Fruit size classifying device and classifying process thereof

A kind of classification equipment and fruit technology, applied in classification, solid separation, chemical instruments and methods, etc., can solve the problems of complex collection procedures, fruit damage, large errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

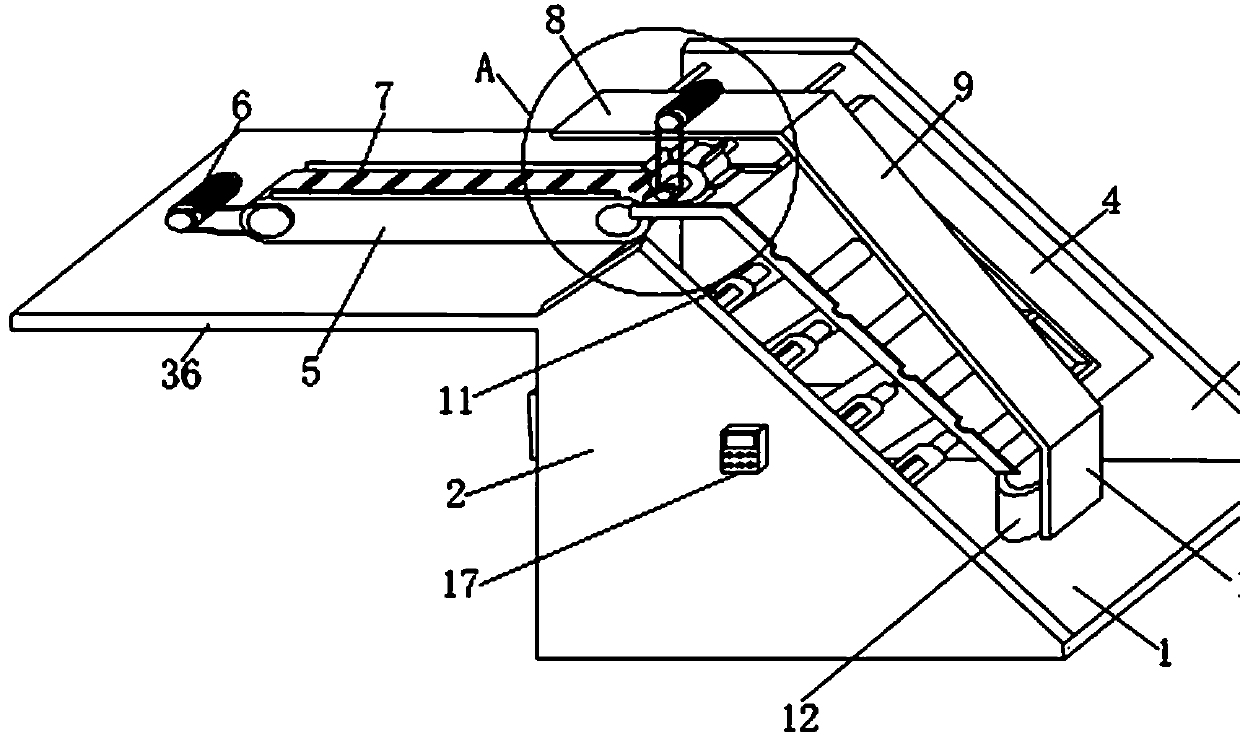

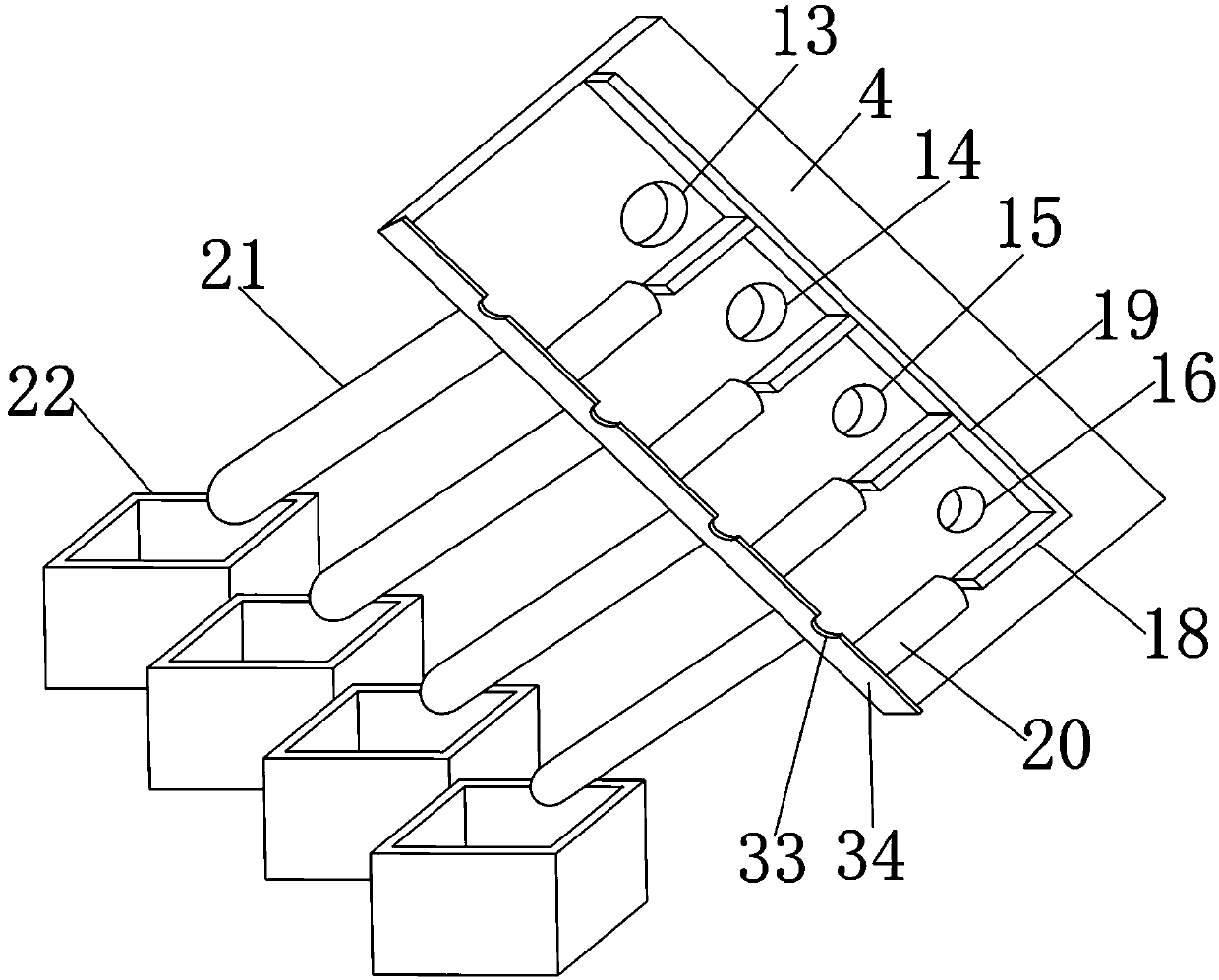

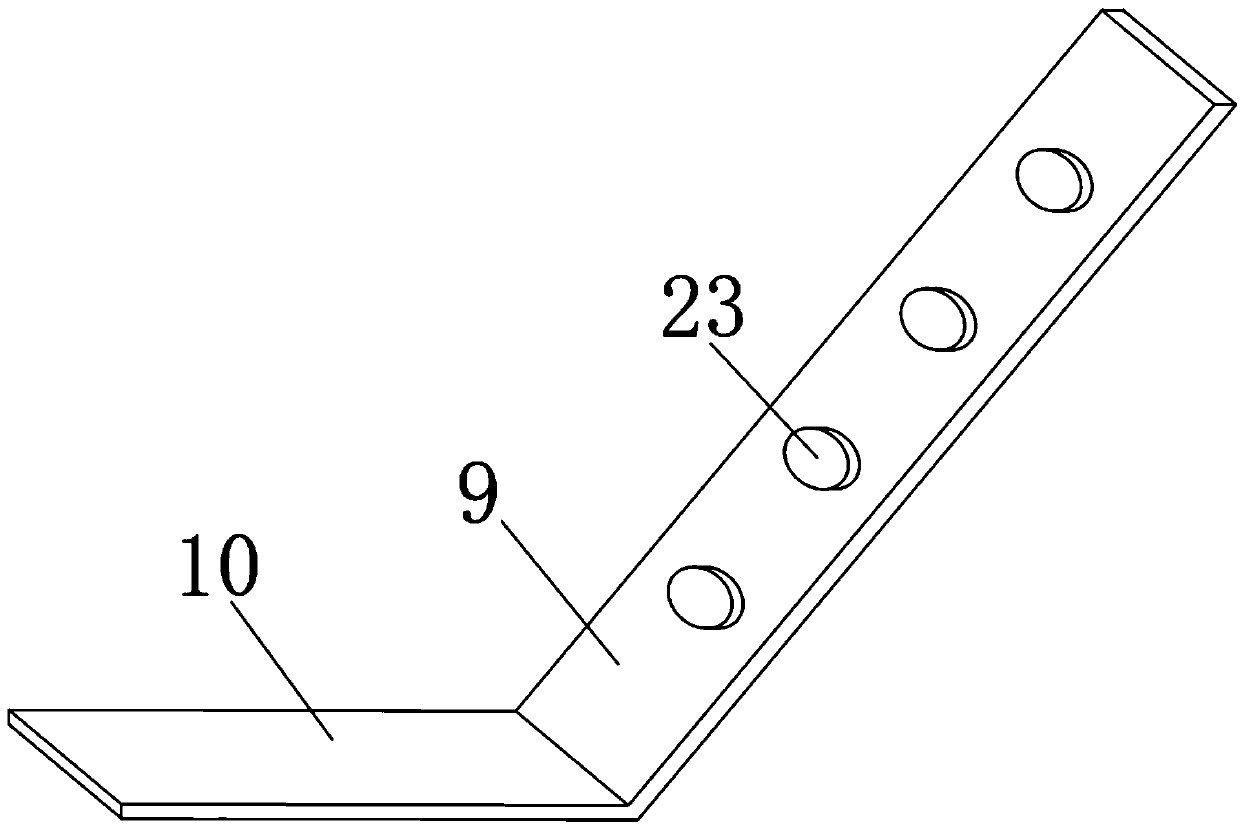

Embodiment 1

[0030] Such as Figure 1-3As shown, a kind of fruit size sorting equipment comprises a lower bottom plate 1, a No. 1 side plate 2 and a No. 2 side plate 3, the upper end of the lower bottom plate 1 is fixedly equipped with a support plate 10 and a collection box 12, and the upper end of the support plate 10 is fixedly installed The limit plate 9 is provided with