A device and method for laser shot peening composite rolling strengthening of a rotary body

A technology of laser peening and rotary body, applied in the field of surface deformation strengthening, can solve problems such as unapplicable, easy peeling of coating, uneven surface hardness and residual stress, etc., achieve uniform surface hardness and surface residual compressive stress, and improve roundness , the effect of reducing surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

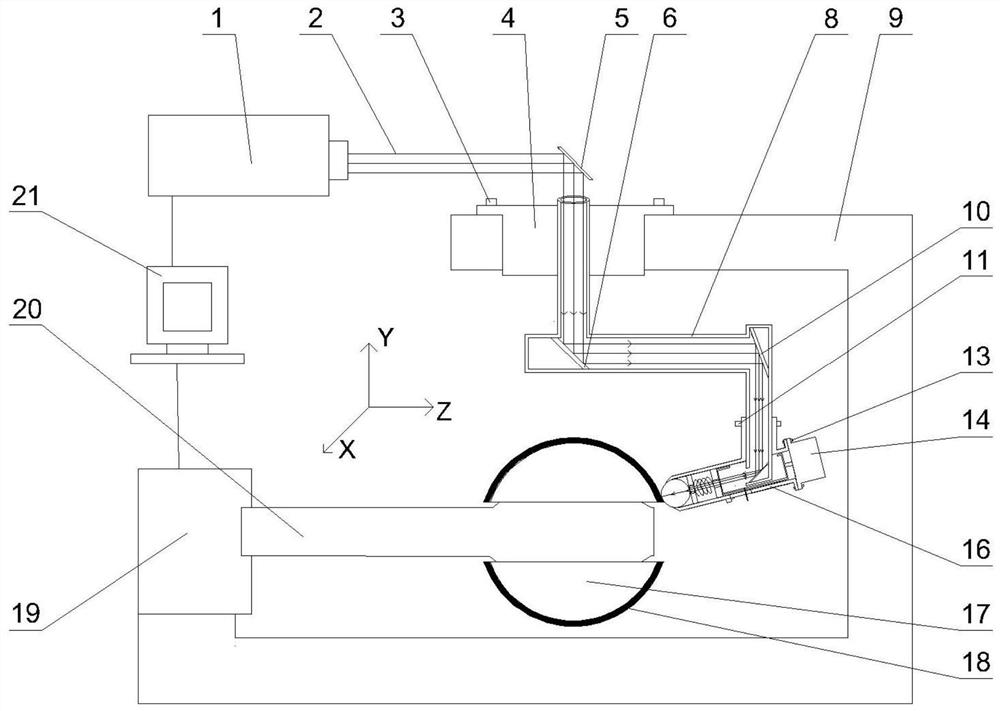

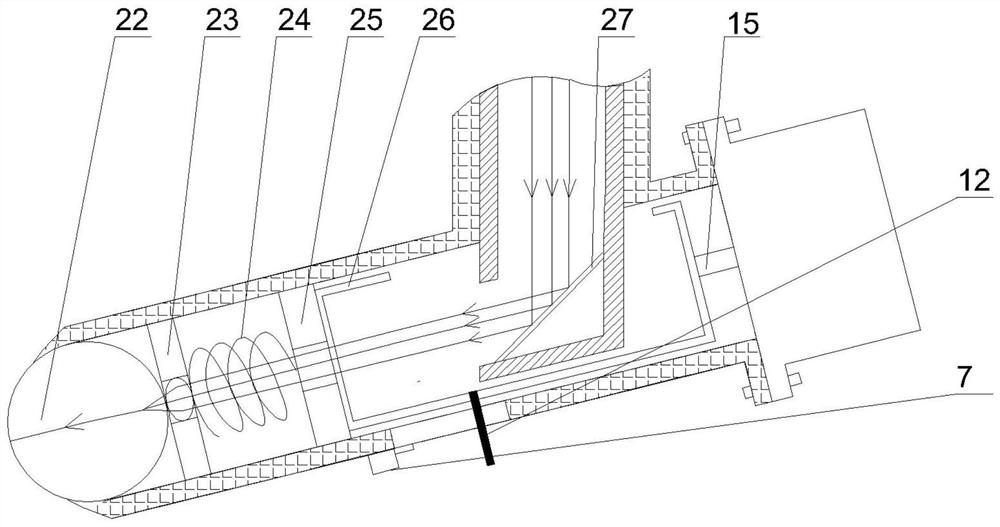

[0026] In the embodiment, take processing valve spheroid 18 as example, as figure 1 As shown, the laser shot peening composite rolling strengthening device of the rotary body of the present invention includes a laser emitting device 1, an optical path conveying device 8, a numerical control platform 9 and a rolling head 16; the laser emitting device 1 is used to produce Laser beam 2; one end of the optical path conveying device 8 is used to input the laser beam 2, and the other end of the optical path conveying device 8 is equipped with a rolling head 16, and the rolling head 16 is in contact with the valve spheroid 18 for making the laser beam 2 Through the rolling head 16, the surface of the valve ball 18 is laser peened and the surface of the rotary body is rolled and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com