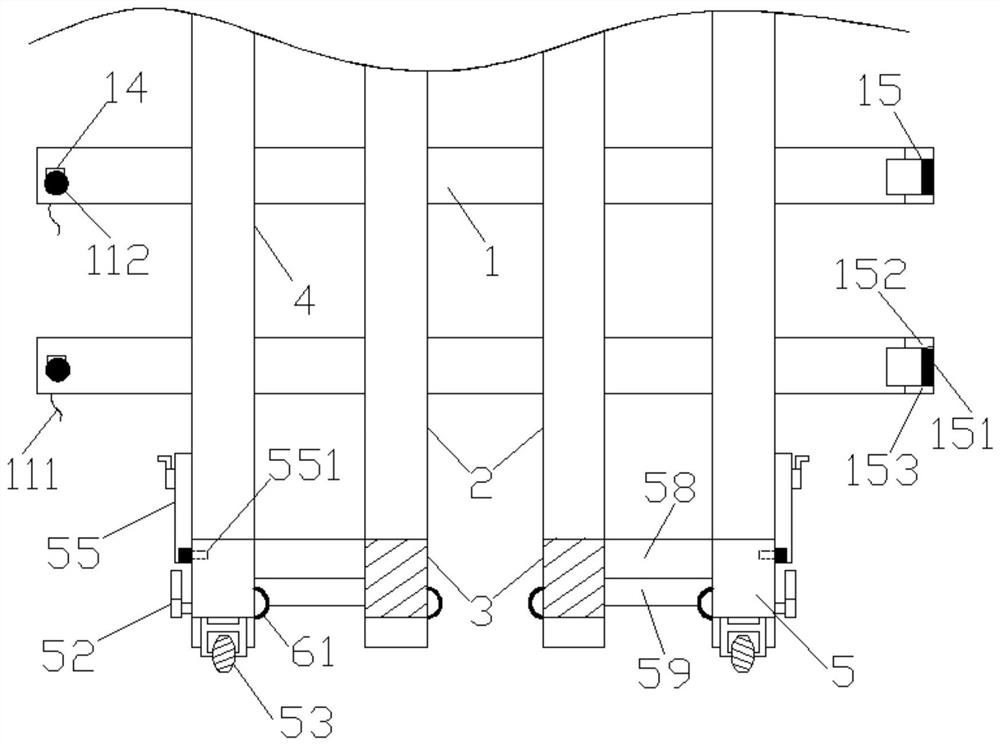

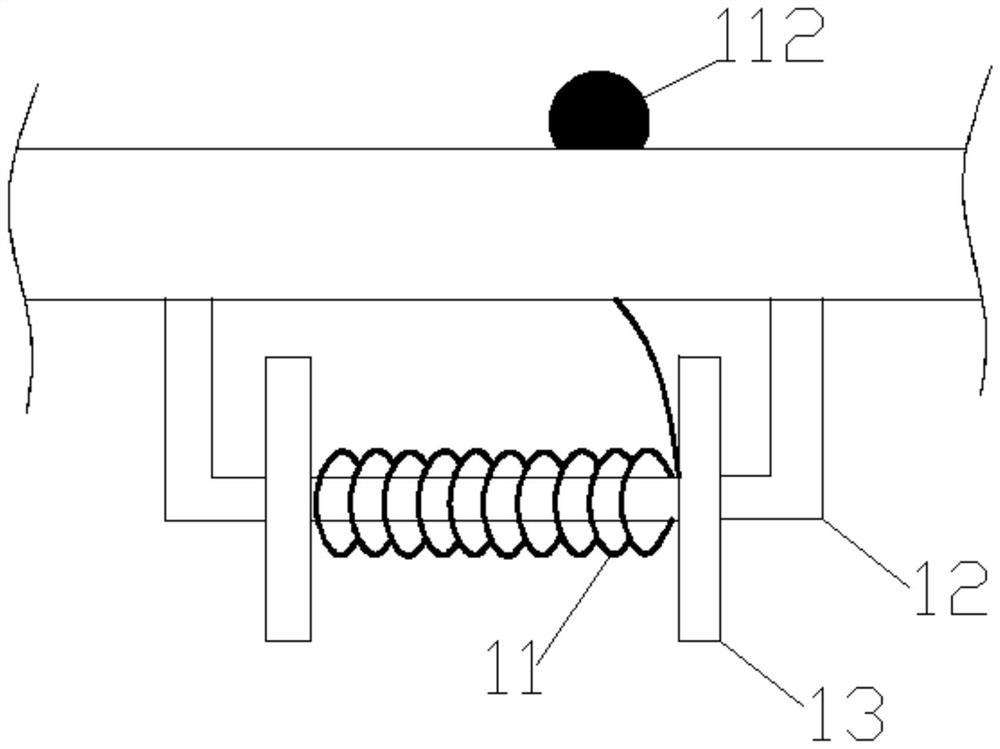

[0035] A loading and unloading fork for an industrial transport forklift, comprising a fork frame arranged in front of the forklift, the fork frame includes a positioning transverse plate 1, a positioning longitudinal plate 2, a positioning support plate 3, an extending longitudinal plate 4 and an extending bottom plate 5, and the positioning transverse Plate 1 is provided with No. 1 connecting rope 11, side end bracket 12, rotating shaft 13, through groove 14 and side end fixing sleeve 15, No. 1 connecting rope 11 is fixedly connected with rotating shaft 13, and No. 1 connecting rope 11 is provided with tail rope 111 And the tail knot ball 112, the diameter of the tail knot ball 112 is greater than the height of the through groove 14, the rotating shaft 13 is connected with the side end bracket 12 through the bearing, and the side end fixed sleeve 15 includes a vertical pole 151, an upper connection block 152 and a lower connection Block 153, the upper connecting block 152 is ...

Embodiment 3

[0038] A loading and unloading fork for an industrial transport forklift, comprising a fork frame arranged in front of the forklift, the fork frame includes a positioning transverse plate 1, a positioning longitudinal plate 2, a positioning support plate 3, an extending longitudinal plate 4 and an extending bottom plate 5, the positioning longitudinal The plate 2 is fixedly connected to the positioning transverse plate 1, the positioning support plate 3 is rotationally connected to the positioning longitudinal plate 2, the extending longitudinal plate 4 is slidingly connected to the positioning transverse plate 1, the extending bottom plate 5 is rotationally connected to the extending longitudinal plate 4, and the extending bottom plate 5 includes the bottom plate Main body 51, anti-skid bolt 52, universal wheel bracket 53, pull rod 54, No. Slidingly connected, the lifting rod 54 is rotationally connected with the bottom plate main body 51, the No. 1 horizontal bottom plate 58 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com