Blocking failure judgment method of CFB (Circulating Fluidized Bed) boiler return system

A technology for fault judgment and material return, which is applied in the combustion method, the fuel burning in the molten state, and the geophysical measurement. It can solve the problems of poor timeliness of fault judgment, long cooling time, and high safety risks, and achieve accurate judgment and high safety. , to ensure the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The method for judging the clogging fault of the CFB boiler return system includes the following steps:

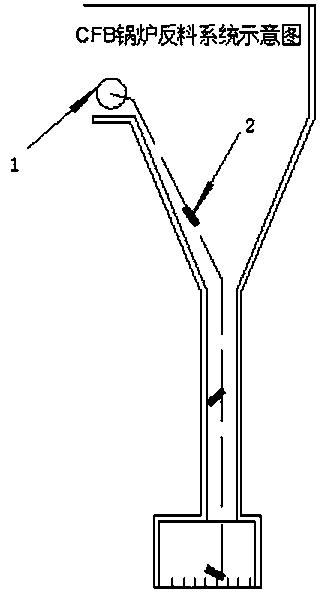

[0040] Step (1) The auscultation personnel carry the auscultation equipment and prepare at the return valve, and the detection object 2 release personnel carry 3 pieces of detection object 2 and prepare at the manhole 1 of the CFB boiler separator;

[0041] Step (2) After the auscultation personnel are ready for the auscultation, the auscultation personnel issue an instruction to release the detection object 2 to the detection object 2 release personnel;

[0042] Step (3) The test object 2 release personnel releases a piece of test object 2 into the separator; at the same time, the auscultation personnel at the return valve perform auscultation;

[0043] Step (4) After waiting for 1 minute, repeat steps (2) (3) until the detection substance 2 is released;

[0044] Step (5) Judge the inspection result.

[0045] The method for troubleshooting the clogging of the CFB...

Embodiment 2

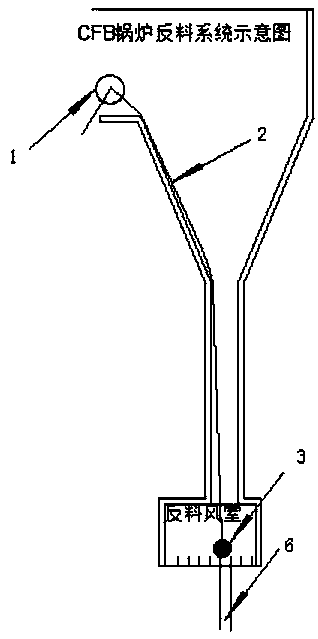

[0052] (1) One person with 23 test objects, 1 part of the contact equipment to the boiler separator manhole 1 is the person who released the test object 2; two people with auscultation equipment, and the contact equipment to the return valve are the auscultation personnel; (2) when After the auscultation personnel at the return valve are ready for auscultation, use the contact device to release the test object 2 at the separator to issue an instruction to release the test object 2; (3) The test object 2 release personnel releases a piece of the test object 2 into the separator after hearing the instruction Test object 2; auscultate at the return valve. Two people judge whether the return system is blocked according to whether they hear the sound of test object 2 hitting the return air distribution plate; (4) Wait for one minute and repeat (2) (3) Step until the detection substance 2 is released; (5) Judging the inspection result.

[0053] After the release of the three pieces ...

Embodiment 3

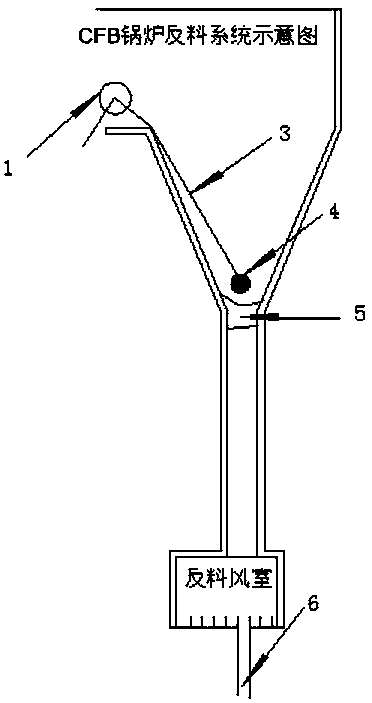

[0057]Implementation steps: (1) One person takes one piece of contact equipment to the ash discharge pipe 6 in the return air chamber as an observer, opens the valve 6 of the ash discharge pipe in the return air chamber, and vents the remaining ash in the return air chamber; (2) two One part of the contact device, the special return device detection and dredging device to the manhole 1 of the boiler separator as dredging personnel; (3) After the return valve is emptied, the dredging personnel will carry the dredging device with the heavy object 4 from the separator. Put hole 1 to the blockage position of the boiler return system, and fix the other end outside the furnace; at this time, the dredging personnel judge the blockage position according to the length of the dredging device (this method can also be used as a method for judging the blockage fault of the CFB boiler return system); ( 4) The dredging personnel lift and lower the dredging device repeatedly, so that the heavy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com