Movable lifting machine device capable of being cascaded in groups and control method thereof

A control method and lift technology, applied in lifting devices, mobile jacks, etc., can solve problems such as poor adaptability of lifts, inconvenience for maintenance companies, limited lifting weight of lifts, etc., and achieve the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

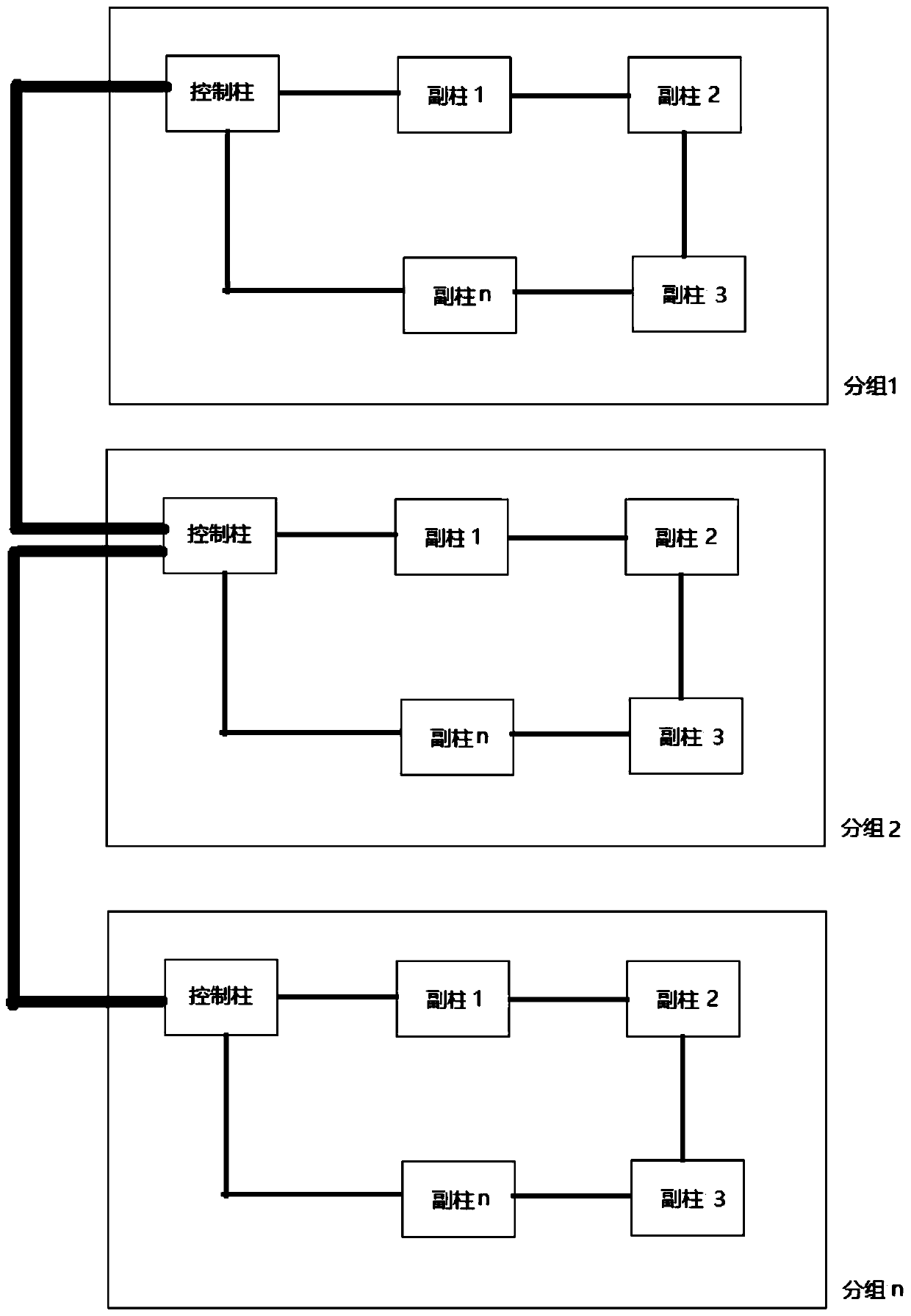

[0032] See attached figure 1 , a mobile lift device that can be grouped and cascaded, including several groups, each group is provided with several lifting columns, and the lifting columns in each group include a main control column and n auxiliary columns ;

[0033] The main control column in each group establishes a communication connection with all the auxiliary columns in the group through communication cables or wirelessly, and the auxiliary column is responsible for collecting the height and key information of the auxiliary column and sending them to the main control column in the group. The main control column controls the operation of all lifting columns in the same group according to the summarized information;

[0034] The lifting columns work based on the motor-hydraulic method. Each lifting column includes a control module, a position sensor and a button; the main control column can set the working mode of the lifting column in this group as single column, local c...

Embodiment 2

[0038] The control method adopted by a mobile lift device that can be grouped and cascaded described in Embodiment 1 includes the following steps:

[0039] (1) Group setting: Group setting is performed when a mobile lift device that can be grouped and cascaded leaves the factory, and the lifting columns in each group are numbered;

[0040] (2) Set the mode through the main control column in each group: when it is set to the single column mode, the button of a certain lifting column can only control the lifting of the lifting column; when it is set to the group mode, any lifting column The buttons of the lifting column can control the lifting of the lifting column; when it is set to the cascade mode, the buttons of any lifting column in the cascading group can control the lifting columns in all groups to perform synchronous lifting;

[0041] (3) Determination of the total control column in different modes: in single column mode, the total control column is the single lifting co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com