Thread break detection device for thread guide tubes

A technology for wire breakage detection and wire passage, which is used in textiles, textiles, papermaking, looms, etc., can solve the problems that the rotating sheet cannot be completely reset, affecting production efficiency, and low production efficiency, and achieves long service life and production efficiency. High, timely alarm effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

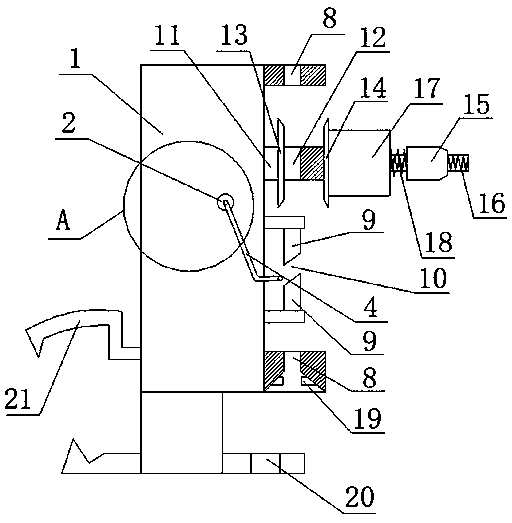

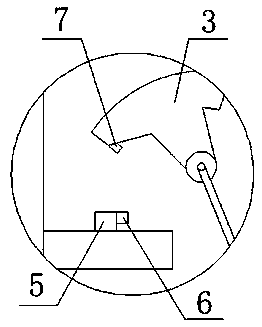

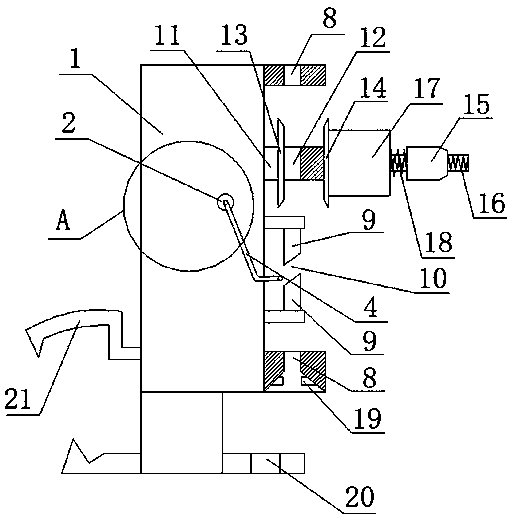

[0019] Example. A disconnection detection device for a line pipe, which is composed of figure 1 and 2 As shown, it includes a main body 1, and a rotating shaft 2 is installed in the main body 1; a rotating block 3 is fixed on one side of the rotating shaft 2, and a stop rod 4 is fixedly connected to the other side of the rotating shaft 2; Hall sensor 5 on the rotation path of 3, a magnet 6 is fixedly connected to one side of the Hall sensor 5; a metal block 7 is fixed at a position corresponding to the magnet 6 on the rotating block 3.

[0020] The mass of the rotating block 3 is equal to the quality of the stop bar 4; the upper and lower ends of the main body 1 on one side of the stop bar 4 are connected with wire slots 8, and the position between the two wire slots 2 is set There are two wire p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com