four groups of electric valve switches 23 at the lower end of the limit plate 9, and four groups of cylinders 11 are provided at the rear end of the No. The front end of plate 3 is fixedly installed with inclined plate 4, and the upper end of inclined plate 4 is respectively fixedly installed with four groups of blocking blocks 20 and four groups of No. 1 blocking plates 18, and No. 1 blocking plate 18 is positioned at the rear end of blocking block 20, and the inclined plate The upper end of 4 is respectively provided with No. 1 through hole 13, No. 2 through hole 14, No. 3 through hole 15 and No. 4 through hole 16, a...

Embodiment 2

[0037] A sorting process of fruit size sorting equipment, the specific steps are as follows:

[0038] A: Put the fruit on the conveyor belt 5, place a piece of fruit between the adjacent equally divided plates 7, the conveyor belt 5 will transport the fruit to the conveyor plate 32 under the drive of the No. Toggle on the inclined plate 4, so that the fruits can enter the inclined plate 4 at equal intervals for size classification;

[0039] B: The fruit enters the inclined plate 4 and slides down from the upper end of the inclined plate 4 under the action of its own gravity. According to the difference of the size of the fruit, the positions where the fruits are tangent to the inclined plate 4 and the limit plate 9 are also different, which is relatively Small fruits will pass through the blocking block 20 successively, and larger fruits will be blocked by the blocking block 20 under the extrusion force of the inclined plate 4 and the limiting plate 9, so that according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com