Tomato crushing and filtering device

A filter device and tomato technology, applied in grain processing, juice extraction, food science, etc., can solve the problems of increased production cost of tomato pulp, poor crushing effect and filtering effect, low filtering efficiency and prolonging production time, etc., so as to facilitate collection, Improve the crushing efficiency and ensure the crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

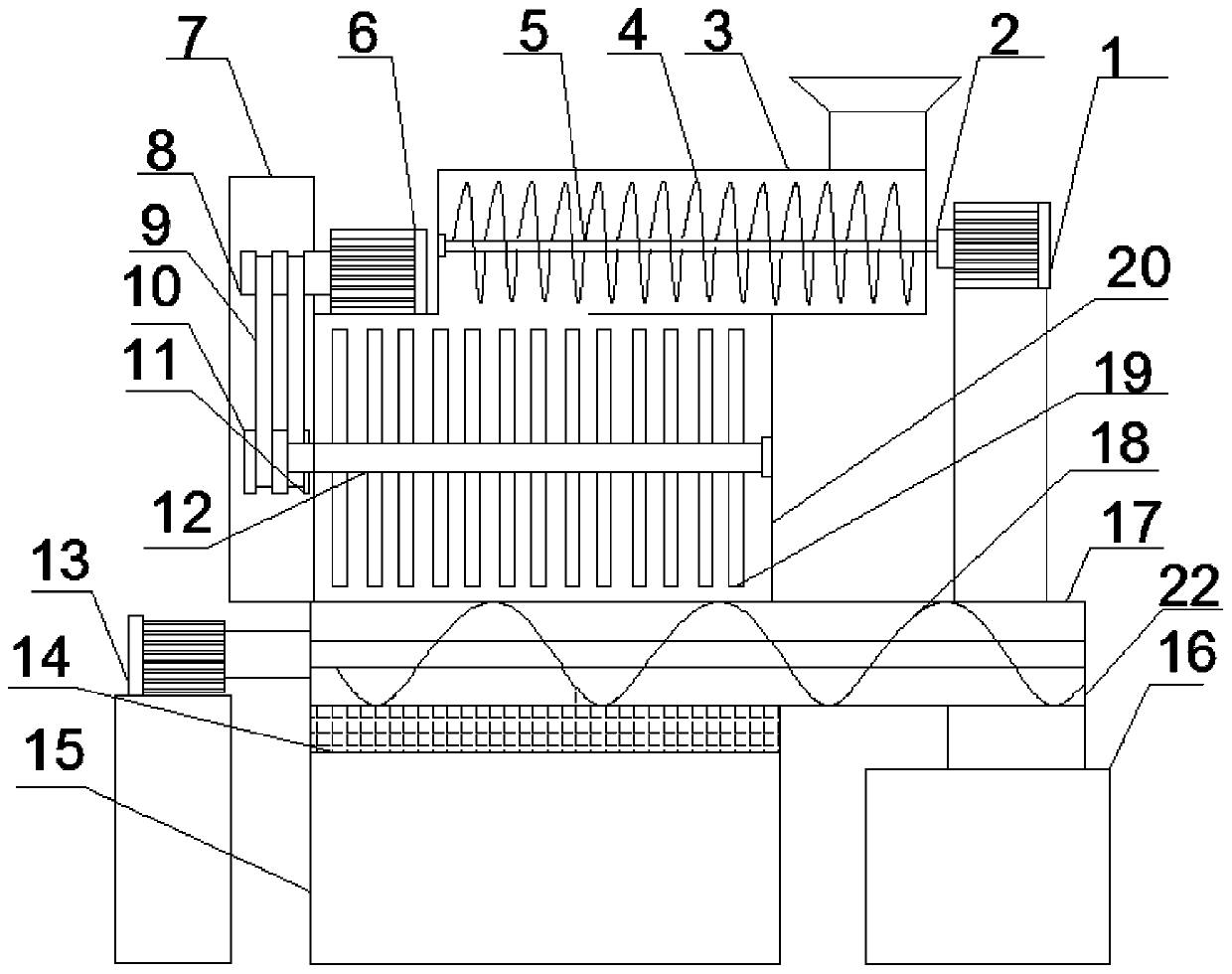

[0028] A tomato crushing and filtering device, comprising a first crushing box 3, the bottom of the first crushing box 3 is provided with a secondary crushing box 20, the upper part of the secondary crushing box 20 is provided with a secondary crushing motor 6, and the secondary crushing box 20 is provided with a secondary crushing motor 6. The lower part of the crushing box 20 is provided with a mobile device 17, the lower part of one side of the mobile device 17 is provided with a first collection box 15, the first collection box 15 is provided with a filter screen 14, and the other side of the mobile device 17 is provided with a Second collection box 16.

