Blade opening and closing mechanism based on rotary flapping wing vertical take-off and landing power device

A power device and vertical take-off and landing technology, applied in the aerospace field, can solve the problems of low efficiency, high cost, no ascending, descending and hovering, etc., and achieve the effect of simple structure, low cost, and not easy to couple interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

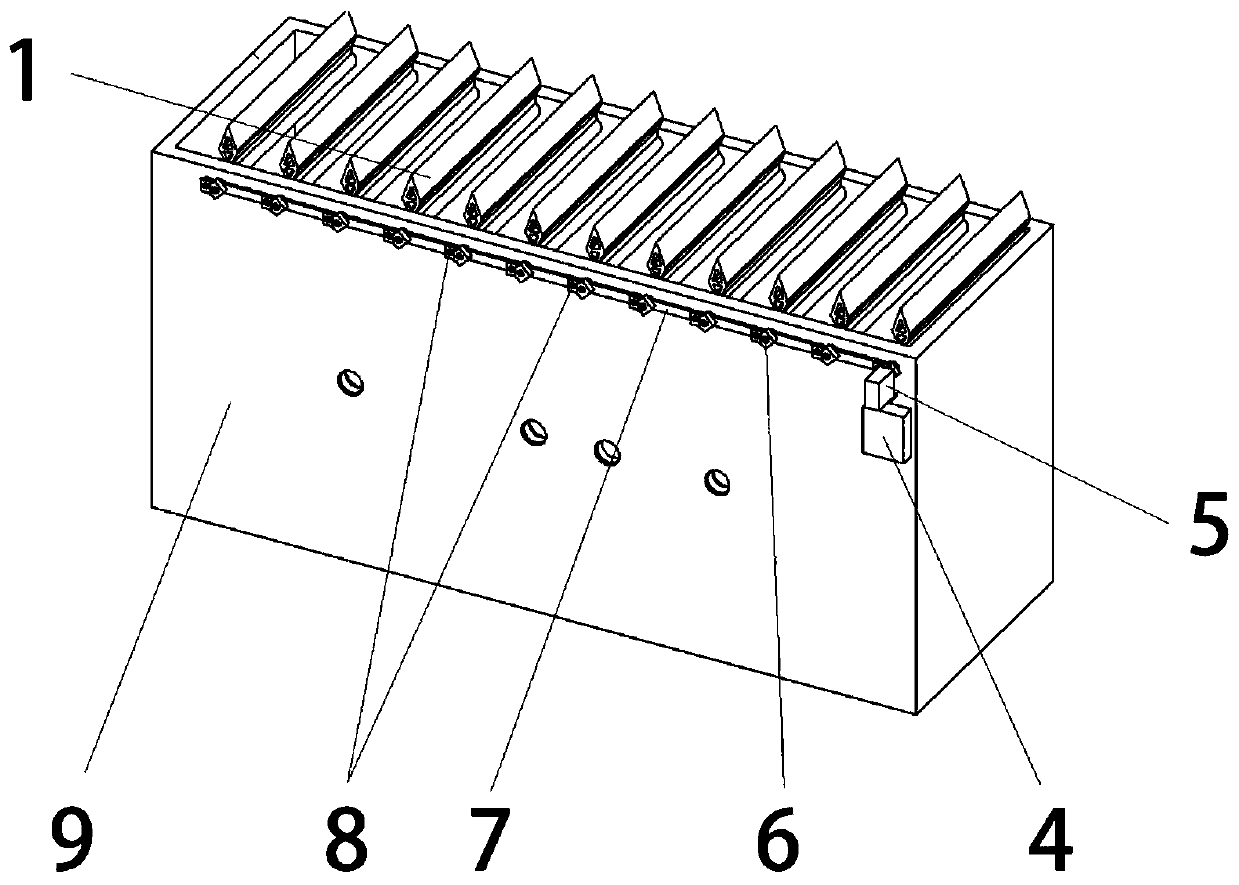

