A bearing ring grabbing chuck

A technology for grabbing chucks and bearing rings, applied to chucks, manufacturing tools, manipulators, etc., can solve the problem of no protection for permanent magnets, and achieve the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

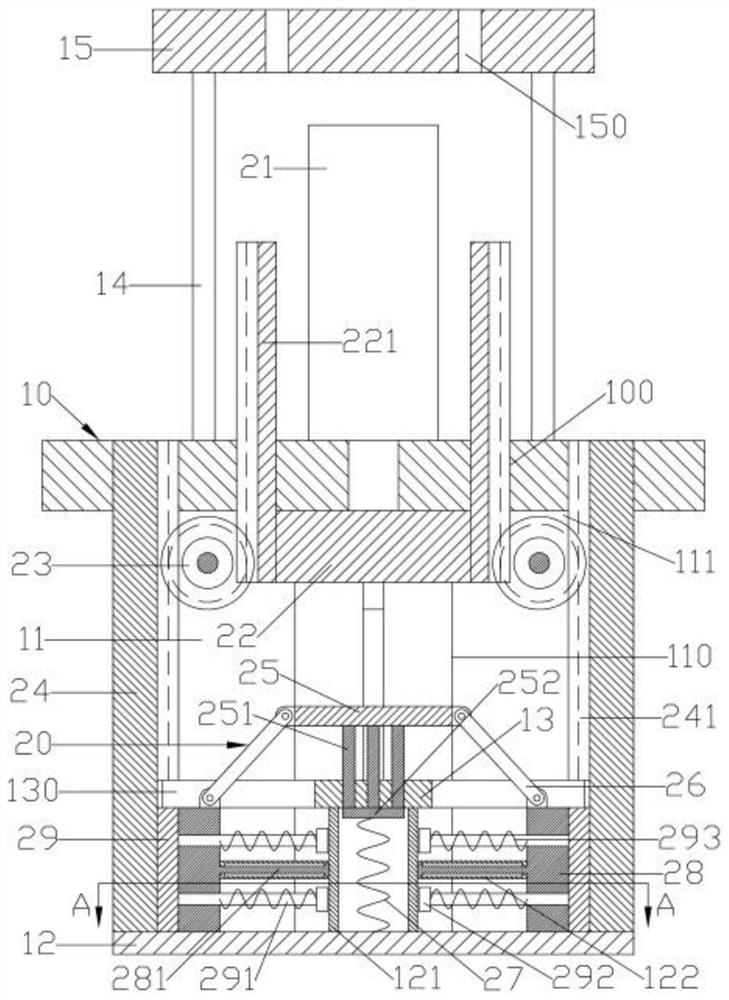

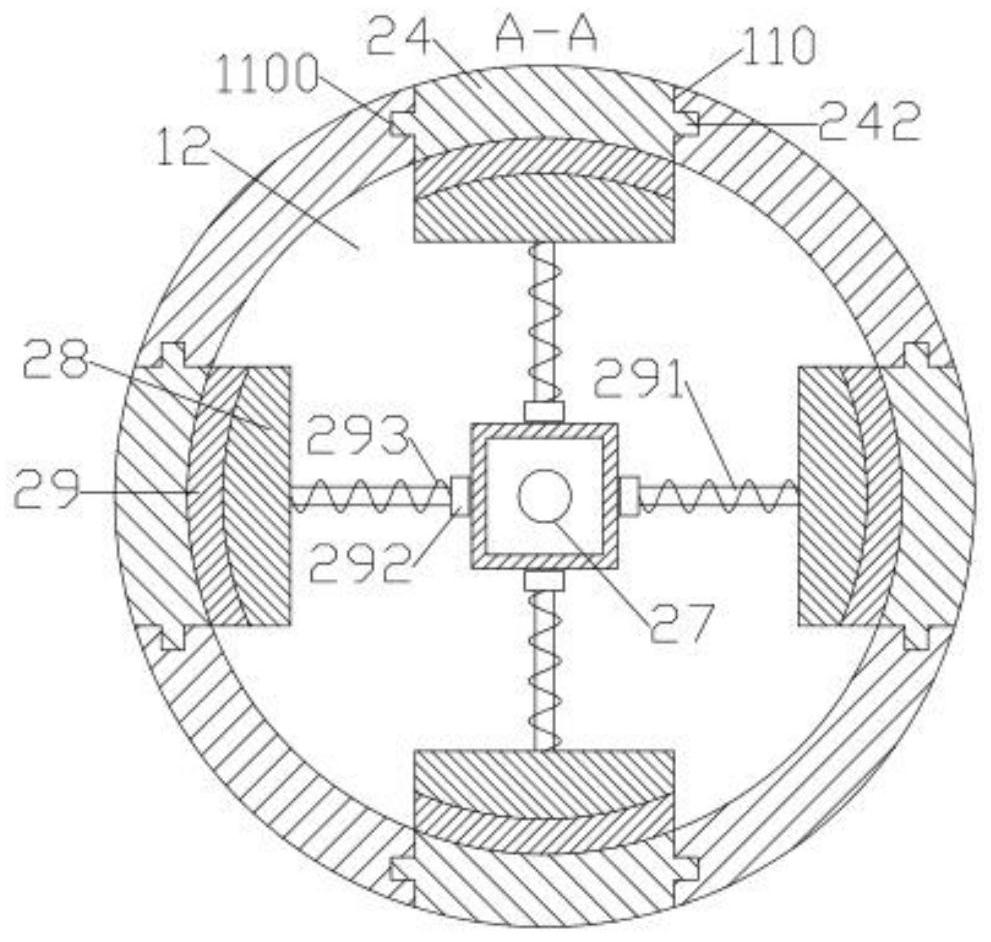

[0014] Specific implementation methods such as figure 1 , figure 2 As shown, a bearing ring grab chuck includes a circular plate-shaped central support plate 10; the lower end surface of the central support plate 10 is formed with a lower support cylinder 11 coaxially provided with a circular cylindrical shape; The bottom of the support tube 11 is formed with a lower support plate 12; the side wall of the lower support tube 11 is formed with a number of evenly distributed radially extending rectangular hole-shaped vertical telescopic slots 110; the upper end of the vertical telescopic slot 110 penetrates upwards Central support plate 10; the center of the upper end surface of the central support plate 10 is fixed with a lift cylinder 21; the piston rod of the lift cylinder 21 penetrates the center support plate 10 downwards and is fixed with a circular plate-shaped lift support plate 22; a vertical telescopic groove 110 The inner lift is provided with a guard plate 24 made o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com