A self-sealing micro-nanofluidic chip processing method

A technology of micro-nano fluidic control and processing method, which is applied in the direction of chemical instruments and methods, laboratory containers, laboratory utensils, etc., which can solve the problems of unstable structure, small amount of liquid sample and airtightness, etc., and achieve good airtightness Good sealing performance and high structural precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

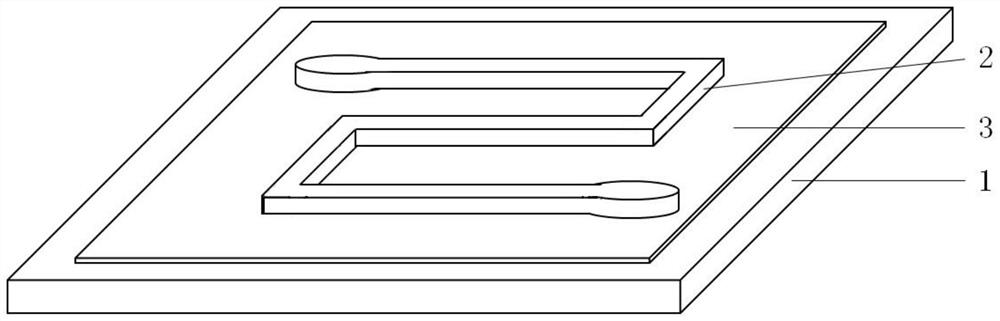

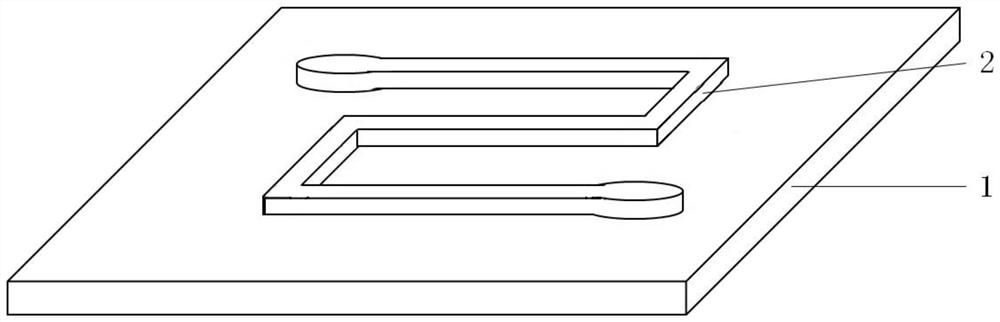

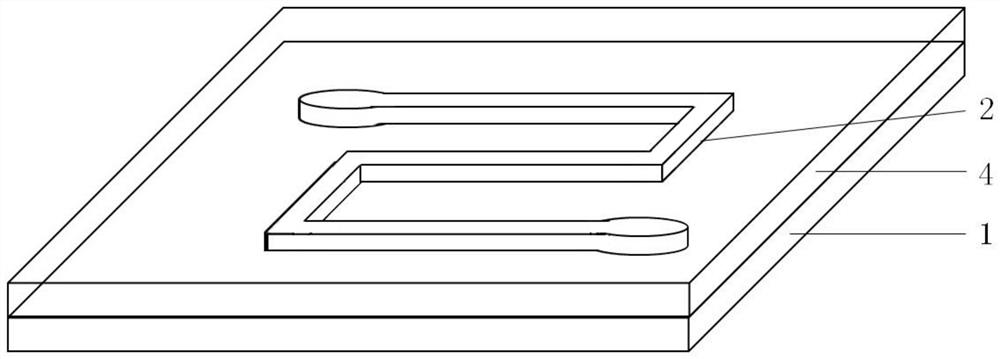

Image

Examples

Embodiment 1

[0031] To make a self-sealing nanofluidic chip by using the method described in the present invention, the specific steps are as follows:

[0032] 1. Spin-coat a layer of embossing glue on a 6-inch glass wafer, press the existing mold into the embossing glue with nano-imprinting equipment, and the embossing glue is cured after ultraviolet exposure, and then the mold and the cured embossing glue are combined Printing glue separation. In this way, the negative structure on the mold is transferred to the embossing glue, forming the desired nano-flow channel structure composed of the imprinting glue.

[0033] The specific parameters are as follows:

[0034] Spin coating revolutions of embossing glue 5000 rpm Imprint adhesive spin coating time 40 seconds UV exposure time 30 seconds

[0035] 2. Remove the residual layer of imprinting glue by reactive ion etching (RIE).

[0036] The specific parameters are as follows:

[0037] BCl3 gas flow...

Embodiment 2

[0046] A self-sealing microfluidic chip is manufactured by the method of the present invention, and the specific steps are as follows:

[0047] 1. Spin-coat a layer of photoresist on a 6-inch glass wafer, and expose it on a photolithography machine through a photolithography plate. There are patterns of micro-channels on the photolithography plate, and the pattern is opaque and other places are light-transmitting. The glass with photoresist is rinsed in the developer solution, and the photoresist is washed away in the exposed place, leaving only the microchannel structure composed of photoresist.

[0048] The specific parameters are as follows:

[0049] Photoresist spin coating revolutions 3000 rpm Photoresist Spin Time 40 seconds UV exposure time 10 seconds

[0050] 2. Use plasma stripping to remove residual glue.

[0051] The specific parameters are as follows:

[0052] Oxygen flow rate 100 sccm Nitrogen flow rate 30 sccm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com