[0029] working principle:

[0030] Firstly, tomatoes are put into the first crushing box 3, and then crushed by the secondary crushing box 20 after passing through the first crushing box 3. By arranging the first crushing box 3 and the secondary crushing box 20, the tomato is broken twice to ensure that the tomato meat c...

Embodiment 2

[0032] On the basis of Embodiment 1, a first crushing motor 1 is provided on one side of the first crushing box 3, the first drive shaft 2 of the first crushing motor 1 is connected to one end of the crushing shaft 5, and the crushing The other end of the shaft 5 extends into the first crushing box 3 , and the crushing shaft 5 in the first crushing box 3 is provided with a screw blade 4 . During use, open the first crushing motor 1, the work of the first crushing motor 1 drives the first drive shaft 2 to rotate, and the first drive shaft 2 drives the crushing shaft 5 to rotate, and the crushing shaft 5 drives the screw blade 4 to rotate. By setting the screw blade 4, the tomatoes can be crushed, and the crushed tomatoes can be moved, and the crushing can be continued without affecting subsequent crushing of the tomatoes.

Embodiment 3

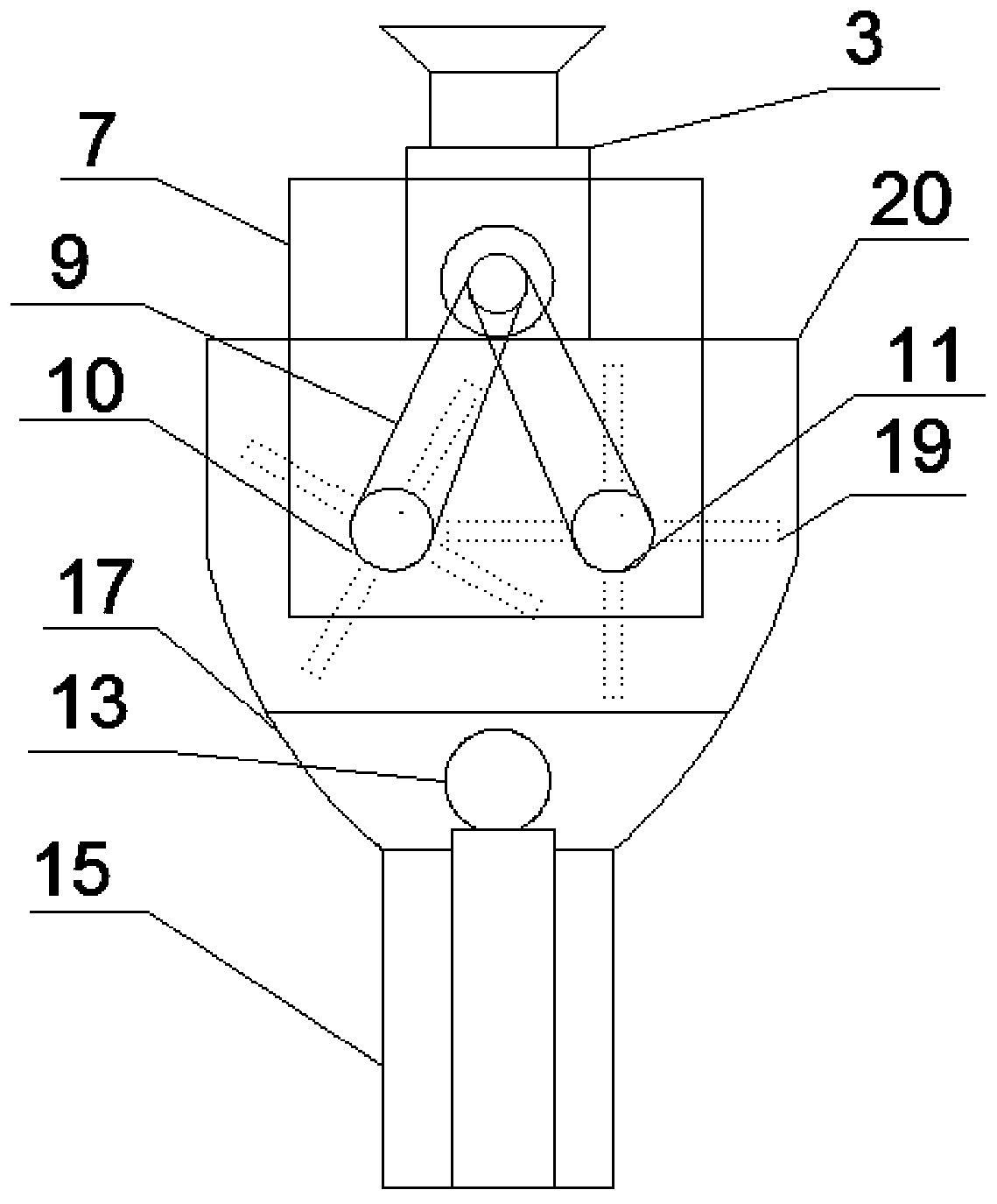

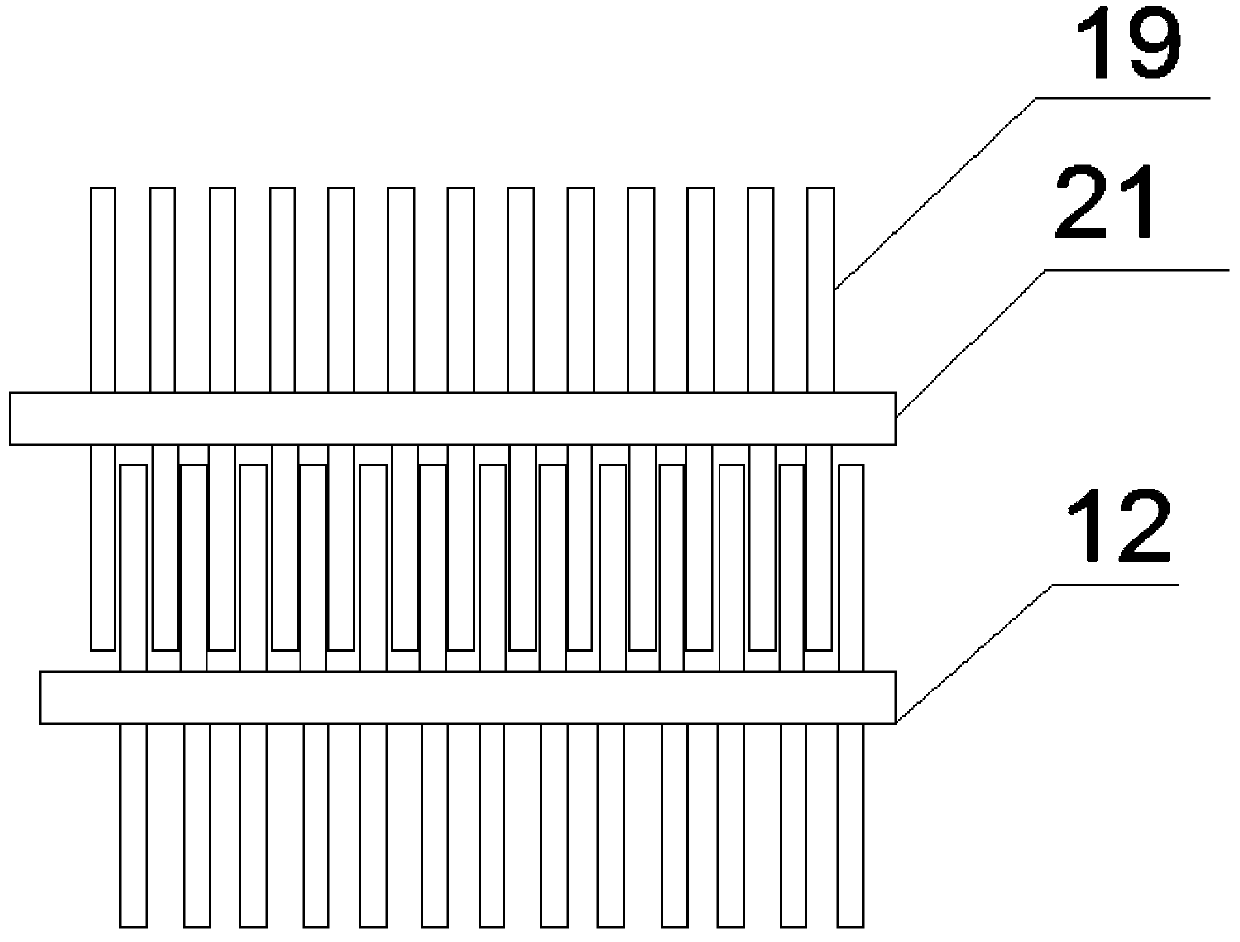

[0034] On the basis of Embodiment 1, the second drive shaft 8 of the secondary crushing motor 6 is connected to one end of two belts 9, and the other ends of the two belts 9 are connected to the first driven wheel 10 and the second driven wheel 10 respectively. The driven wheel 11 is connected, the first driven wheel 10 is connected with the first roller shaft 12, the second driven wheel 11 is connected with the second roller shaft 21, and the first roller shaft 12 and the second roller shaft 21 both extend Into the secondary crushing box 20 and provided with roller knives 19, the roller knives 19 on the first roller shaft 12 and the second roller shaft 21 are arranged alternately. By arranging the first roller shaft 12 and the second roller shaft 21, the roller knife 19 can crush tomatoes, ensuring the crushing effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com