A sensor environment setting device and a sensor parameter calibration system

A sensor and environmental technology, applied in force/torque/power measuring instrument calibration/testing, instruments, measuring devices, etc., can solve the problems of low efficiency of pressure sensor calibration, reduced calibration effect, long time, etc., to improve production capacity , improve the degree of automation, and ensure the effect of the calibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] To make the objectives, technical solutions and advantages of the present invention will become more apparent, both embodiments referring to the drawings, the present invention is described in further detail.

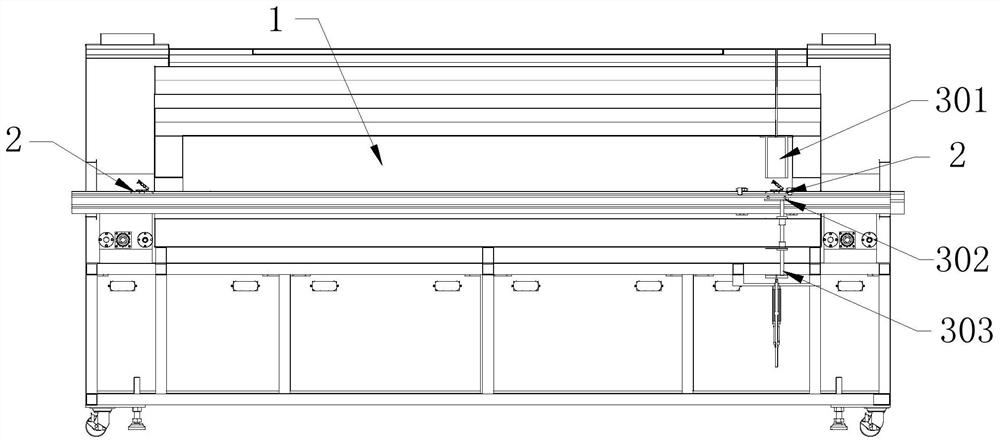

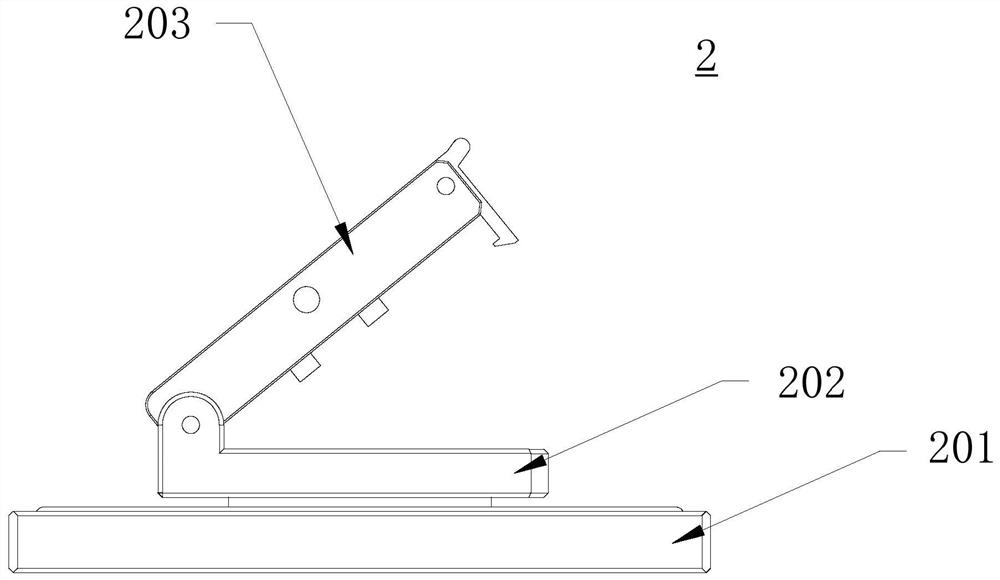

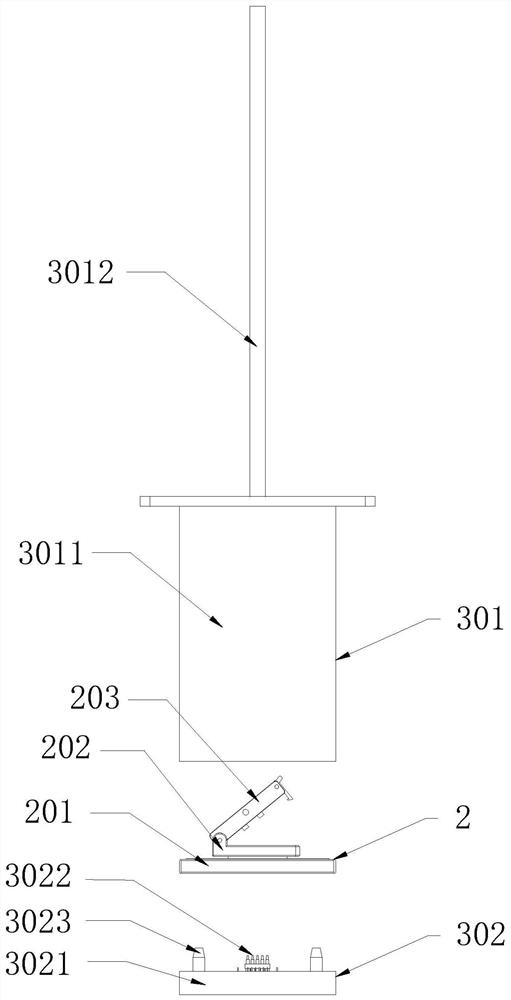

[0057] like figure 1A sensor shown in the schematic configuration example of an environment setting device of the embodiment of the present invention, the sensor device comprises a temperature controlled environment setting region 1, stage 2 and the pressure regulator 3 and the connecting means. Wherein the stage 2 carrying a conveying means for driving by a sensor, to move in the zone 1 thermostat. The regulating thermostat and the connecting means are located in zone 1, when the stage 2 is moved and connected to the pressure regulating means and a regulating means connected to the sensor carrier stage 2 was carried and placed on the setting pressure sensor electrically connected to the setting device is located outside the environment monitoring sensor parameters a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com