Caterpillar traction type track equipment train

A technology for equipment train and crawler traction, which is applied to locomotives, earthwork drilling, transportation and packaging, etc. It can solve the problems of potential safety hazards such as wire rope traction, and achieves prevention of vehicle slippage and injury accidents, good adaptability, and reduced labor The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

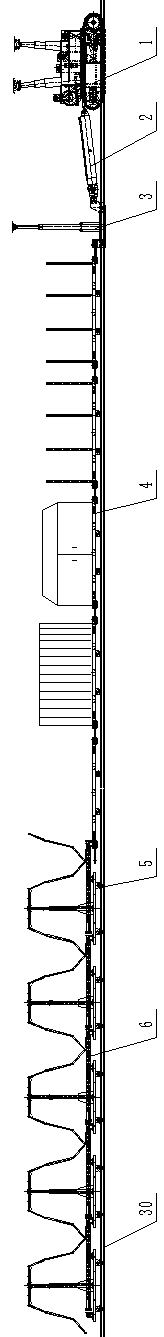

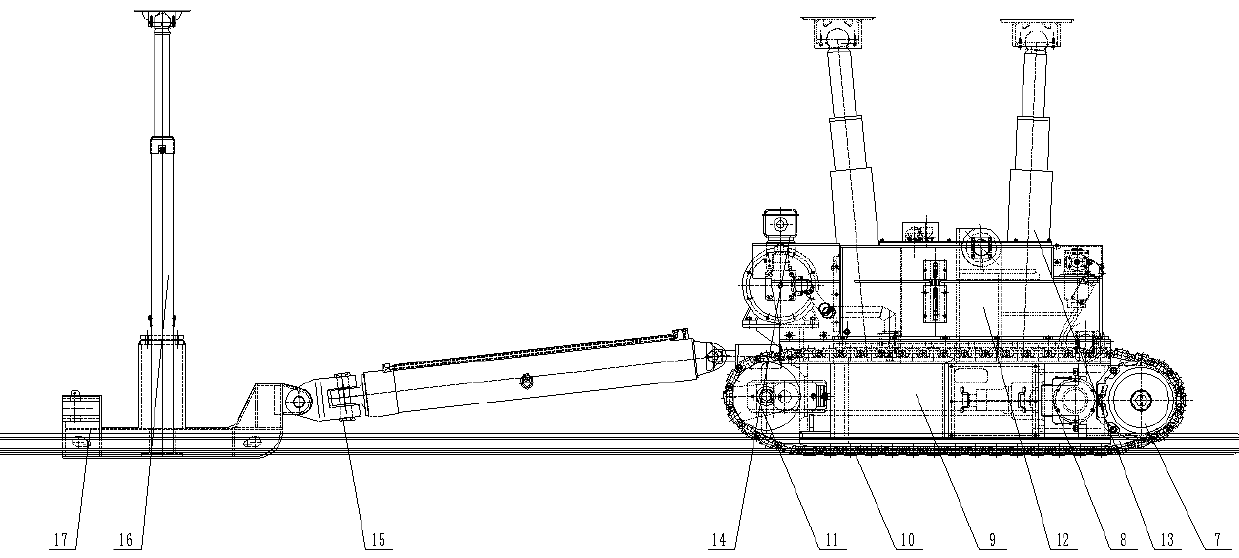

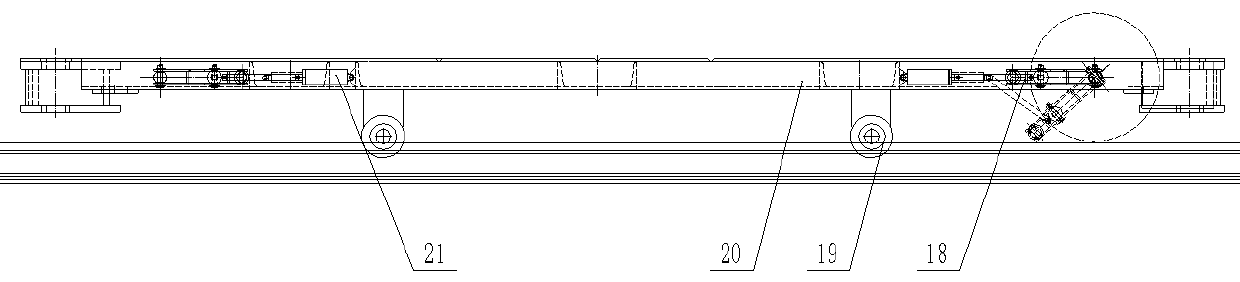

[0033] like figure 1 As shown, a complete set of crawler-tracted rail equipment train transportation equipment includes a crawler-type traction support 1, a traction cylinder 2, a mutual support device 3, a self-locking flatbed car 4 and a cable storage car 5. The crawler-type traction bracket 1 is located at the front end of the whole set of equipment, straddles the outside of the roadway rail 30, and is hinged with two traction cylinders 2, and the traction cylinder 2 is hinged with the mutual support device 3 through the cross joint 15. The mutual support device base is located on the sleepers in two root rails 30 inboards, and the rear part is connected with the self-locking flatbed car 4 by connecting plate. The wheel of self-locking flatbed car 4 is pressed above the track. Adjacent flat cars are connected by connecting plates. Last flat car tail end is welded with two connectors 29, links to each other with rear cable storage car 5 by two telescoping connecting rods 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com