Non-contact handheld multi-station automotive high-voltage ignition coil fault detector

A high-voltage ignition and coil failure technology, applied in engine ignition, spark ignition controller, machine/engine, etc., can solve problems such as high cost, failure to meet maintenance needs, failure to judge ignition coil, etc., to save time and cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Please refer to figure 1 , Embodiment 1 of the present invention is:

[0052] This embodiment is applicable to a scenario where a large component where the ignition coil is located fails, and is used to detect whether the ignition coil is working abnormally.

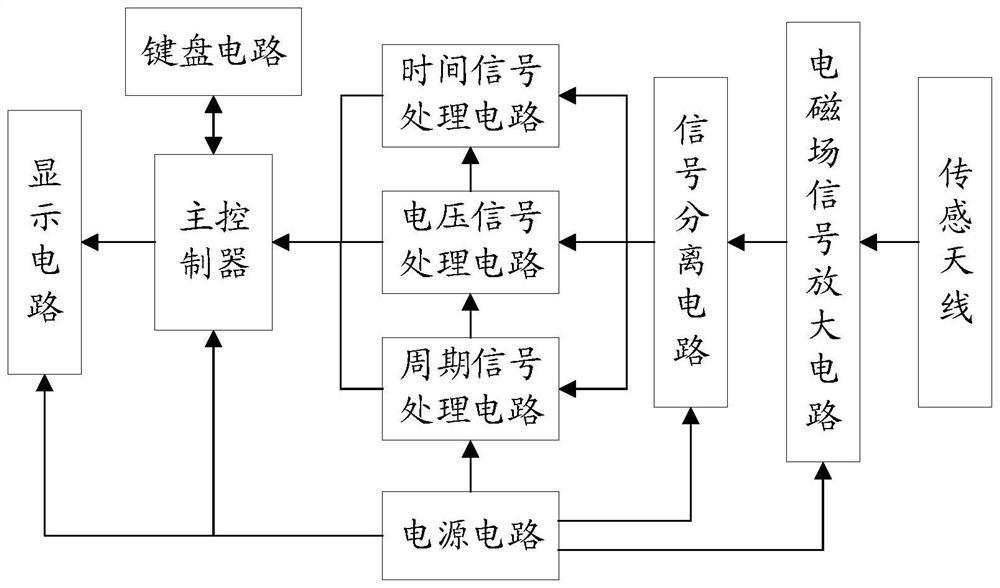

[0053] Non-contact handheld multi-station automotive high-voltage ignition coil fault detector, including power supply circuit, sensing antenna, electromagnetic field signal amplification circuit, ignition signal processing circuit, display circuit and keyboard circuit; output terminal of sensing antenna and electromagnetic field signal amplification circuit The input end of the electromagnetic field signal amplification circuit is connected to the input end of the ignition signal processing circuit, the output end of the ignition signal processing circuit is connected to the input end of the display circuit, and the ignition signal processing circuit is bidirectionally connected to the keyboard circuit, that is, ...

Embodiment 2

[0060] Please refer to Figure 1 to Figure 5 , the second embodiment of the present invention is:

[0061] This embodiment is applicable to a scenario where a large component where the ignition coil is located fails, and is used to detect whether the ignition coil is working abnormally.

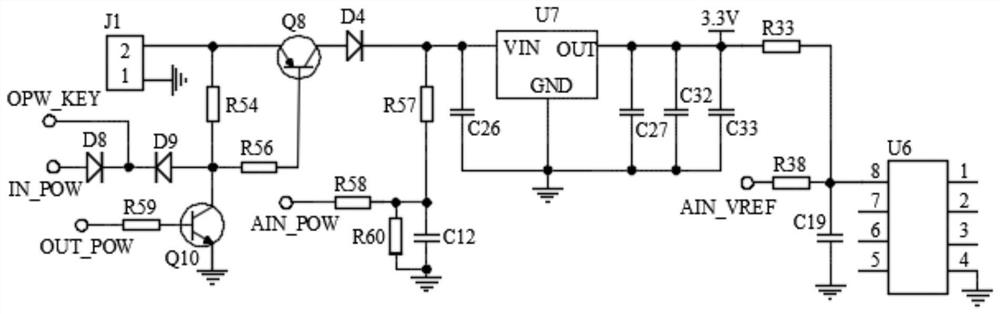

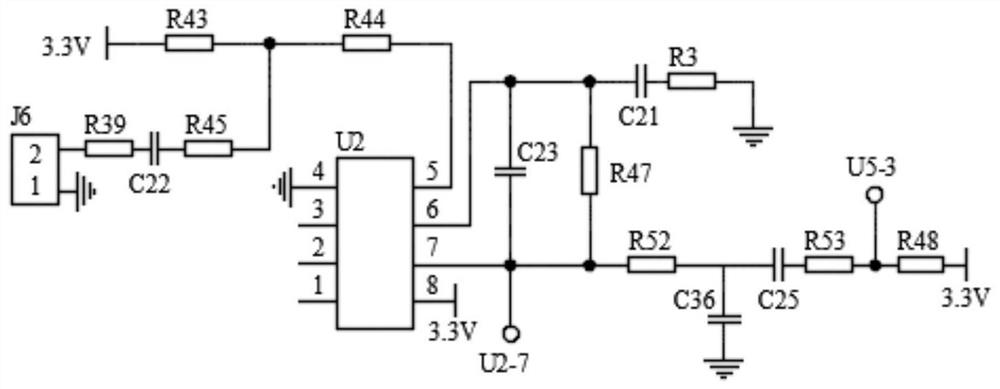

[0062] In the non-contact handheld multi-station automotive high-voltage ignition coil fault detector, on the basis of the first embodiment above, the signal processing circuit includes a main controller, a signal separation circuit, a voltage signal processing circuit, a time signal processing circuit and a period signal processing circuit The output terminal U2-7 of the electromagnetic field signal amplifying circuit is connected with the input terminal of the signal separation circuit, and the three output terminals of the signal separation circuit are respectively connected with the input terminal of the voltage signal processing circuit, the input terminal of the time signal processing c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap