A grinding head offline testing platform and method

A test platform and grinding head technology, which is applied in the direction of measuring the growth and deceleration rate of the fluid, using liquid/vacuum degree to measure the liquid tightness, etc., can solve the problems of material waste, reduce the measurement area and increase the accuracy of the measurement , the effect of increasing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030]The following will be combined with the accompanying drawings in the embodiments of the present invention, the technical solution in the embodiments of the present invention will be described clearly and completely, it is clear that the embodiments described are only a part of the embodiment of the present invention, not all embodiments.

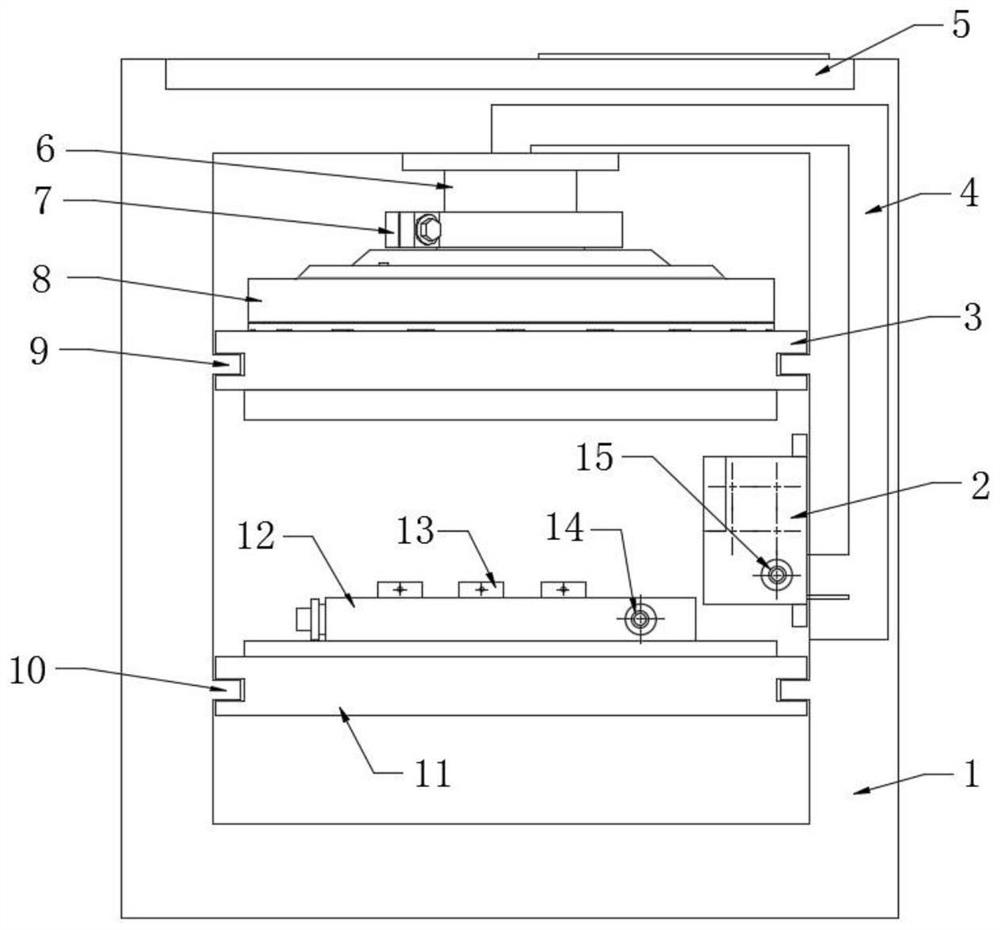

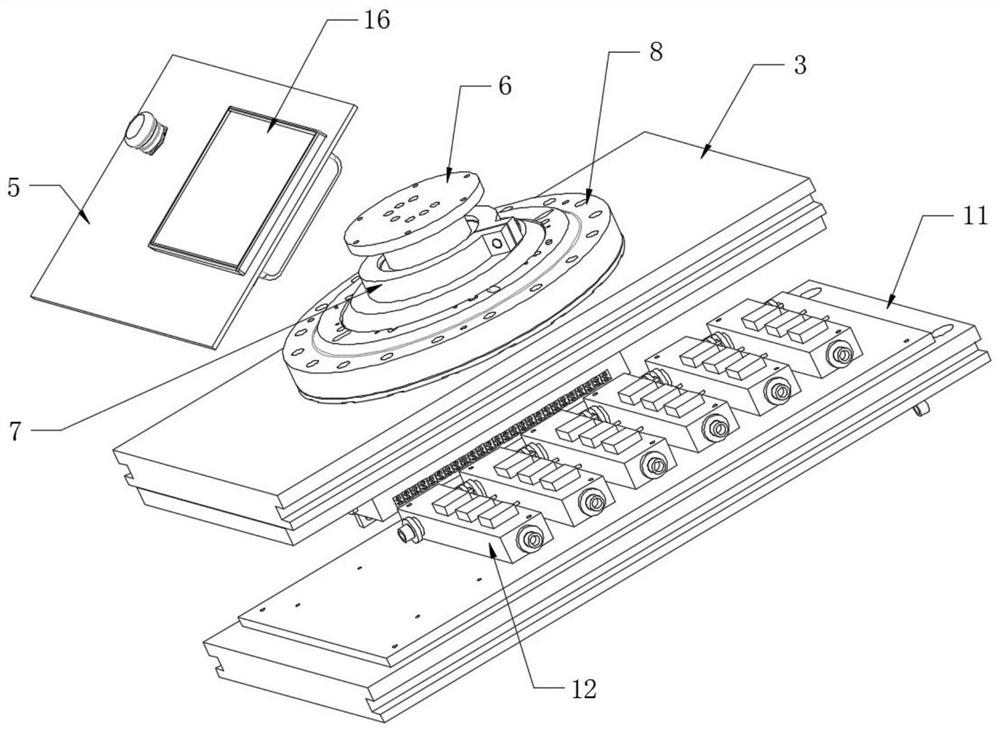

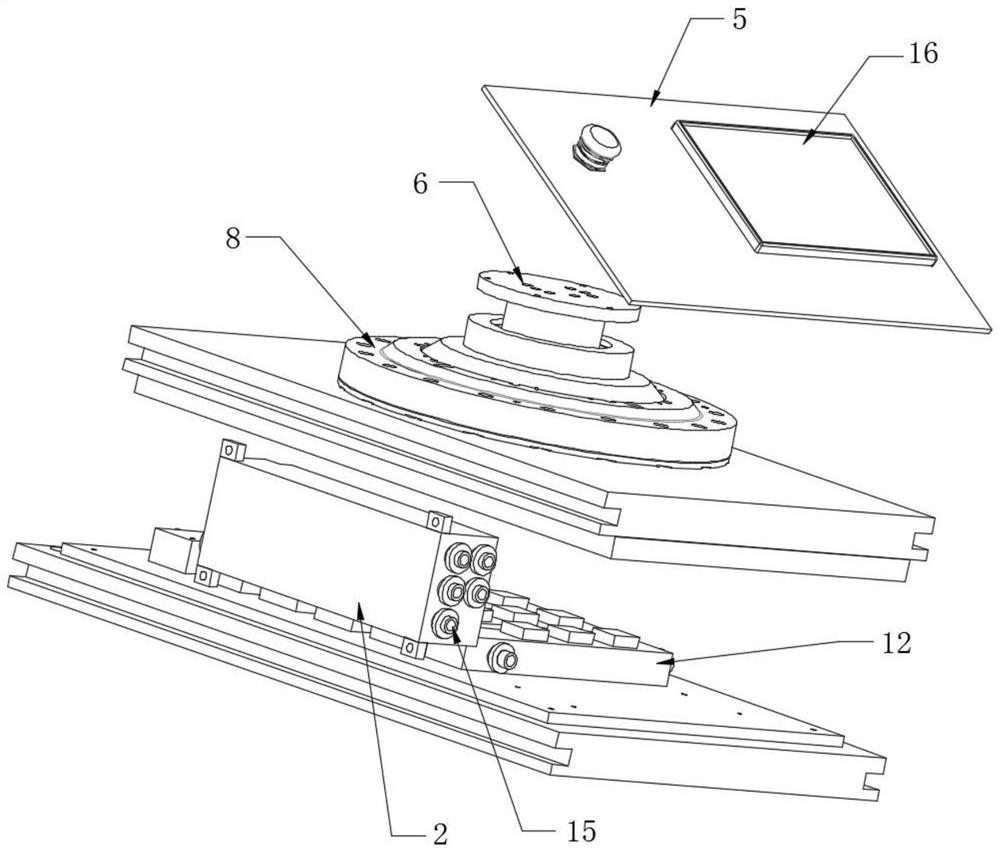

[0031] Reference Figure 1-3 , an offline test platform of grinding head, including control box 1, control box 1 is installed with an actuator and testing mechanism, the inner side wall of the control box 1 is symmetrically installed with two first card boards 9 and two card boards 10, two first card boards 9 and two second card boards 10 are sliding inserted with the first plate 3 and the second plate 11, the actuator is installed on the first plate 3, the detection mechanism is installed on the second plate 11.

[0032] The actuator is divided into pneumatic connector 6, metal headband 7 and grinding head 8 from top to bottom.

[0033] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com