Adjustable grey cloth conveying device based on hydraulic transmission

A transmission device and hydraulic transmission technology, which is applied in transportation and packaging, conveyors, loading/unloading, etc., can solve the problems of low production efficiency and high work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific operation mode of the present invention will be further described below in conjunction with accompanying drawings.

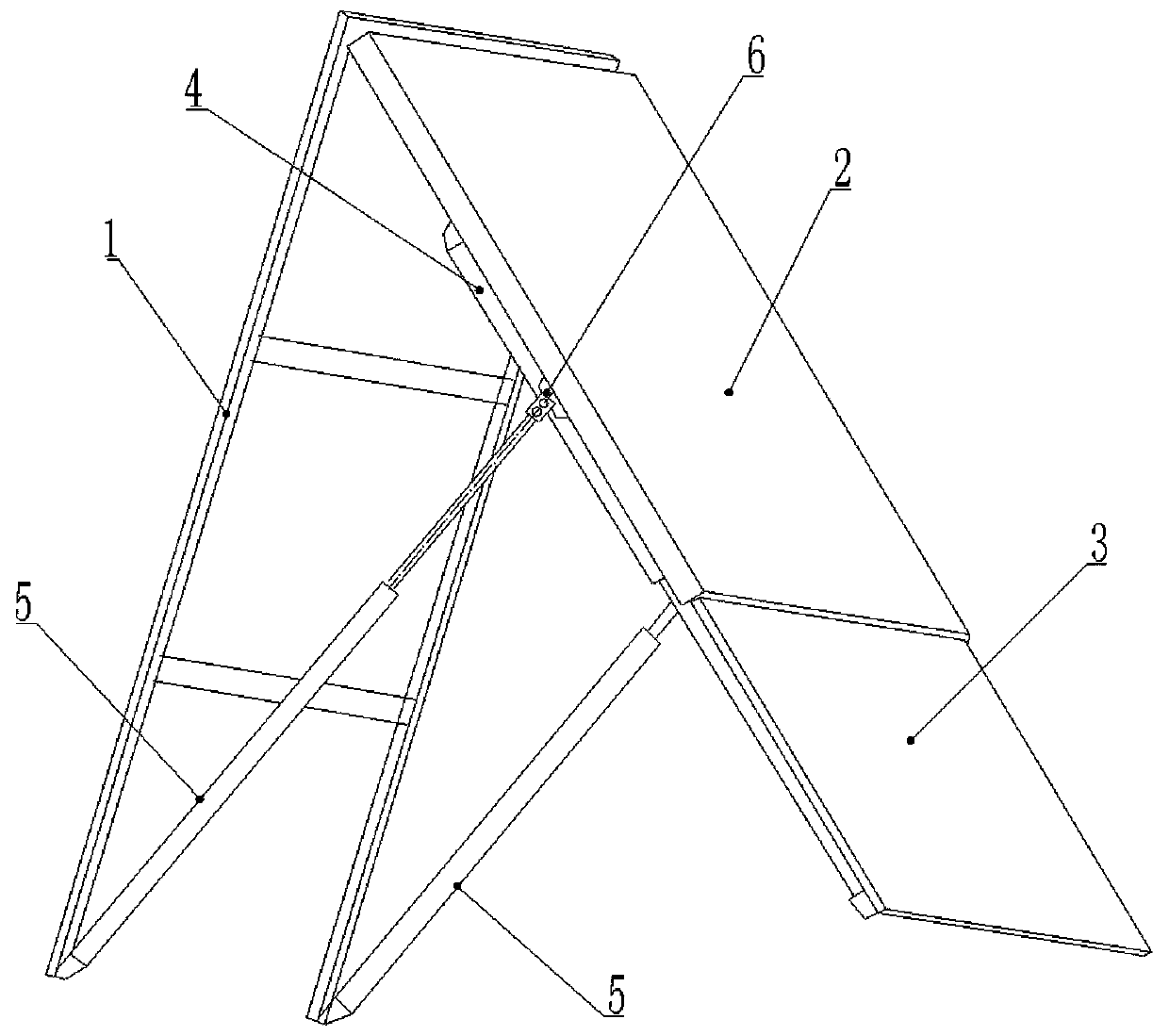

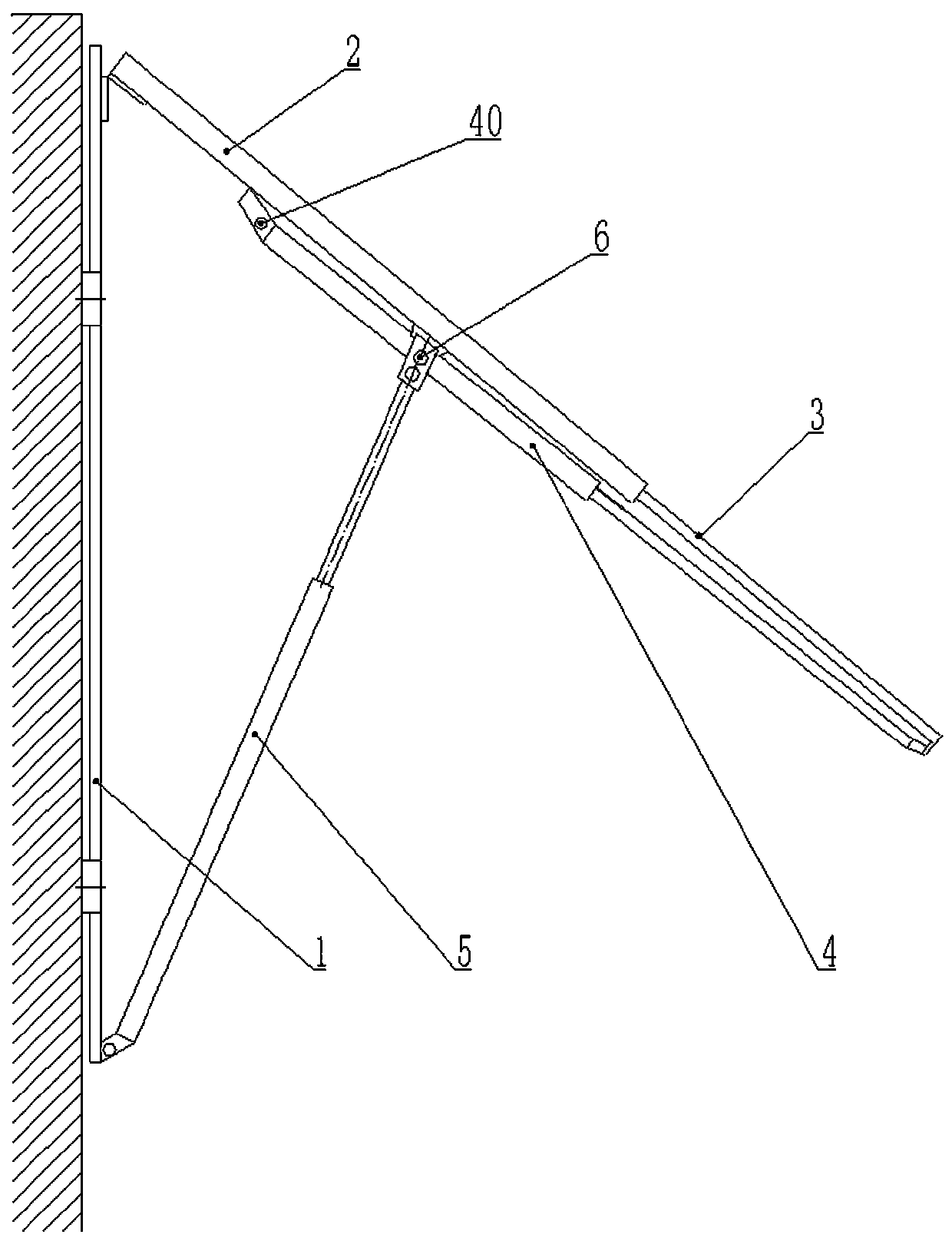

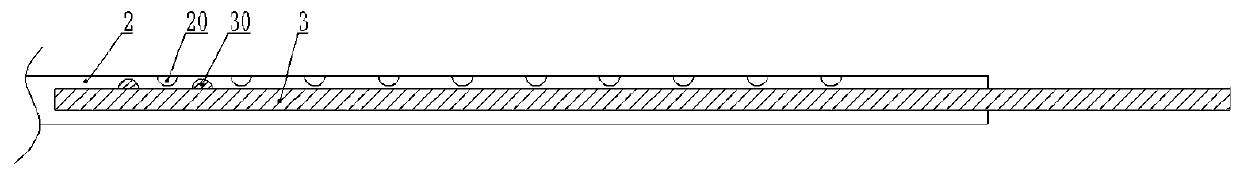

[0011] Such as figure 1 , figure 2 It can be seen that the adjustable gray cloth transmission device based on hydraulic transmission of the present invention includes a rectangular support 1, and the upper end of the support 1 is connected with a drawer box 2 through a hinge, and the outer surface of the drawer box 2 is set as a rear end transmission On the surface, the inside of the pumping box 2 is provided with a pumping plate 3, and the outer surface of the pumping plate 3 is set as the front transmission surface, and the rear transmission surface and the front transmission surface match each other; in the pumping box 2 1. A pair of extension oil cylinders 4 are arranged on both sides below the pumping plate 3, one end of the extending oil cylinders 4 is hinged to the middle end of the pumping plate box 2 through a hinge point 40, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com