Edge covering machine equipment

An edge wrapping machine and edge wrapping technology, applied in the direction of mechanical processing/deformation, can solve problems such as low efficiency and unguaranteed edge wrapping effect, and achieve the effects of neat and consistent appearance, improved stability and consistency, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

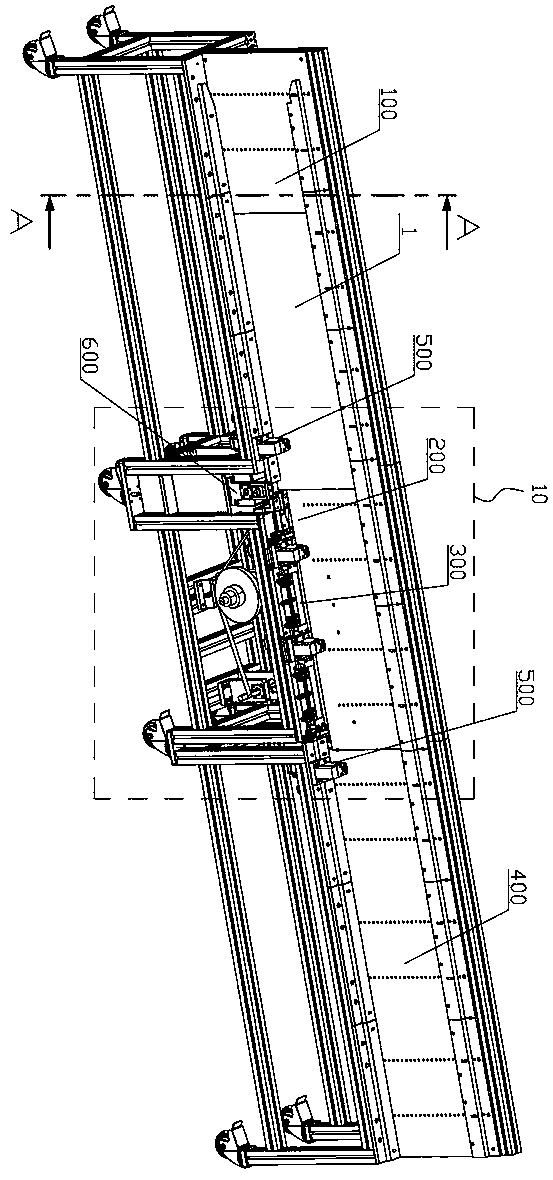

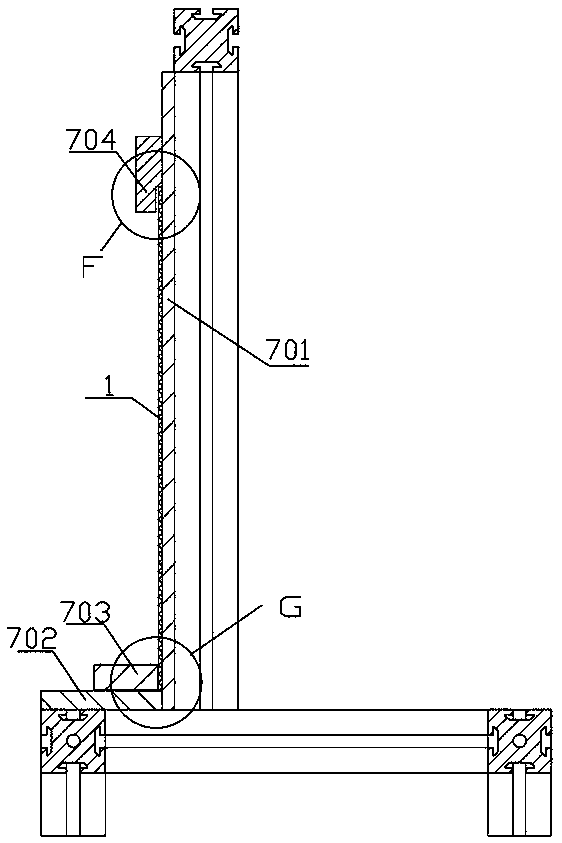

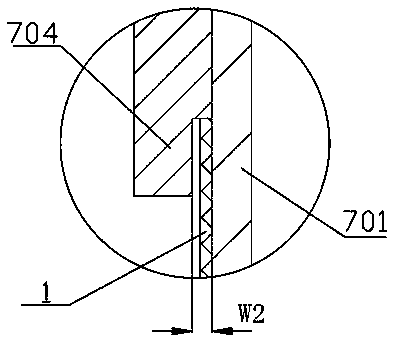

[0038] see Figure 1~Figure 19 , the embodiment of the present invention provides an edge wrapping machine for edge wrapping a sheet product 1 . The sheet product 1 is, for example, thermal insulation cotton with a thickness of about 3-5 mm, and the thermal insulation cotton is wrapped with the soft edge wrapping material 2 . The edge-wrapping soft material 2 is made of flexible material, which may be polyimide (PI). The width of the edge-wrapping soft material 2 is greater than the thickness of the sheet-like product 1 , for example, the sheet-like product 1 has a thickness of about 3-5 mm, and the edge-wrapping soft material 2 has a width of 20 mm.

[0039] Such as figure 1 As shown, the hemming machine equipment includes a feeding mechanism, a hemming mechanism 200 , a curing device 300 , and a receiving station 400 . Wherein, the hemming mechanism 200 includes a bonding area and a flanging area arranged in sequence.

[0040] The sheet product 1 moves smoothly along a s...

Embodiment 2

[0073] Different from Embodiment 1, in this embodiment, the edge-wrapping soft material is a product without an adhesive layer itself, such as a cloth tape (belt-shaped cloth). Because the cloth tape itself does not have an adhesive layer, it is necessary to apply glue to the cloth tape before feeding it to the hemming mechanism, so that one side of the cloth tape is coated with an adhesive layer. The wrapping shaft can manually adjust the tension of the cloth tape.

[0074] Place the roll-shaped cloth tape on the packaging material shaft, and the cloth tape is pulled out from the packaging material shaft, and after passing through the second set of guide wheels, it is glued out of the gluing assembly, and the first glue layer is formed on one side. Afterwards, the tape passes through the first set of guide wheels and is placed at the bell mouth. Because the gluing assembly of this embodiment is used for gluing the cloth tape, the position of the gluing assembly of this embod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com