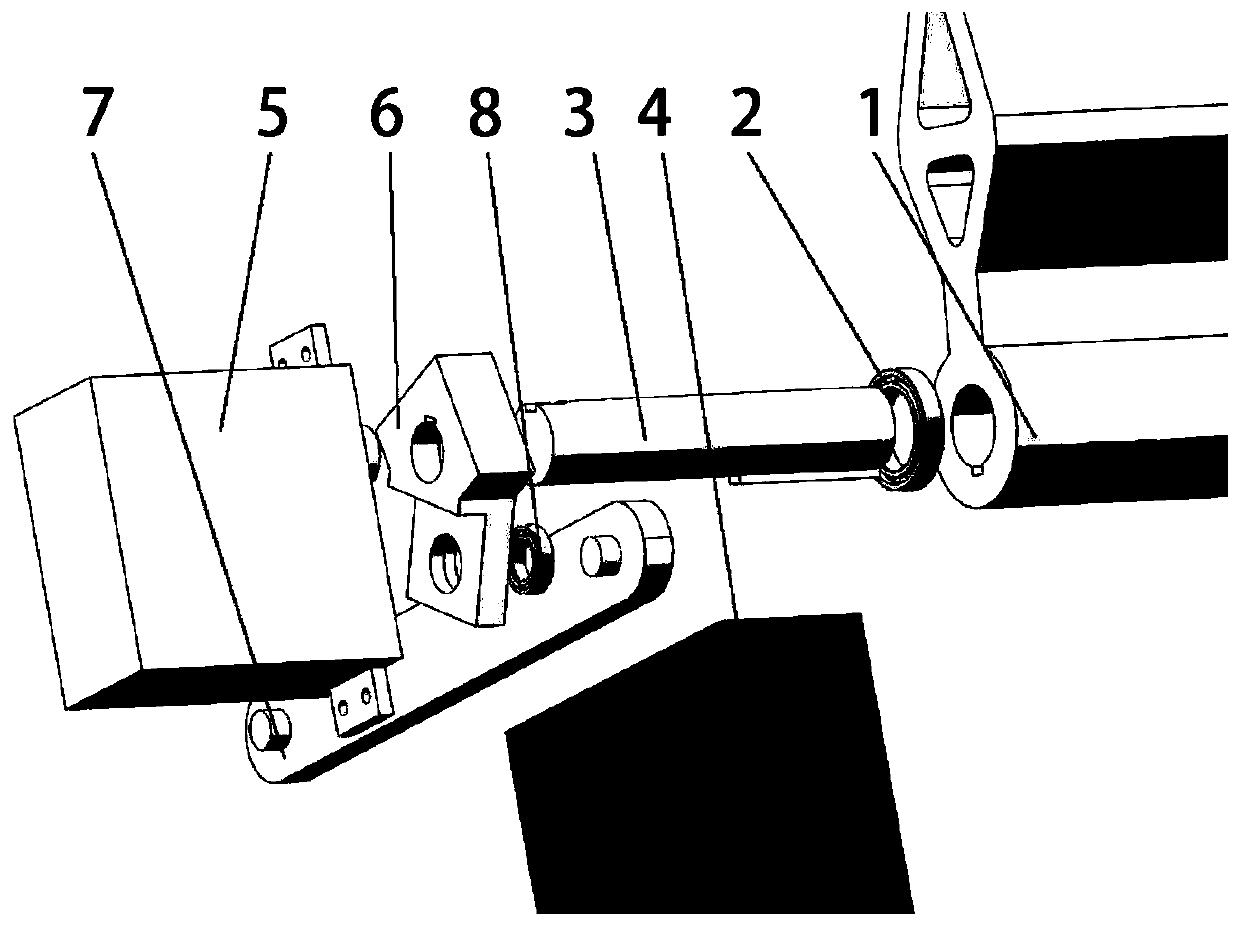

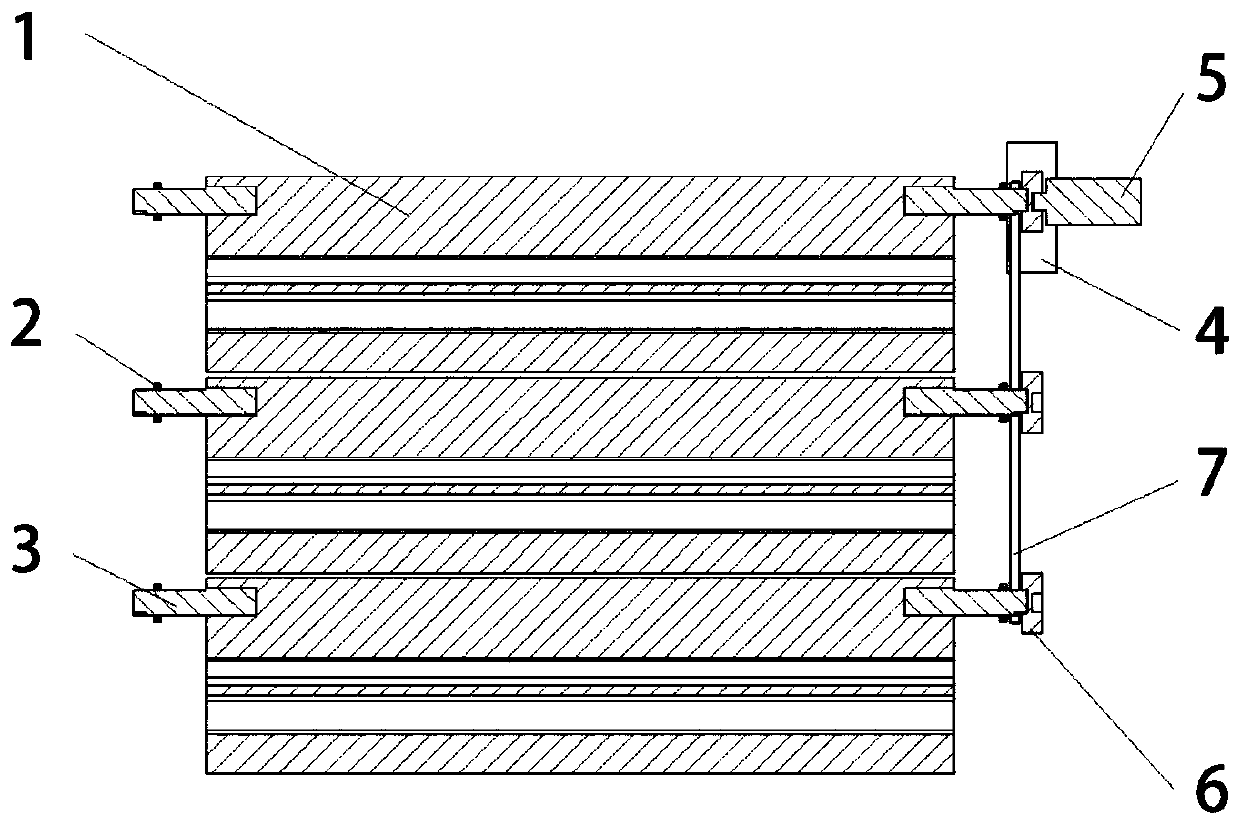

[0020] The present invention includes a blade 1, a large bearing 2, a connecting shaft 3, a control system 4, a steering gear 5, a steering head 6, a linkage rod 7, and a small bearing 8. The blade 1 is a "drop-shaped" head and a circular The section formed by the tail is a long strip of lightweight aluminum strip stretched. The "drop-shaped" head of the cross-section of the blade 1 is hollowed out in the middle to reduce the overall mass and improve rigidity. The "water drop" of the blade 1 There should be at least 1 cm gap between the shaped head and the rounded tail of the adjacent leaf. The cylindrical tail of the cross-section of the blade 1 is solid in the middle of the axis, and there are "concave" holes on both sides for connecting with the connecting shaft 3. The connecting shaft 3 is a "convex"-shaped column at the head and a cylindrical tail. Comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com