Monorail conveyor

The technology of a monorail conveyor and a nose is applied to the monorail conveyor and the traction of the monorail conveyor. It can solve the problems of low safety of monorail conveyors, backslide of monorail conveyors, poor braking effect of monorail conveyors, etc., and achieve the effect of improving braking effect, good braking effect, and improving use safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

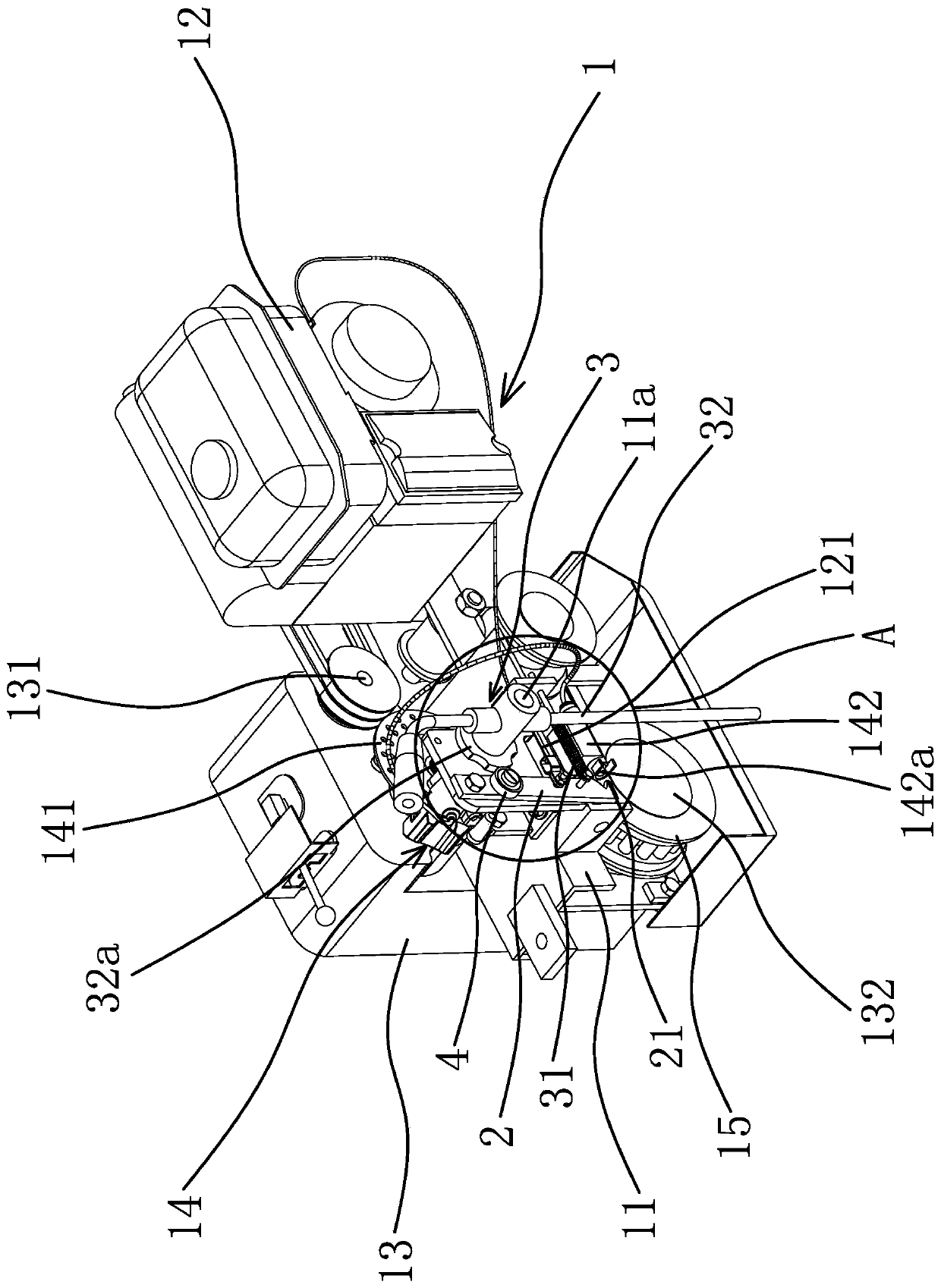

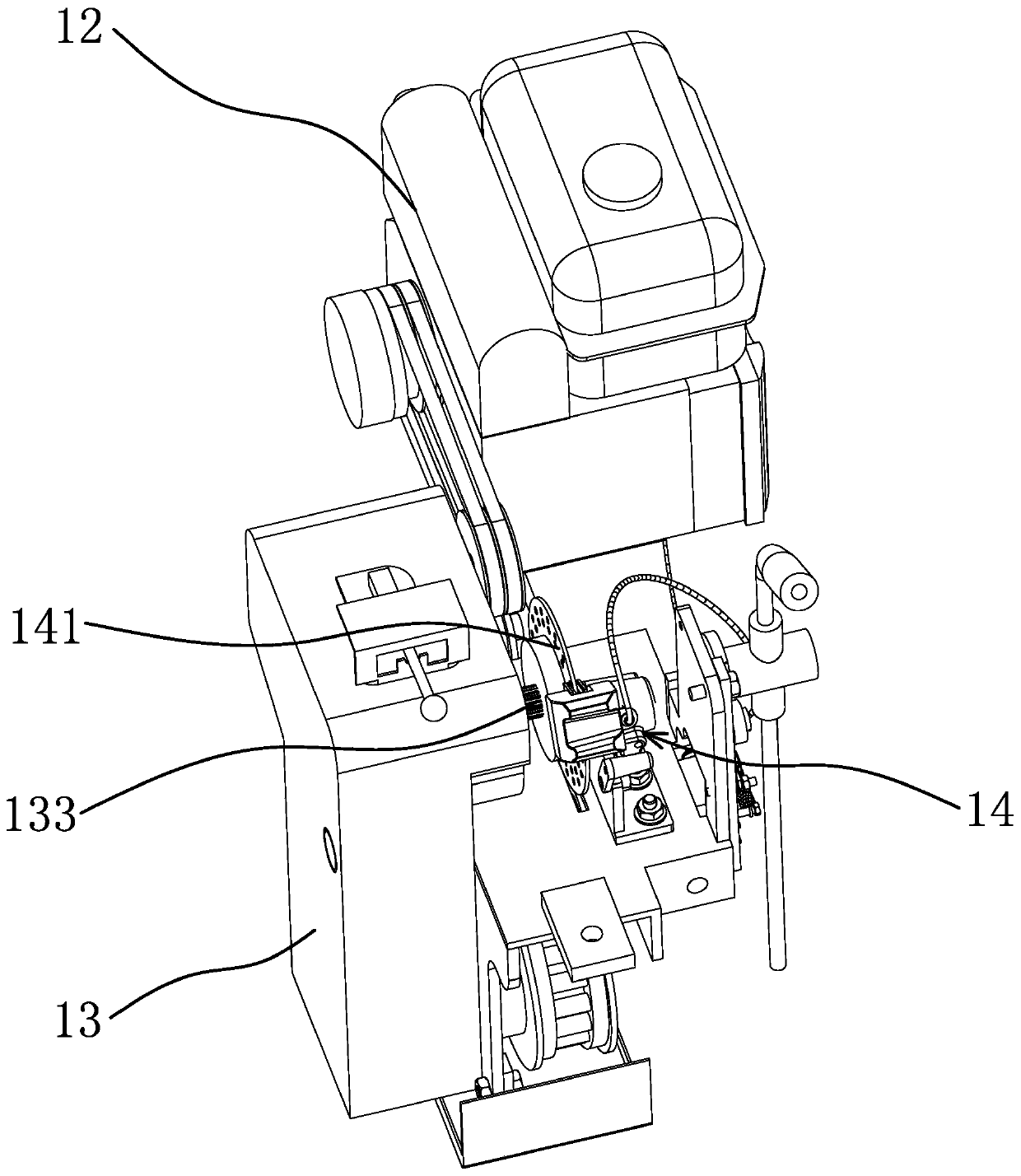

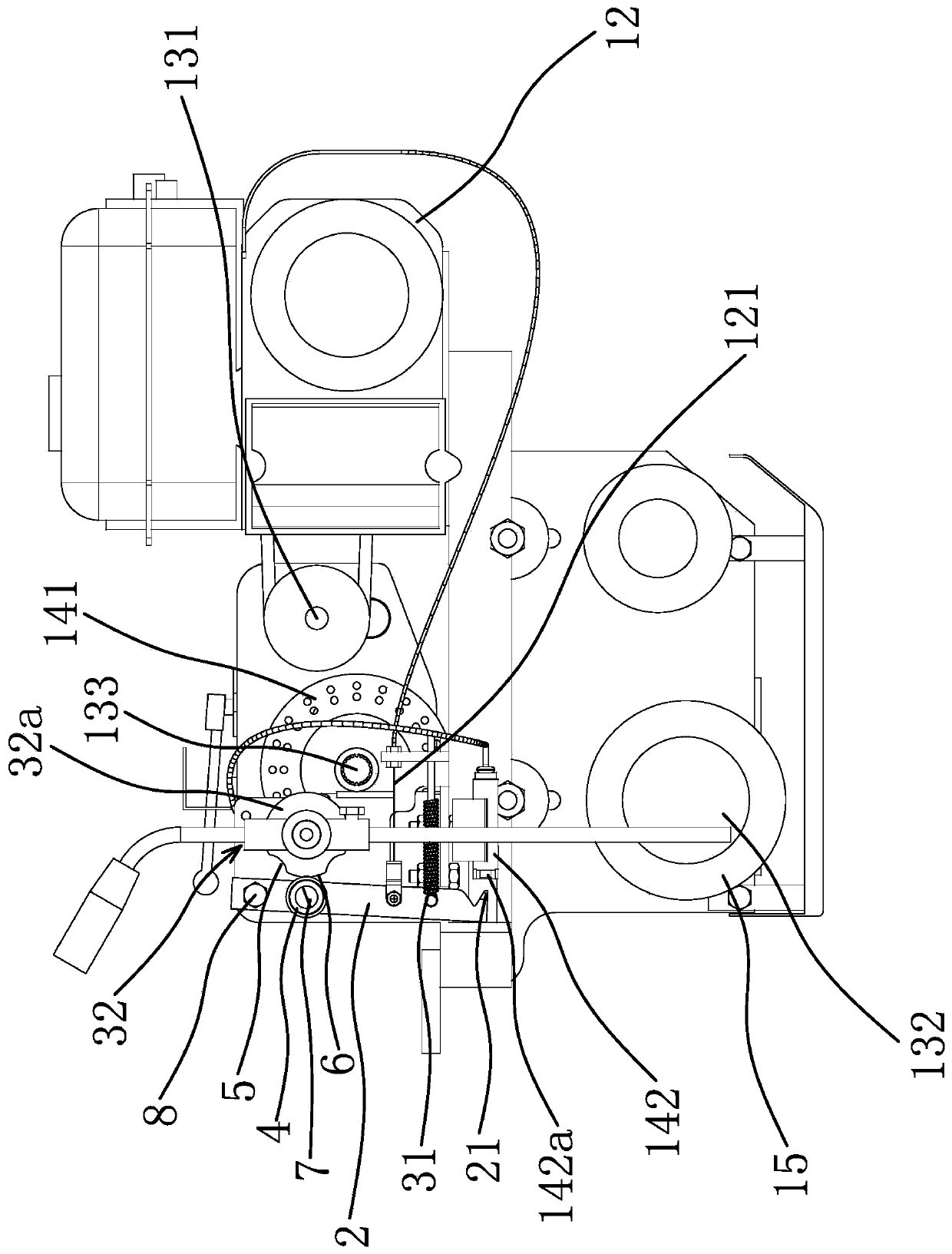

[0032] Such as figure 1 and Figure 8 Vegetarian food, this monorail transport machine includes head 1, track 9 and limit assembly 10, head 1 includes bracket 11, engine 12 and transmission box 13, engine 12 and