Cargo sorting task allocation method and device

A distribution method and technology of goods, applied in the field of logistics, can solve problems such as inflexible picking operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0107] In order to make the above objects, features and advantages of the present application more obvious and comprehensible, the present application will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods.

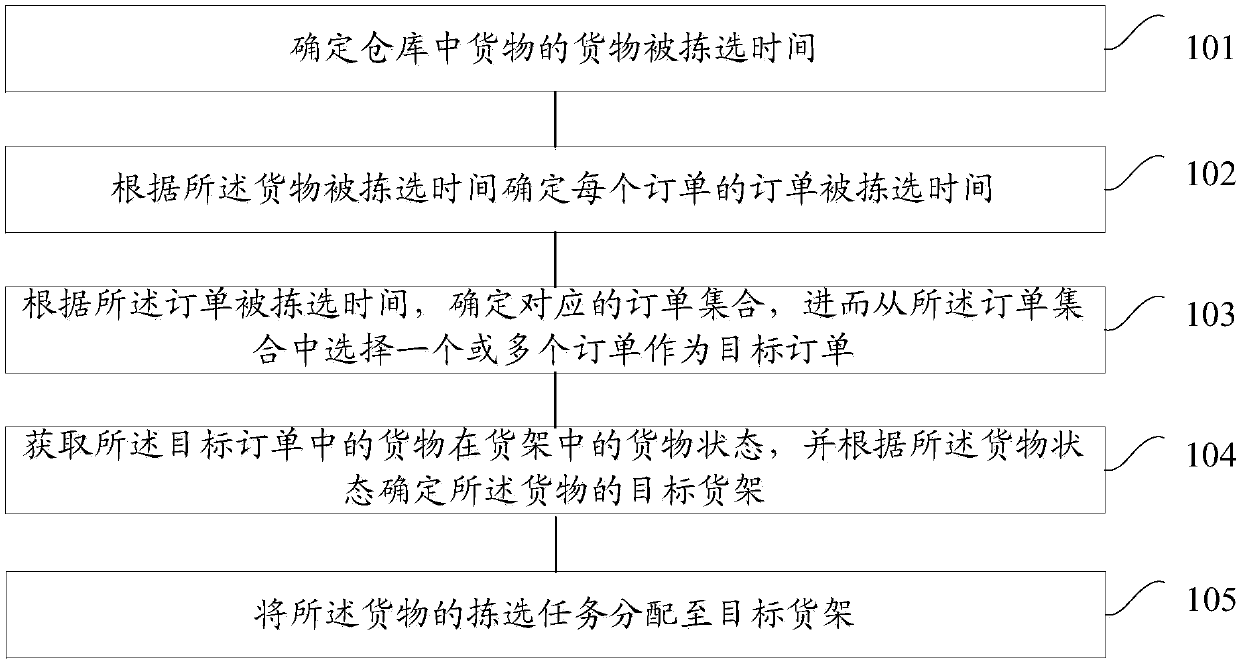

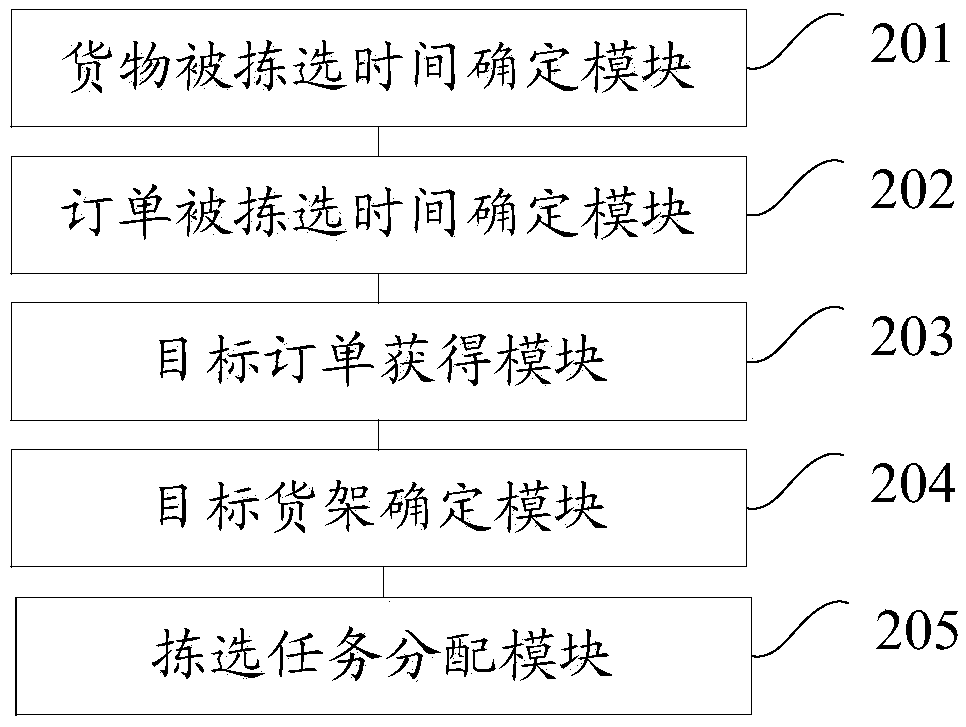

[0108] refer to figure 1 , which shows a flow chart of the steps of an embodiment of a method for assigning goods picking tasks of the present application, which may specifically include the following steps:

[0109] Step 101, determine the time when the goods in the warehouse are picked.

