A system for realizing afterburning cycle engine and thrust depth adjustment method

An engine and thrust technology, which is applied in the direction of machines/engines, rocket engine devices, mechanical equipment, etc., can solve the problems of low adaptability of components, difficult adjustment of thrust depth, complex thrust adjustment scheme, etc., to achieve afterburning cycle engines The thrust depth adjustment method is simple and reliable, which reduces the design difficulty and reduces the effect of changing the range of working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

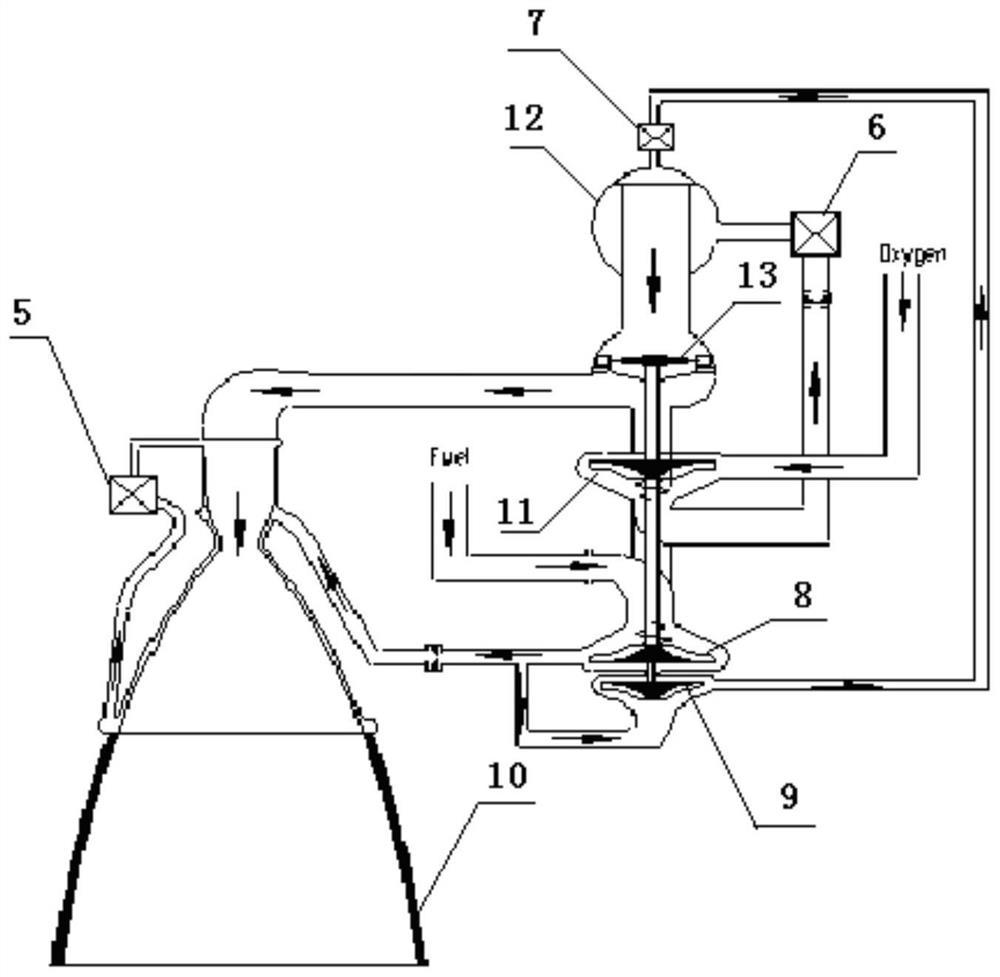

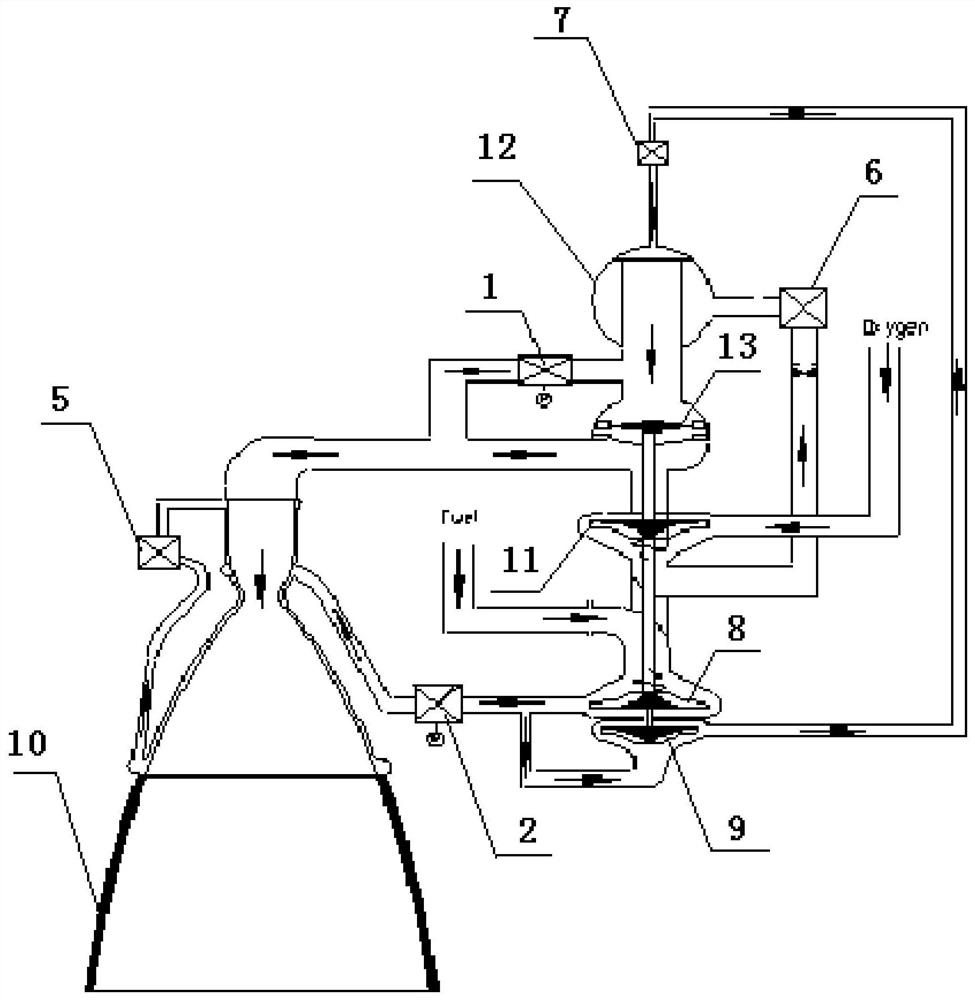

[0047] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0048] The invention discloses a method for adjusting the thrust depth of an afterburning cycle engine by using oxygen-enriched gas propulsion. When the afterburning cycle engine is working, the fuel entering the gas generator through the fuel path of the gas generator and the fuel entering the gas generator through the oxidant supply path The oxidant is burned, and the oxygen-enriched gas produced drives the main turbine to work, drives the main turbine to rotate, and enters the thrust chamber through the thrust chamber gas supply path to generate thrust; the engine stays in the state of propulsion of the oxygen-enriched gas alone to maintain a low-thrust working condition, and needs to enter the main turbine. When working in the first-level working condition, the fuel main valve of the thrust chamber is opened, and the fuel enters the thrust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com