Robot intelligent maintenance prompt management method

A technology of robot intelligence and management methods, which is applied in the field of robot intelligent maintenance prompt management, can solve the problems of differentiated maintenance requirements, low overall efficiency, and inability to manage uniformly, and achieve the effect of guaranteeing production and operation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below according to the accompanying drawings.

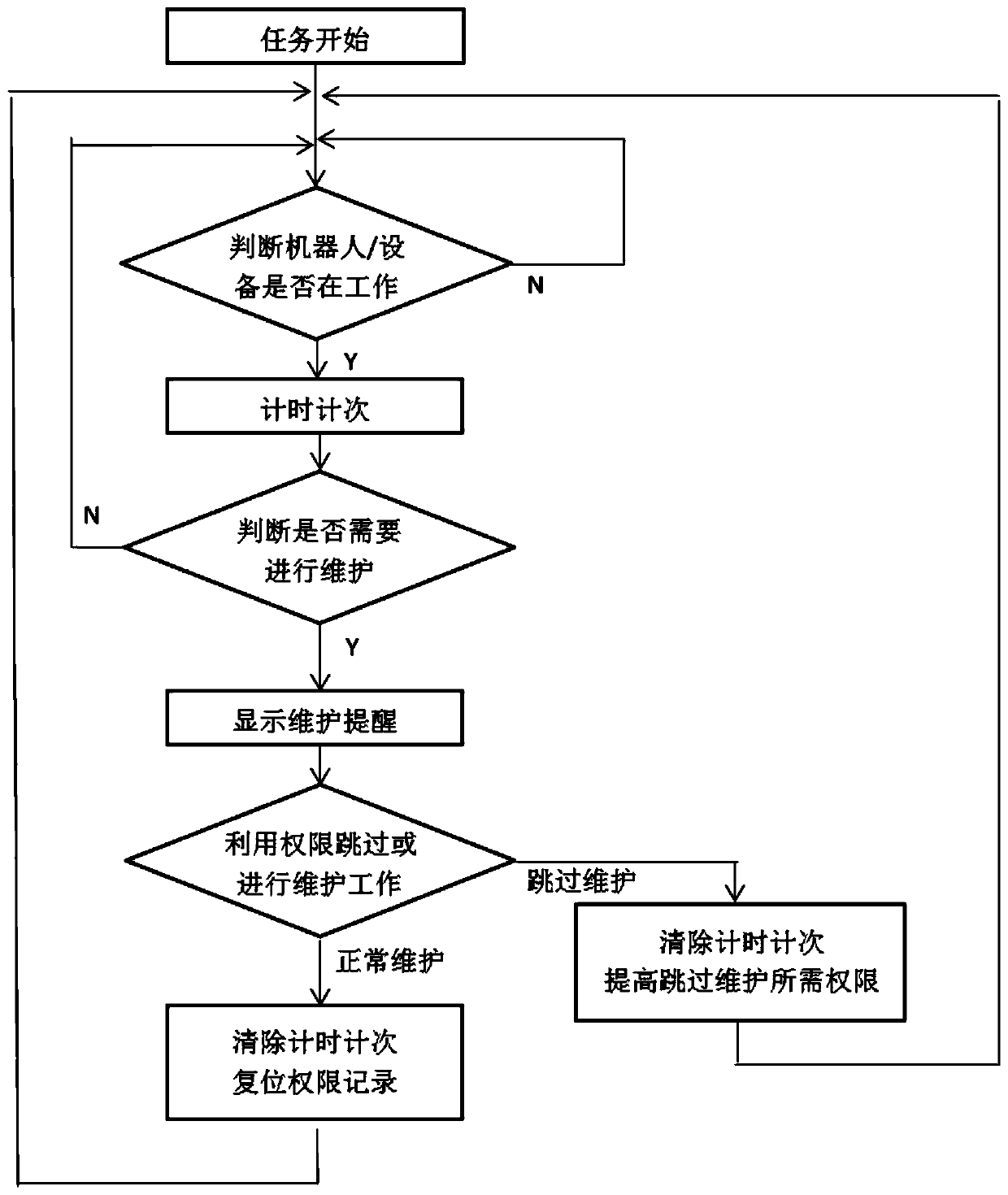

[0021] like figure 1 As shown, a robot intelligent maintenance prompt management method, the specific method is as follows:

[0022] (1) Set the timers and counters in the PLC according to the maintenance items of each robot / equipment in the project; set the values of each timer and counter according to the corresponding maintenance requirements; and enter the Reminder alarms and maintenance operation instructions for each maintenance item, and show how much time / working times there is until the next maintenance through calculation;

[0023] (2) Enter the authority password of different operation authority;

[0024] (3) According to the operating status of the robot / equipment, let each timer count and the counter count;

[0025] (4) When a certain timer / counter reaches the specified value, trigger the reminder state of the corresponding maintenance work, and display the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com