transmission box 13 are fixed on the bracket 11, and transmission box 13 has Input shaft 131, output shaft 132 and brake shaft 133, input shaft 131, output shaft 132 and brake shaft 133 are synchronously driven in transmission case 13, engine 12 is connected with input shaft 131 transmission, output shaft 132 is provided with drive wheel 15. The machine head 1 is set on the track 9, the driving wheel 15 meshes with the track 9, and when the engine 12 outputs power, it is connected to the input shaft 131 through a belt transmission mechanism, and the rotation of the input shaft 131 drives the output shaft 132 and the brake shaft 133 to synchronize Rotating, the output shaft 132 drives the driving wheel 15 to rotate so that the machine head 1 moves up or down along the ...

Embodiment 2

[0040] The content of this embodiment is basically the same as that of the above-mentioned embodiment 1, the difference is that the disc brake 14 in this embodiment is a wire-pull disc brake, and the outer end of the steel wire that controls the locking and opening of the disc brake is connected with the swing rod 2 connect.

Embodiment 3

[0042] The content of this embodiment is basically the same as that of the above-mentioned embodiment 1, the difference is that: the drive assembly in this embodiment is a cylinder, the cylinder is installed on the bracket 11, the piston rod of the cylinder is connected with the swing rod, and the piston rod stretches to drive the swing rod 2 back and forth swing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com