Air suction assembly and fastening tool with air suction assembly

A component and fastening technology, applied in the field of screwdriver equipment, can solve the problems of inability to use magnetic adsorption, inconvenient access to non-magnetic screws, etc., and achieve the effect of improving inconvenient access and inability to use magnetic adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

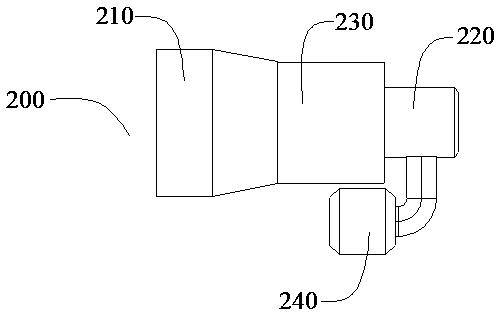

[0029] An air suction assembly 200 has a main casing capable of being connected to a vacuum source, the main casing has a first connecting section 210 and a second connecting section 220, the main casing is connected with the power part 100 through the first connecting section 210, the main casing The housing is connected with the fastening part 300 through the second connection section 220 .

[0030] Between the first connecting section 210 and the second connecting section 220 of the main housing is a hollow connecting section 230 , and the first connecting section 210 , the intermediate connecting section 230 and the second connecting section 220 are integrally formed.

[0031] The side of the main housing has a vacuum air joint 240 that can be connected to a vacuum source. The vacuum air joint 240 is sealed and connected to the vacuum source through a connecting air pipe. The vacuum source can apply vacuum suction pressure to the inner cavity of the main housing.

[0032] ...

Embodiment 2

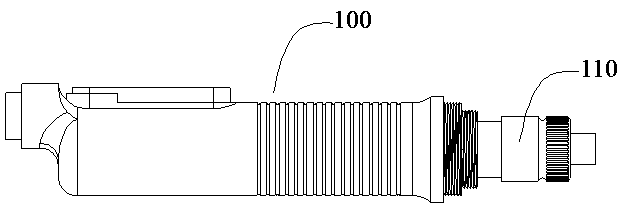

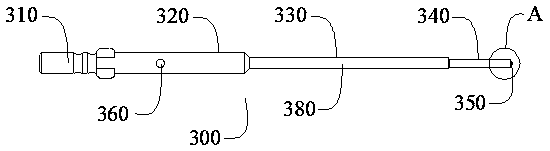

[0042] A fastening tool includes a power part 100 , a fastening part 300 and an air suction assembly 200 , one end of the air suction assembly 200 is fixedly connected with the power part 100 , and the other end of the air suction assembly 200 is fixedly connected with the fastening part 300 .

[0043] The suction assembly 200 has a main housing that can be connected to a vacuum source. The main housing has a first connecting section 210 and a second connecting section 220. The main housing is connected to the power part 100 through the first connecting section 210. The main housing is connected to the power part 100 through the first connecting section 210. The second connection section 220 is connected with the fastening part 300 .

[0044]Between the first connecting section 210 and the second connecting section 220 of the main housing is a hollow connecting section 230 , and the first connecting section 210 , the intermediate connecting section 230 and the second connecting...

Embodiment 3

[0058] An electric screwdriver, including an electric screwdriver 100' for outputting power and a screwdriver head 300' connected to the front end of the electric screwdriver 100' for absorbing fastening screws. There is an air suction between the electric screwdriver 100' and the screwdriver head 300' Component 200.

[0059] The suction assembly 200 includes a main housing, the main housing has a first connection section 210 fixedly connected to the shell of the electric batch 100' and a second connection section 220 fixedly connected to the bit 300', the first connection section 210 and the second connection section 210 There is a hollow connecting section 230 between the two connecting sections 220 .

[0060] The side of the main housing has a vacuum air joint 240 that can be connected to a vacuum source. The vacuum air joint 240 is sealed and connected to the vacuum source through a connecting air pipe. The vacuum source can apply vacuum suction pressure to the inner cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com