[0110] The embodiment of the present application can be applied to an automated high-density warehouse. Specifically, an automated high-density warehouse refers to an automated storage system in which shelves are arranged closely adjacent to each other and goods are stored and picked.

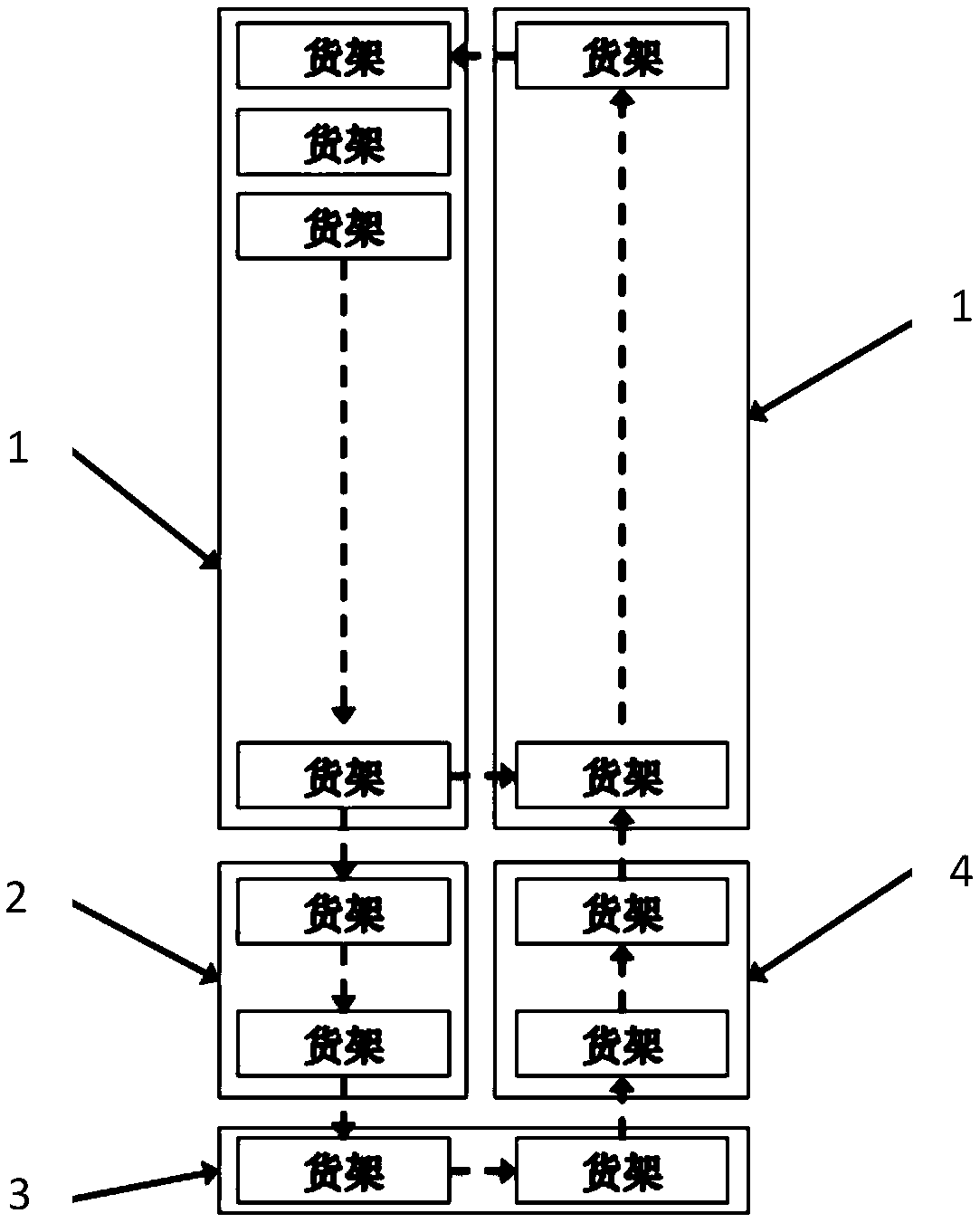

[0111] refer to figure 2 , which is a partial structural schematic diagram of an automated high-density warehouse of the present a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com