High-rigidity switching mechanism of optical lens group of crank slide block

A technology of crank slider and switching mechanism, applied in the field of optical instruments, can solve problems such as poor support stiffness, and achieve the effects of improving stability, small structure space size, and improving structure support stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

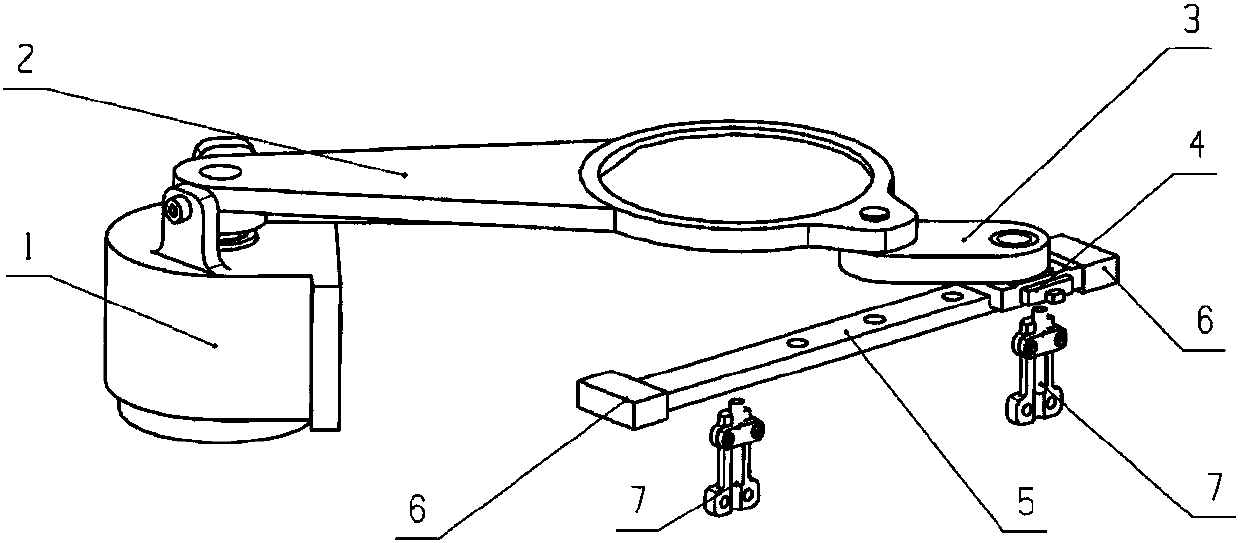

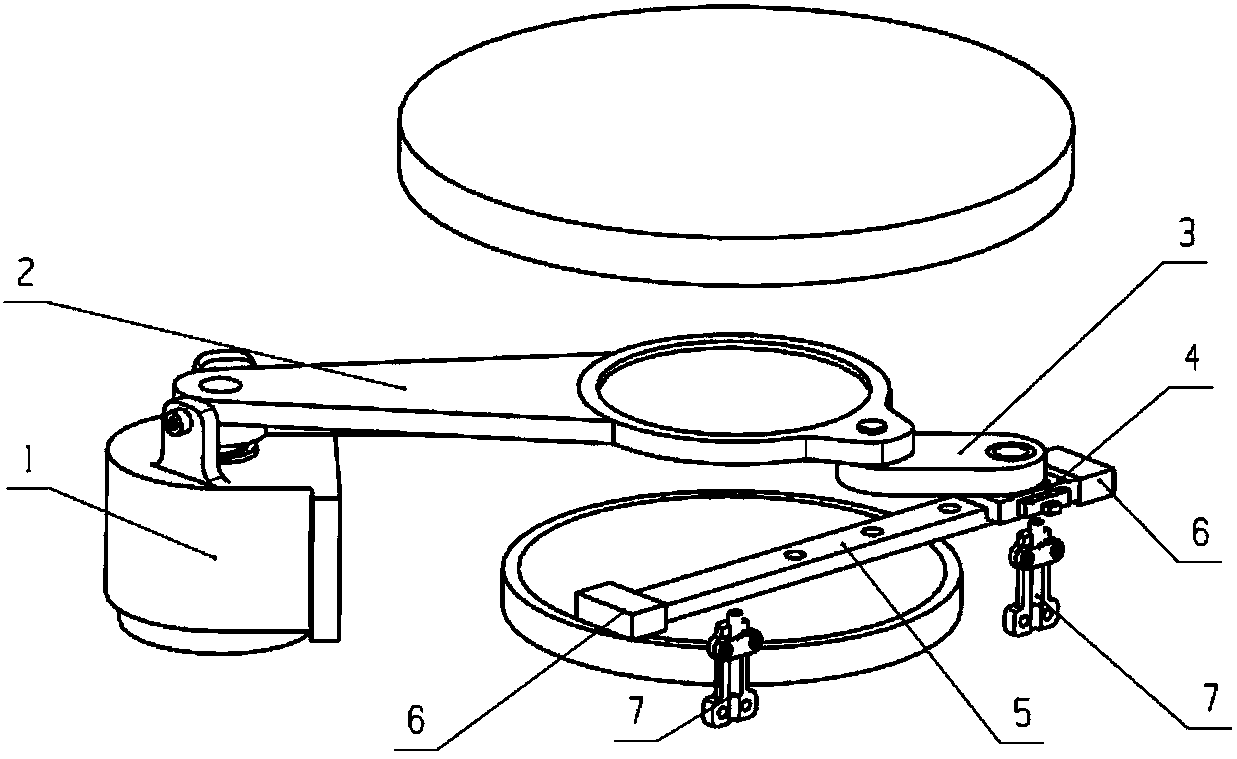

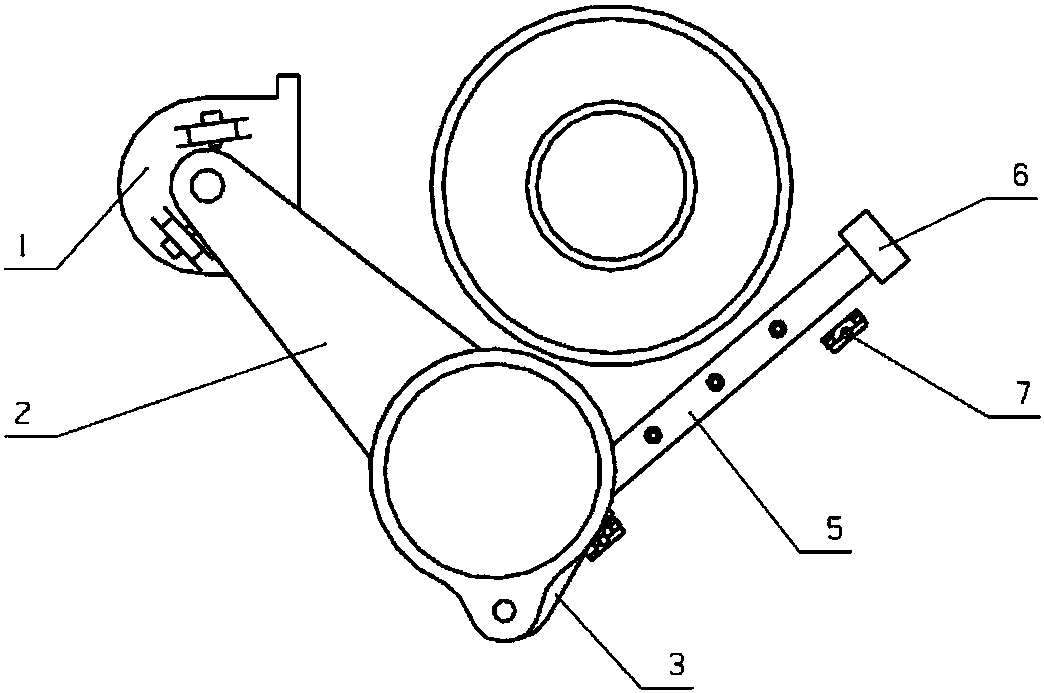

[0042] Such as figure 1 , figure 2 and image 3 As shown, the rotary drive device 1, the linear guide rail 5 and the proximity sensor 7 need to be independently installed on the outer casing of the equipment, and their mutual positions may need to be adjusted during assembly.

[0043] Such as Figure 4 As shown, the rotary driving device 1 is composed of a motor housing 11 , a motor 12 , an adapter bush 13 , a drive shaft 14 , a bearing bush 15 , a bearing 16 and a limit screw 17 . The motor housing 11 is the main structural part of the entire rotary drive device 1 , the stator of the motor 12 is fixed on the motor housing 11 , and the two are generally threaded. The rotor of the motor 12 is coupled with the drive shaft 14 through an adapter bush 13 . When the torque is small, the drive shaft 14 and the adapter bushing 13 can be used for interference fit, and when the torque is large, it is necessary to increase the flat key to transmit the torque. The adapter bushing 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com