Piston type valve element structure combining rigid ring surface with flexible base surface and method thereof

A technology of piston valve and rigid ring, which is applied to the device for pressure relief on the sealing surface, lift valve, valve details, etc., can solve the problem of unbalanced force on the piston valve core, and achieve the guarantee of sealing performance, Easy to manufacture and simple in structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

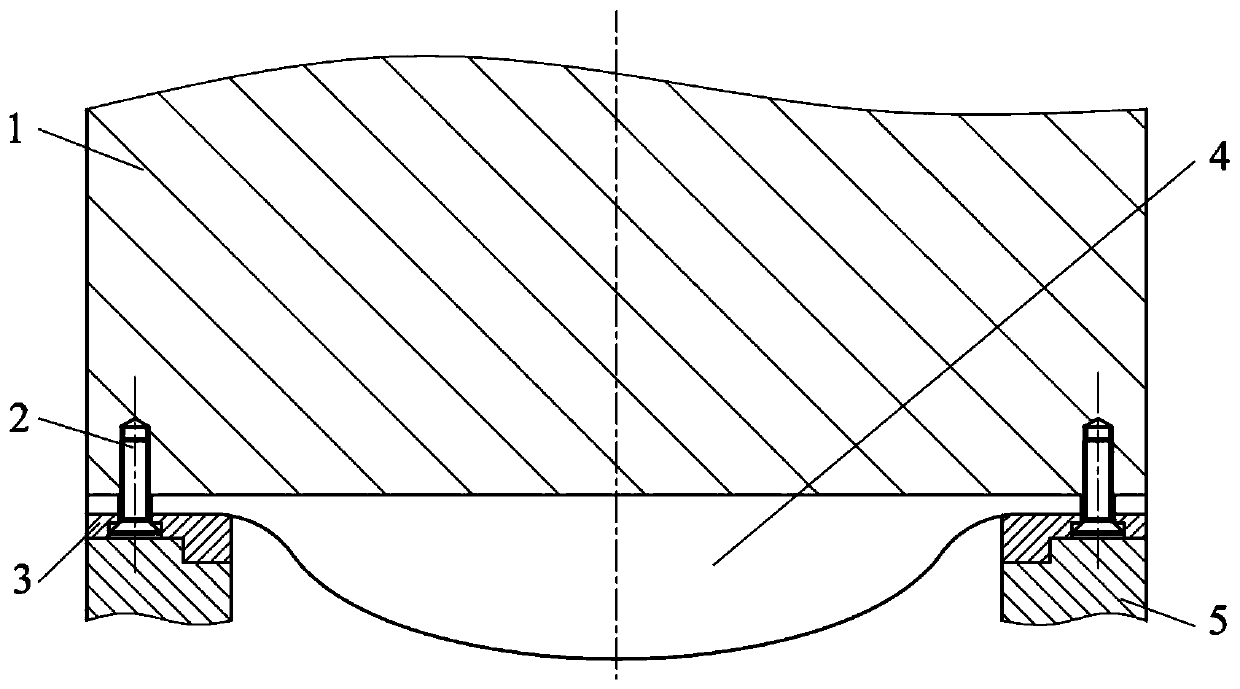

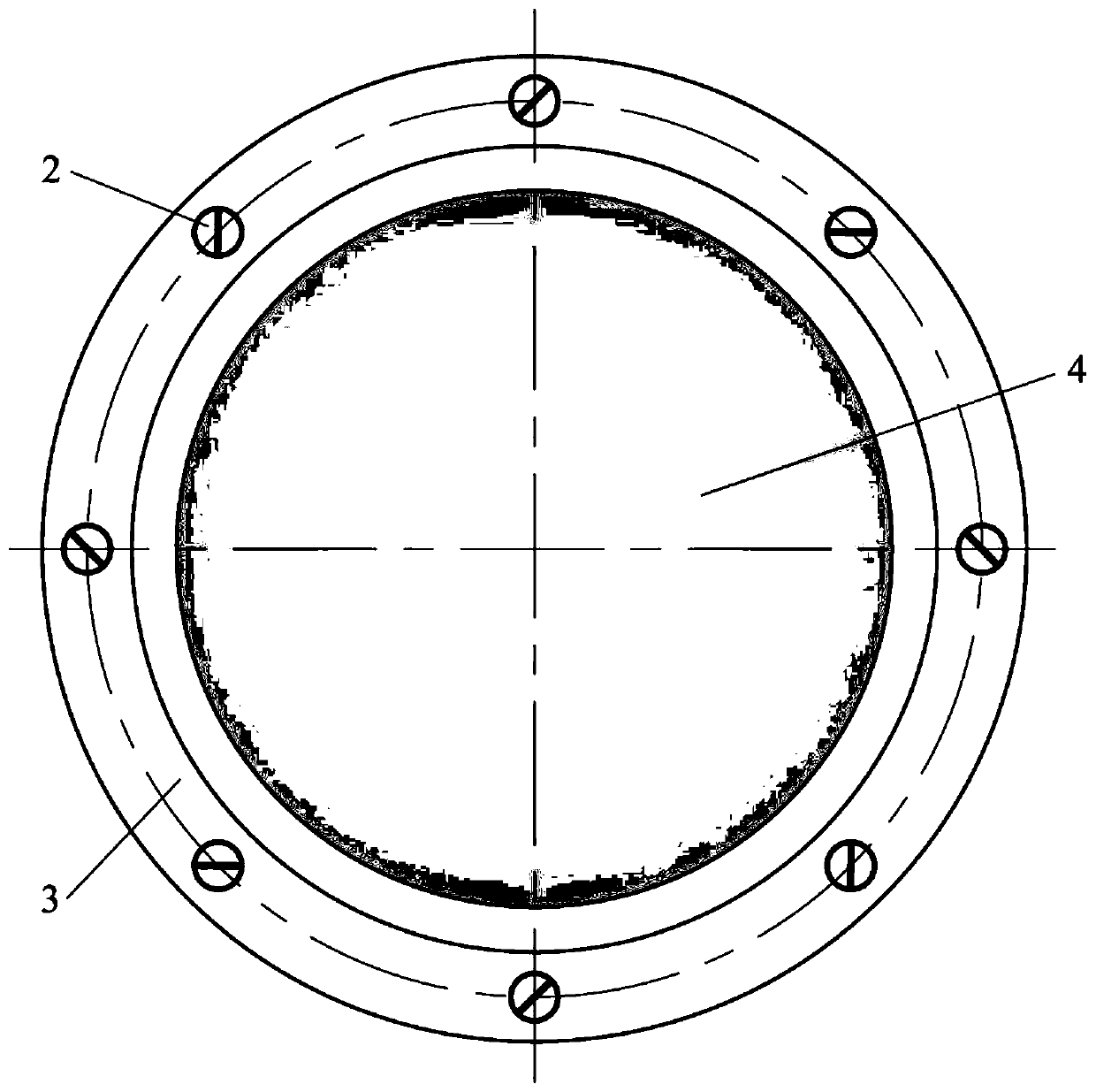

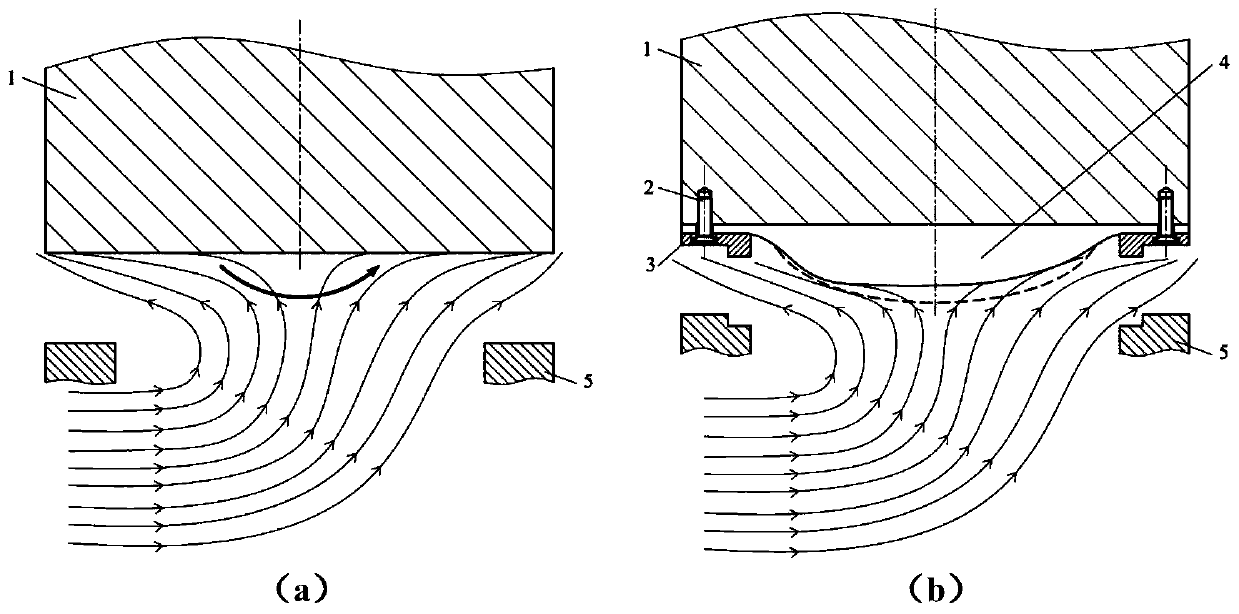

[0025] like figure 1 , figure 2 Shown is a piston-type spool structure with a rigid annular surface combined with a flexible base surface in a preferred embodiment of the present invention, and the piston-type spool structure is used to be installed above the valve seat 5 . Its main structure includes a connecting piece 2 and a piston valve core 1 , a flexible base surface 4 and a rigid ring surface 3 which are stacked and assembled sequentially from top to bottom.

[0026] Wherein, the piston type spool 1 is in the form of a cylinder with a flat bottom surface. The flexible base surface 4 is an irregular convex surface with thin edges and thick middle. The edge is used as a fixed part. The flexible base surface 4 is made of flexible material, which can deform when the bottom surface is subjected to external force. In this embodiment, the material of the flexible...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com