Distribution chute

A material distribution chute and discharge chute technology, which is applied in the field of material distribution chute, can solve the problems of high power consumption of electro-hydraulic push rods, difficulty in flipping the plate, and high production cost, so as to save driving power consumption and increase wear resistance. , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

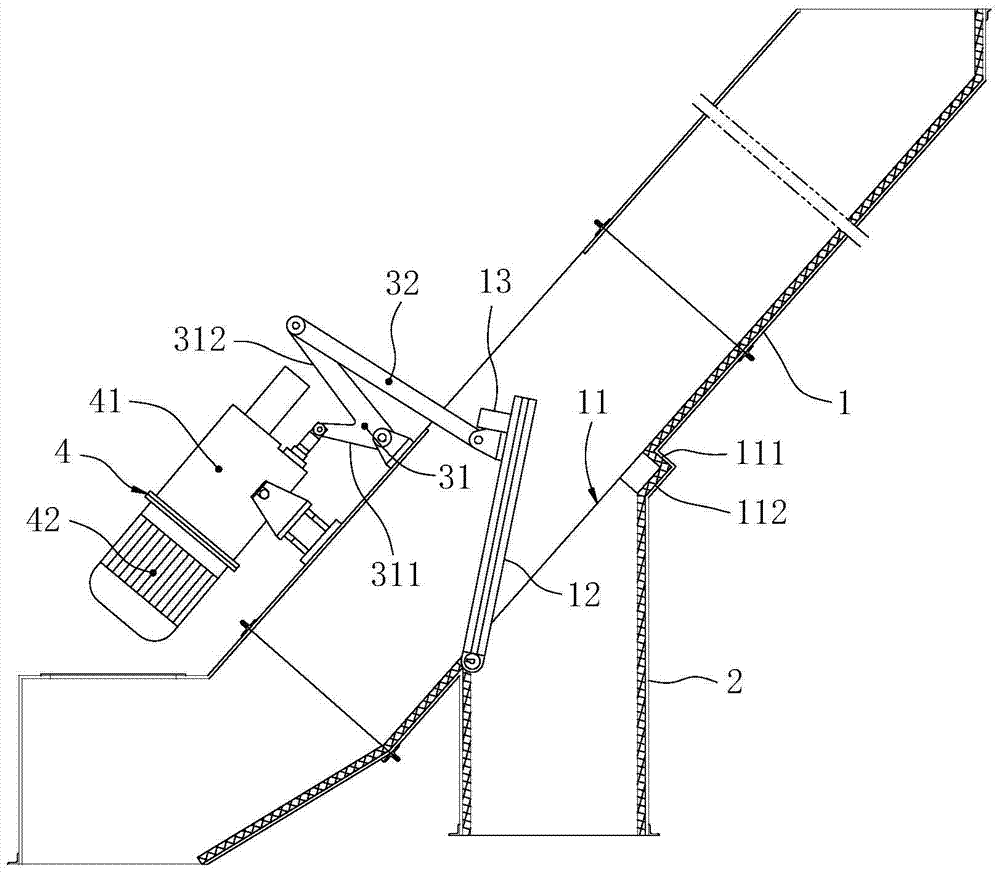

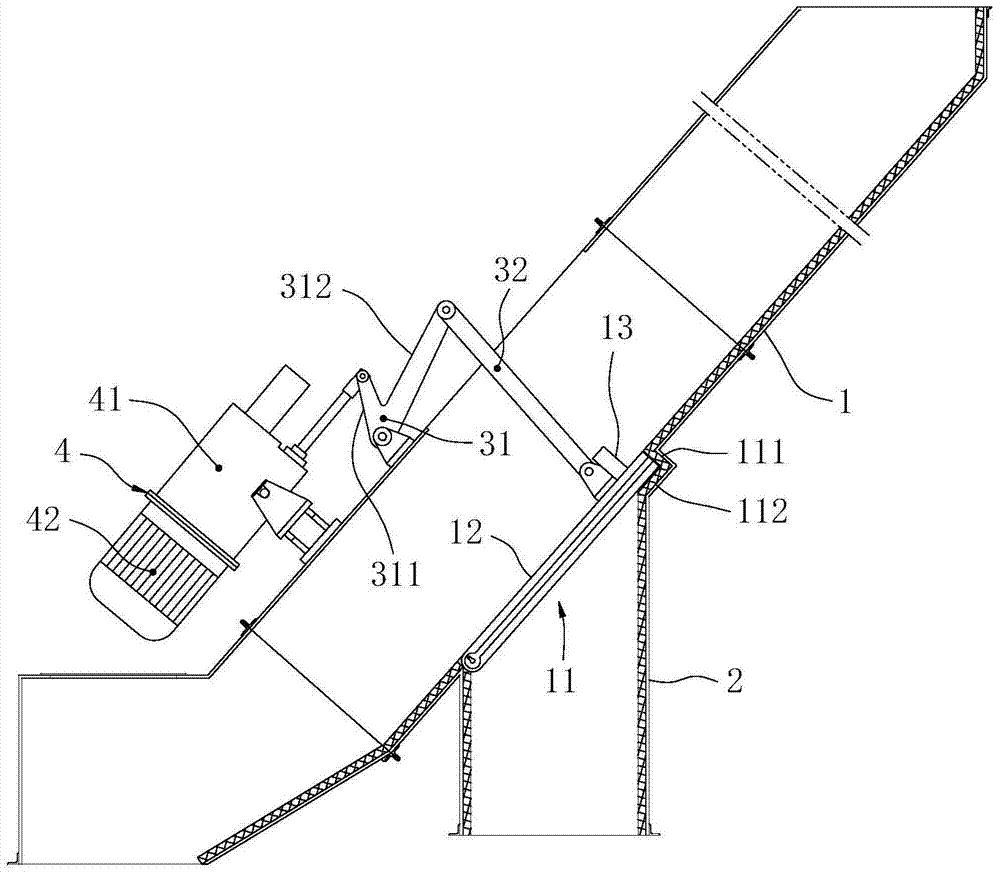

[0019] Such as figure 1 and figure 2 As shown, the distribution trough includes a main delivery chute 1 with a main discharge port at the lower end, an auxiliary discharge chute 2 arranged on the main delivery trough 1, a crank linkage mechanism and a driving mechanism 4; The opening 11 communicating with the auxiliary discharge chute 2 is provided with a flap 12, and the lower end of the flap 12 is rotationally connected with the main conveying trough 1; the rotational connection between the flap 12 and the main conveying trough 1 can be in various ways , for example: connected by hinge rotation, by pin rotation or by rotation shaft rotation; Under the driving action of driving mechanism 4, can drive turning plate 12 to turn over around the rotating connection position of turning plate 12; Turning plate 12 turns over and can open or close opening 11; Driving mechanism 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com