A bending machine with gear synchronous drive mechanism

A synchronous drive and bending machine technology, applied in the field of bending machines, can solve the problems of asynchronous drive, component wear, and difficulty for operators, and achieve the effects of avoiding swing, prolonging service life, and reducing maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to enhance the understanding of the present invention, the present invention will be described in detail below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not limit the protection scope of the present invention.

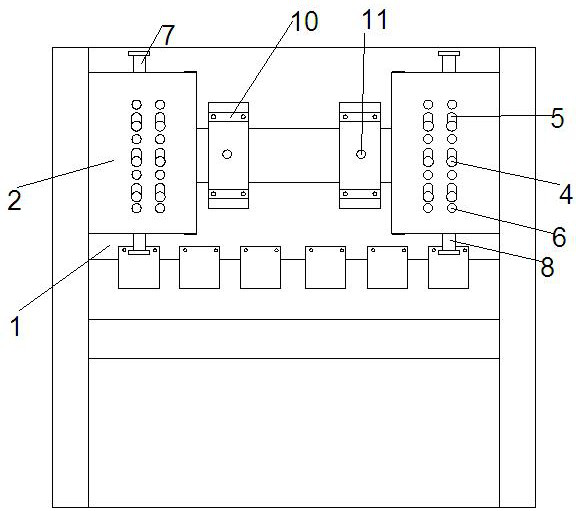

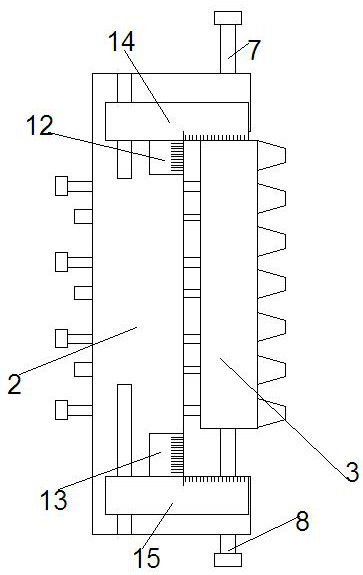

[0018] Such as Figure 1-3 As shown, the present invention is a bending machine with a gear synchronous drive mechanism, including a frame and a workbench. The frame on the workbench is provided with an upper frame 1 that drives the upper bending mold to move up and down. A fixed seat 2 parallel to the upper frame 1 is provided on both sides of the frame near the position of the upper frame 1, and a mounting groove is arranged on each fixed seat 2 opposite to the back of the upper frame 1. Two racks 3 They are respectively arranged in two installation grooves, several threaded holes are arranged on the rack 3, two vertical rows of fixed threaded holes are arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com